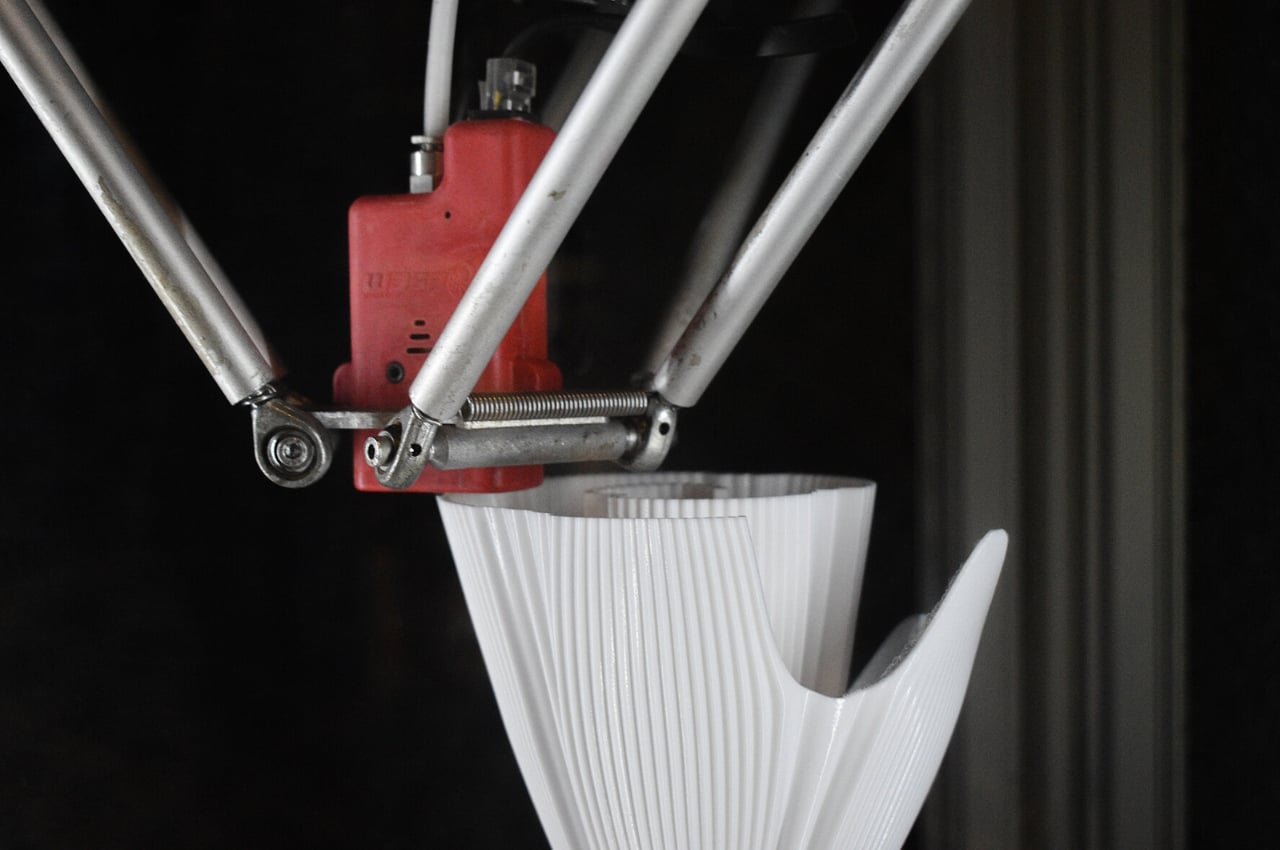

3D Printing is gaining more momentum and popularity than ever. Designers and architects all over the world are now adopting 3D Printing for the creation of almost all types of products and structures. It’s a technique that is being widely utilized in product design, owing to its simple and innovative nature. But designers aren’t employing 3D printing only to create basic models, they’re utilizing this technique in mind-blowing ways as well! From a 3D-printed terracotta cooler to 3D-printed footwear that pushes the limits of tech and design – the scope of this dependable technique is unlimited! Dive into this collection of humble yet groundbreaking 3D-printed designs.

1. Pure Plants

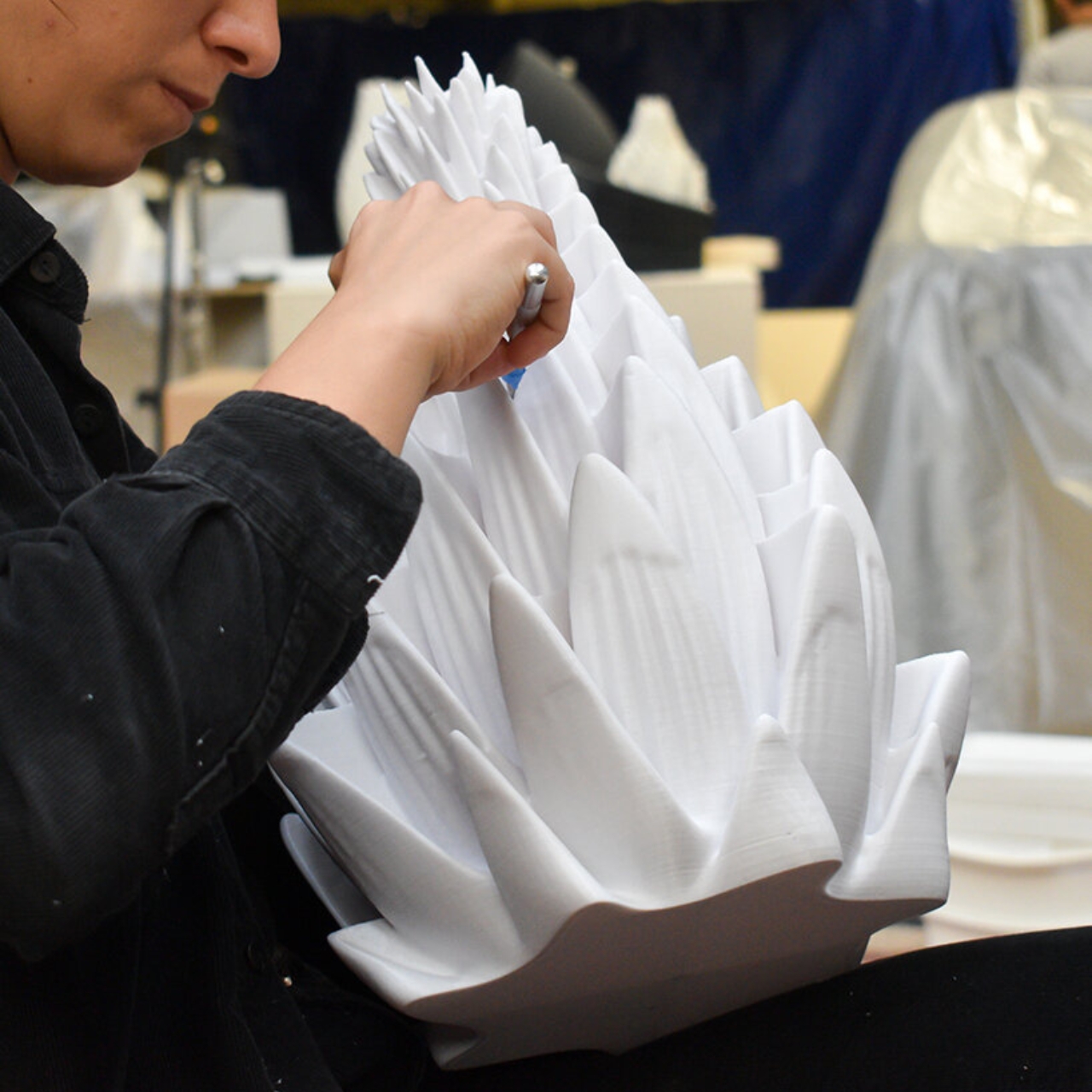

If you’re someone who tends to kill all the plants you adopt, then a Barcelona-based company has the perfect solution for you – Pure Plants. Pure Plants are 3D-printed plant-looking sculptures, that are much more than just decorative items for your living space.

Why is it noteworthy?

They actually use Pure.Tech technology to turn these “plants” into air purifiers that are able to absorb and neutralize carbon dioxide, nitrogen oxide, and other volatile organic compounds.

What we like

- Function as air purifiers to make the indoor air you breathe healthier

- The material used to create the living sculptures is also sustainable

What we dislike

- The average size of each 3D-printed plant is quite big, so its not easy to blend into every home decor

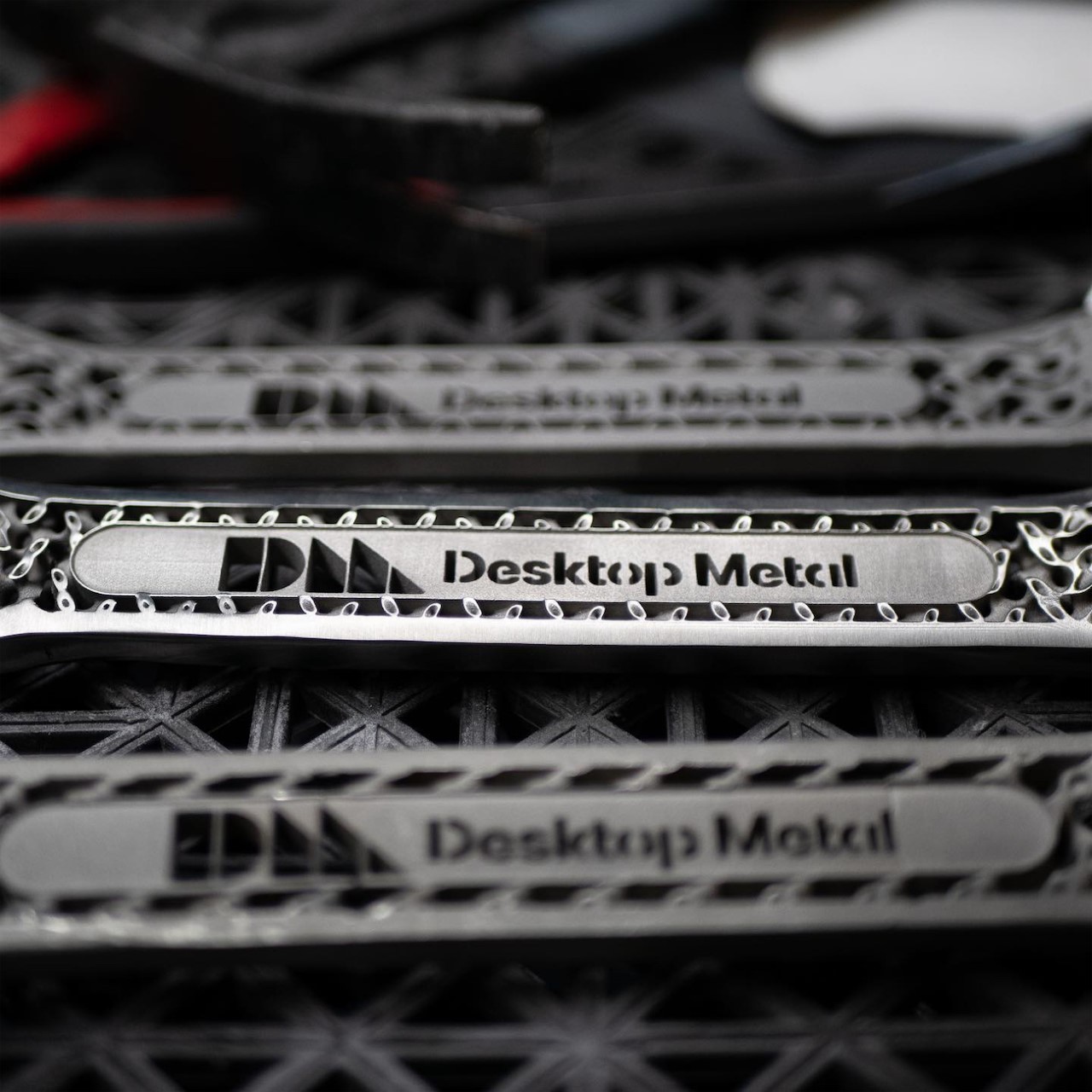

2. 3D-printed Wrench

Have a look at these unique tools from Desktop Metal, and you will instantly notice that is there something different about them. They arent like the typical die-cast wrenches with solid metal bodies that you see, these tools feature a textured inner surface with multiple holes and cavities.

Why is it noteworthy?

The inner surface of these wrenches uses a gyroid-style in-fill, commonly seen in 3D printing to fill up inner spaces with support material while conserving plastic. The gyroid inner mass gives these metal wrenches their strength while simultaneously cutting down on material and weight. The result is the same, functional tool but with nearly 30% less mass and weight.

What we like

- The various parts have a higher and more uniform density (up to 99%) than other metal 3D printing methods while being faster too

What we dislike

- The prototype wrench is less of an actual product and more of a showcase of Desktop Metal’s capabilities

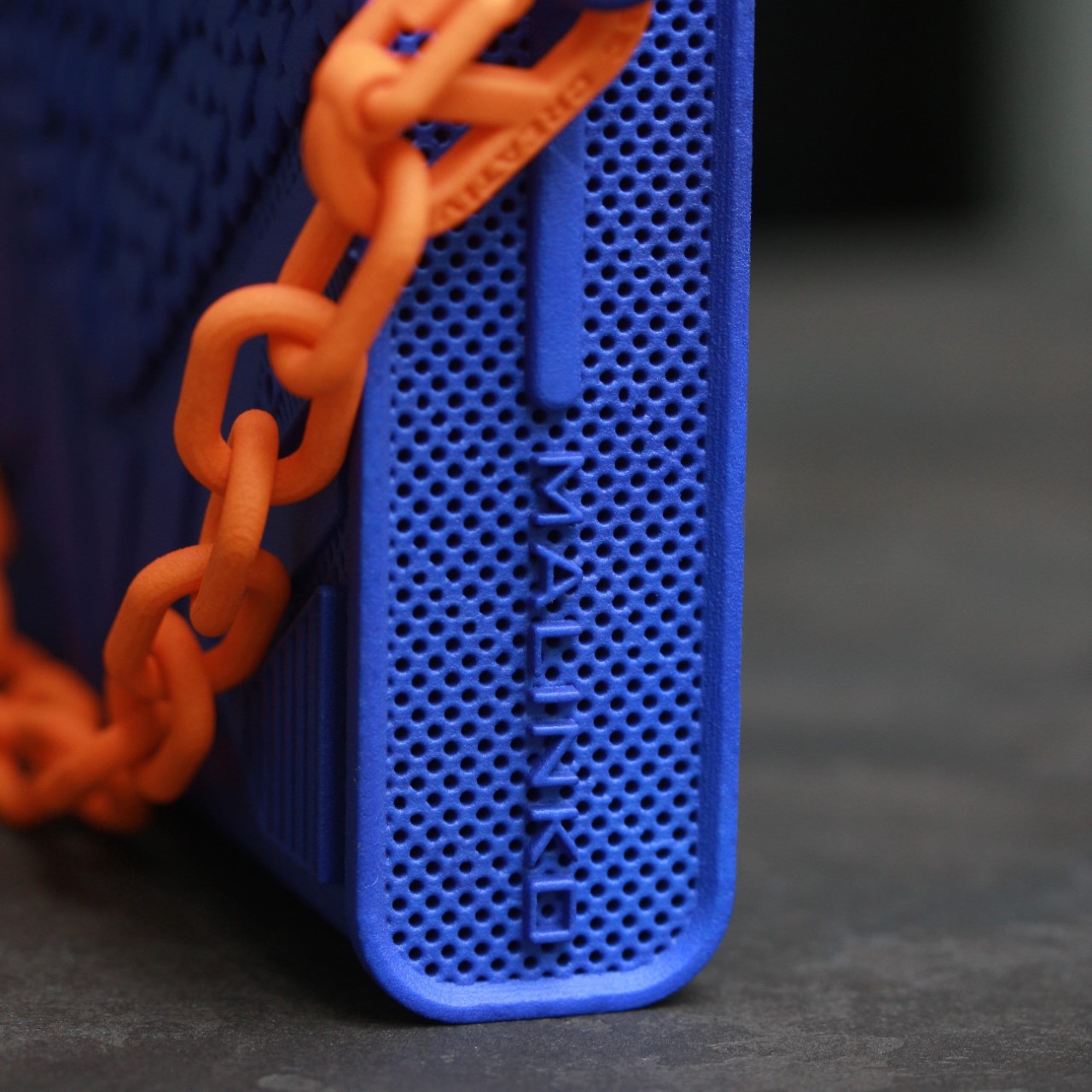

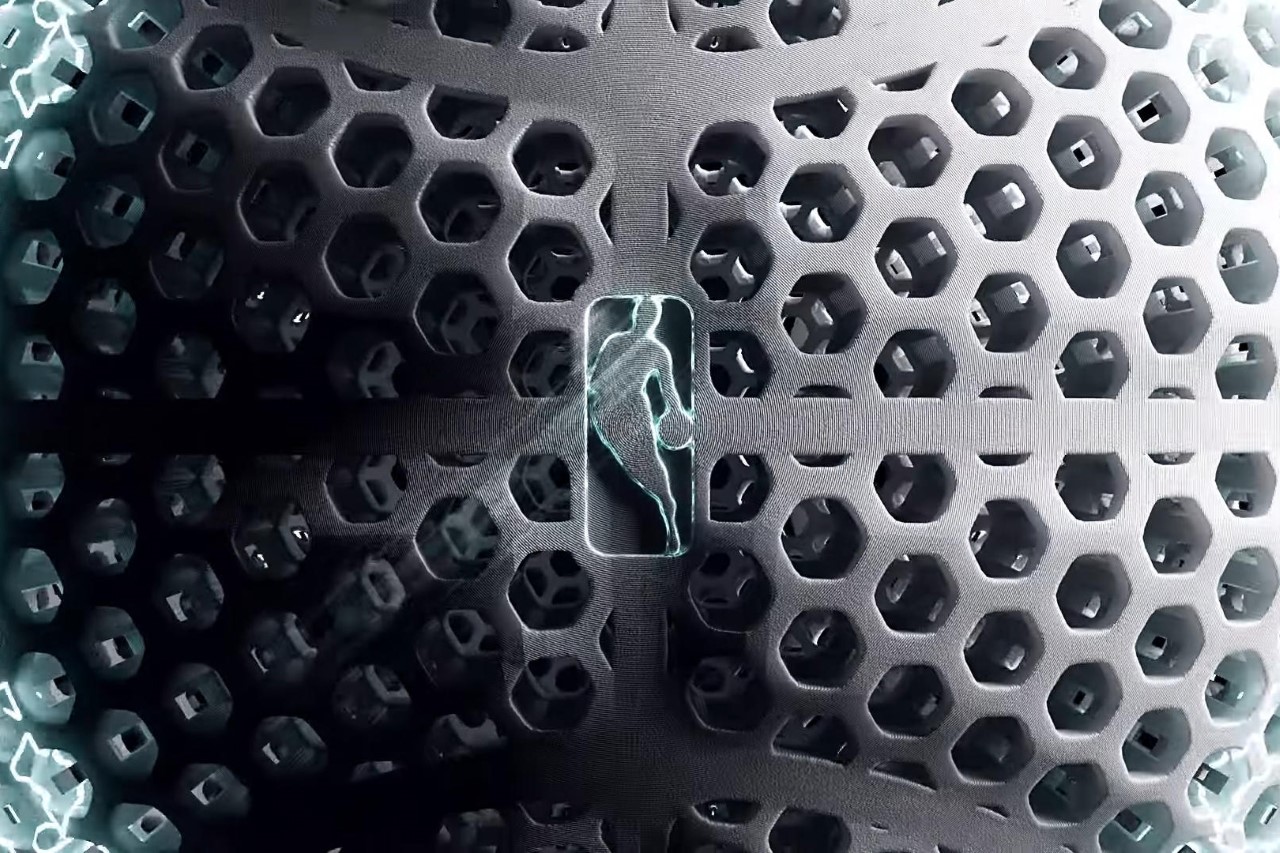

3. Wilson’s Airless Basketball

Wilson unveiled its latest airless basketball that utilizes a see-through 3D printed mesh similar to those airless car tire concepts we’ve seen before. This creates a ball that bounces just like a basketball, but doesn’t look like any basketball we’ve seen before!

Why is it noteworthy?

Created as an experimental prototype by Wilson Sporting Goods Co.’s R&D (Basketball) division, the Airless Basketball prototype is a stunning piece of design and engineering that looks, weighs, and bounces just like a basketball, but fundamentally rethinks the ball’s physical structure and underlying physics.

What we like

- Utilizes a 3D hexagonal mesh structure that is highly elastic, allowing it to bounce just like a pressurized ball

- Doesn’t need pumping for refilling

What we dislike

- The ball’s lifespan, resistance to damage, how well players can grip it, whether objects can get stuck inside the mesh, and the overall dynamics of the ball are still undetermined

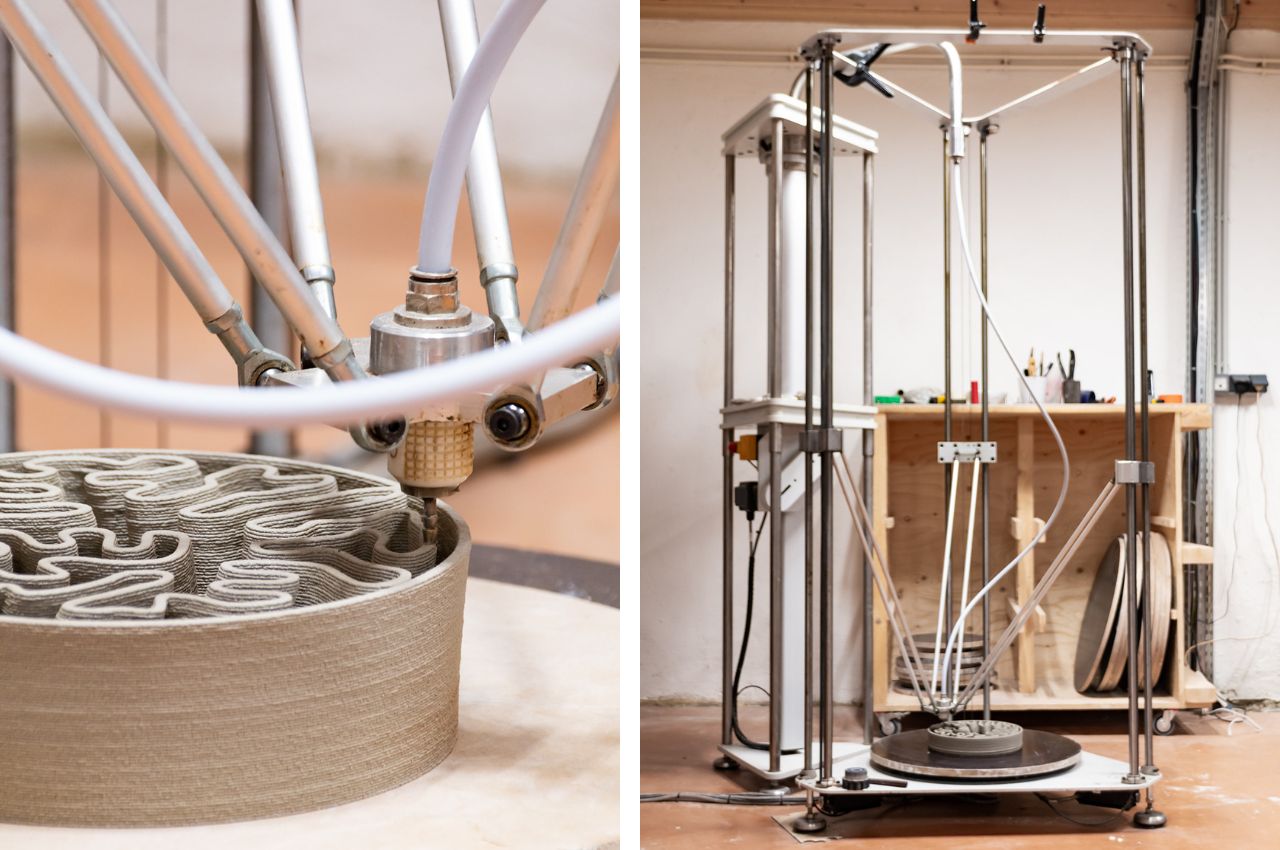

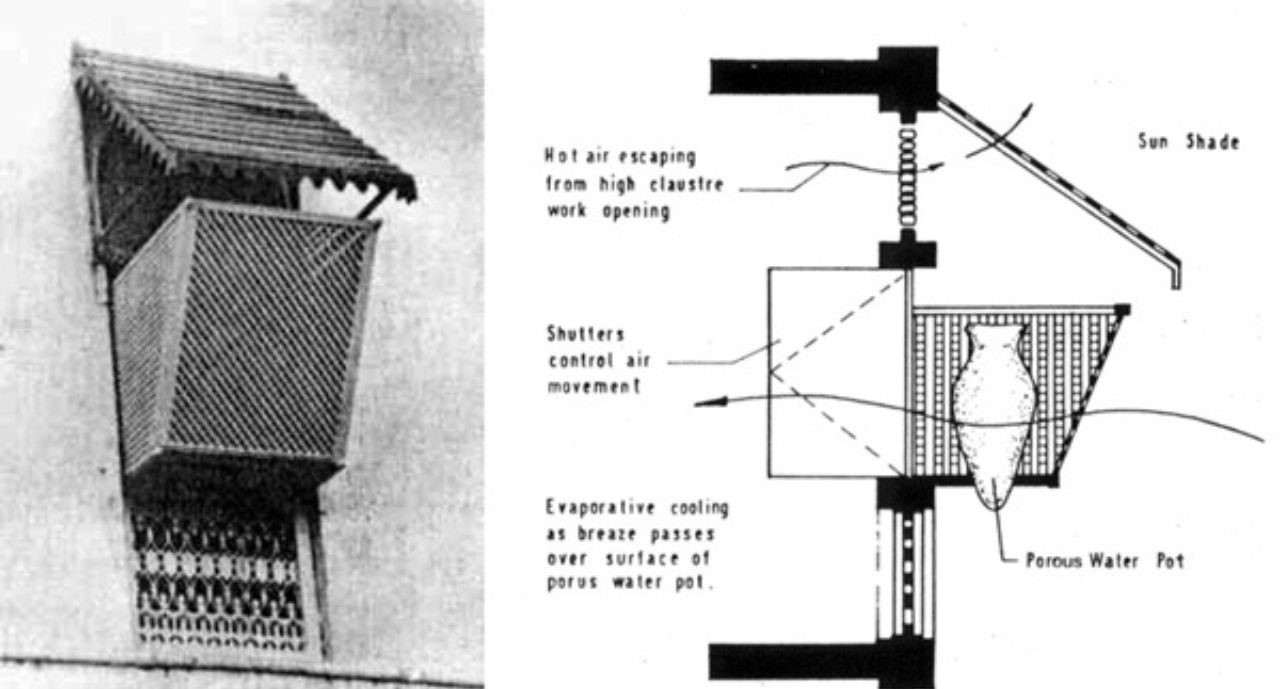

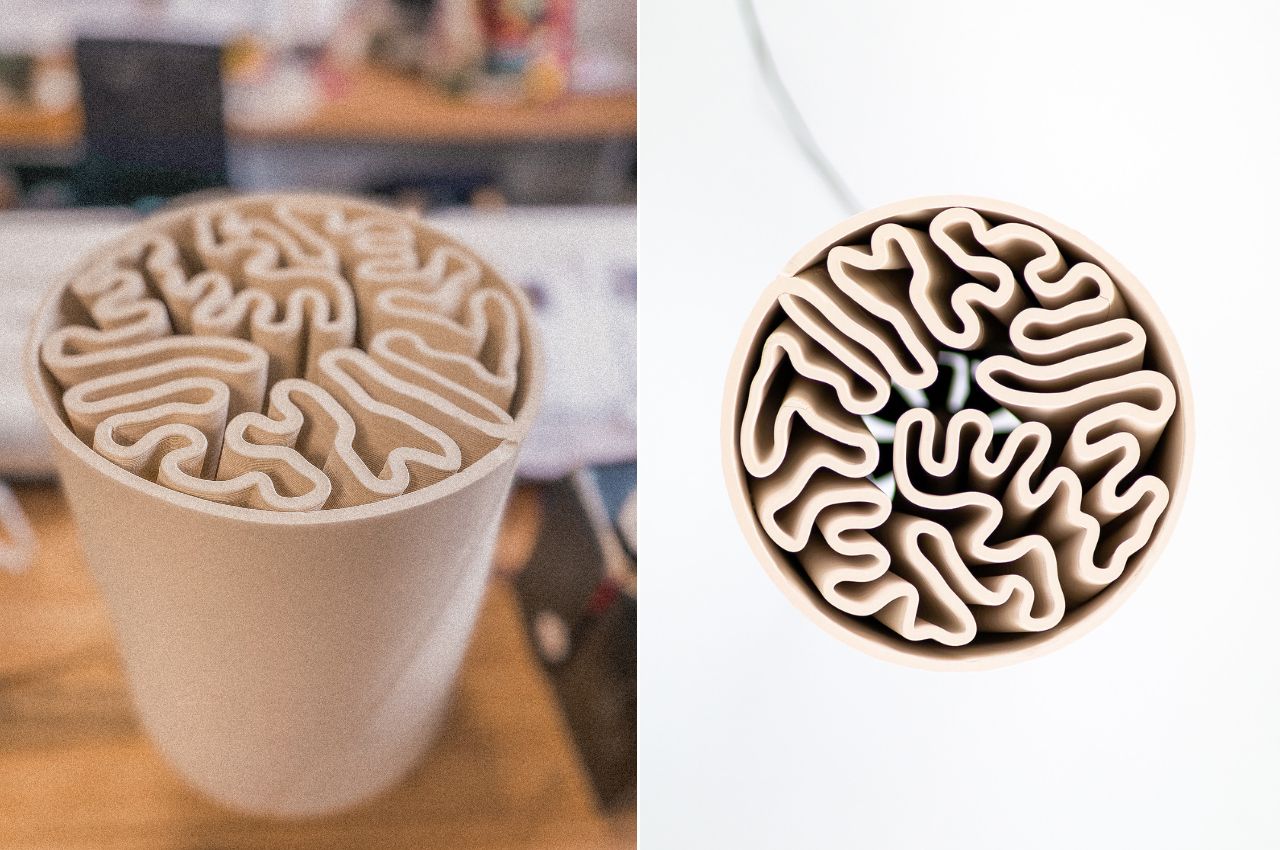

4. Terracotta Cooler

This low-tech terracotta cooler is a promising and sustainable cooling solution, that was created as a result of the collaborative efforts between visionary designers and engineers.

Why is it noteworthy?

The low-tech cooler’s functionality is based on a well-engineered ventilation system which is known as the Water Evaporative Evaporator Effect (WEEE), which allows the airflow to come into contact with the wet surface of the terracotta container, wherein the water undergoes a natural evaporation process, creating a refreshing flow of cold air.

What we like

- Showcases the power of nature-inspired solutions in addressing modern challenges

- Eco-friendly design

What we dislike

- The design is still being designed, so we cannot speak to the effective cooling capabilities of the design.

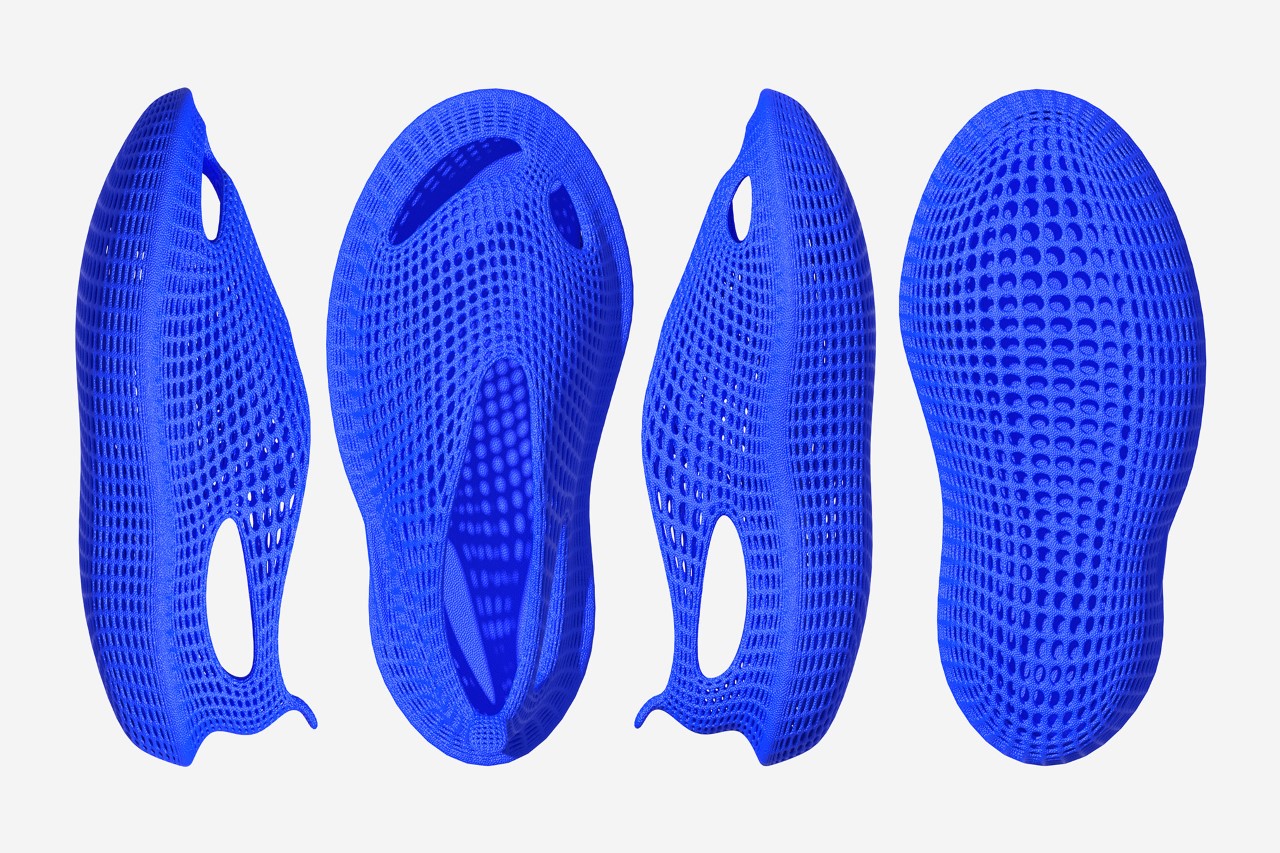

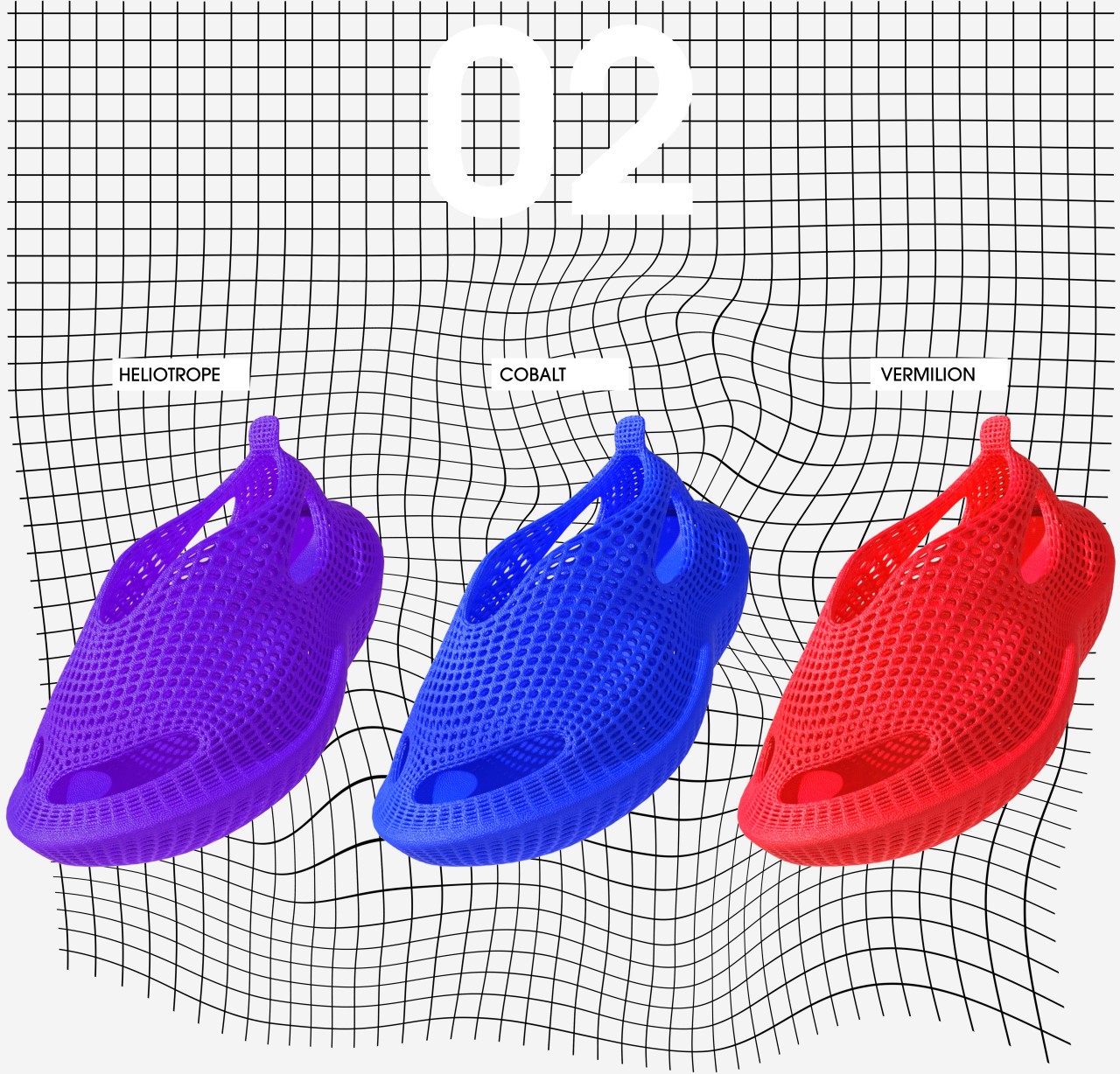

5. The EXPLR 02

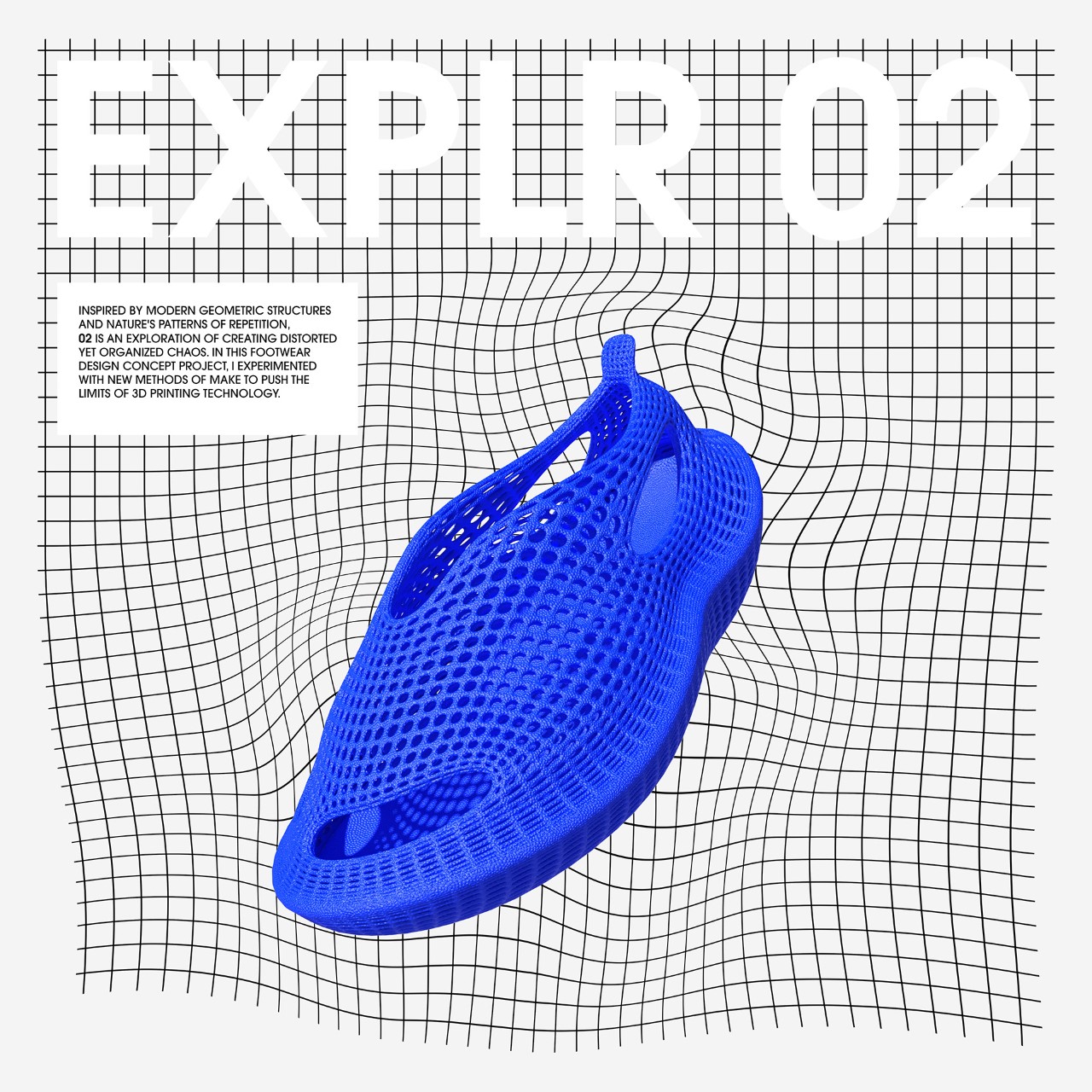

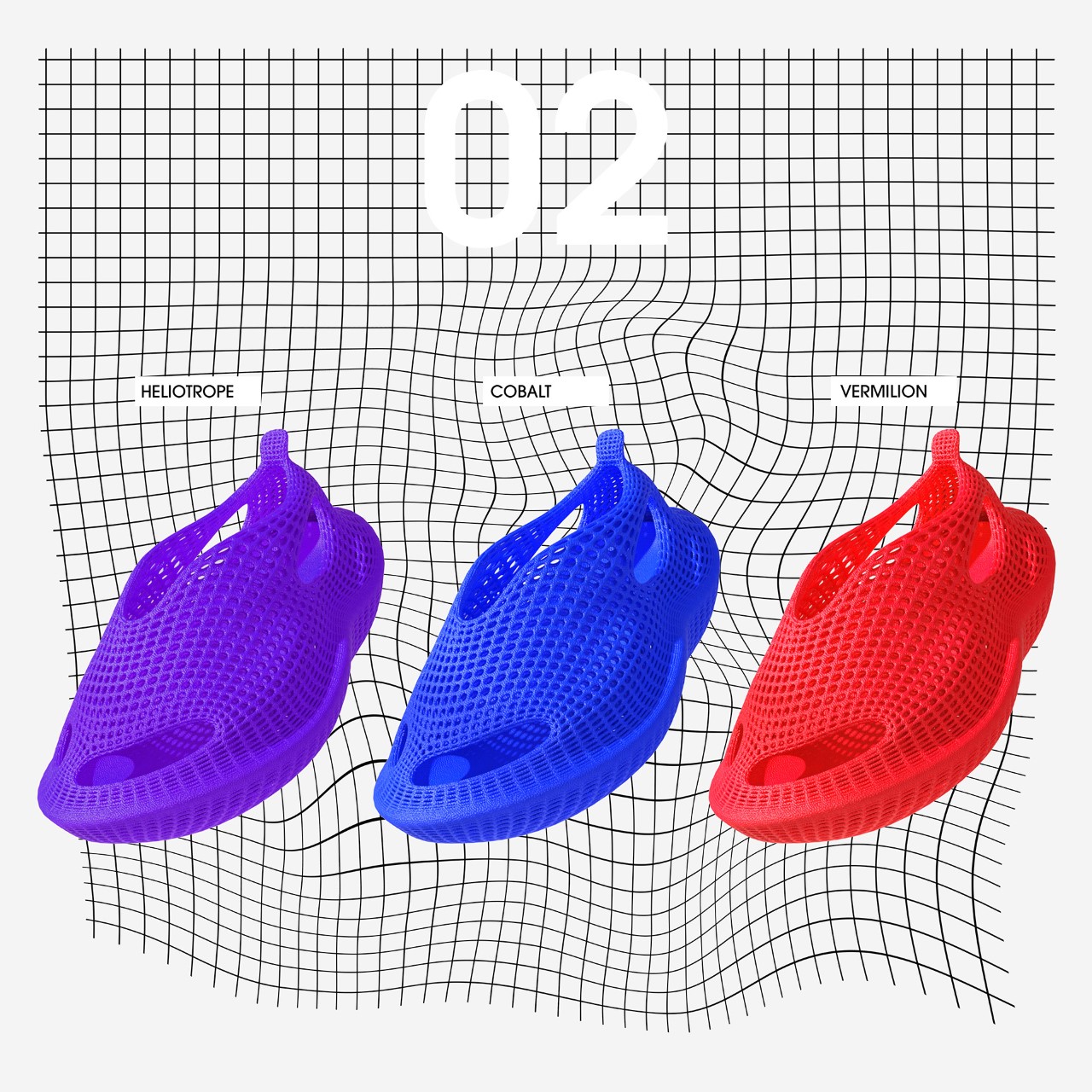

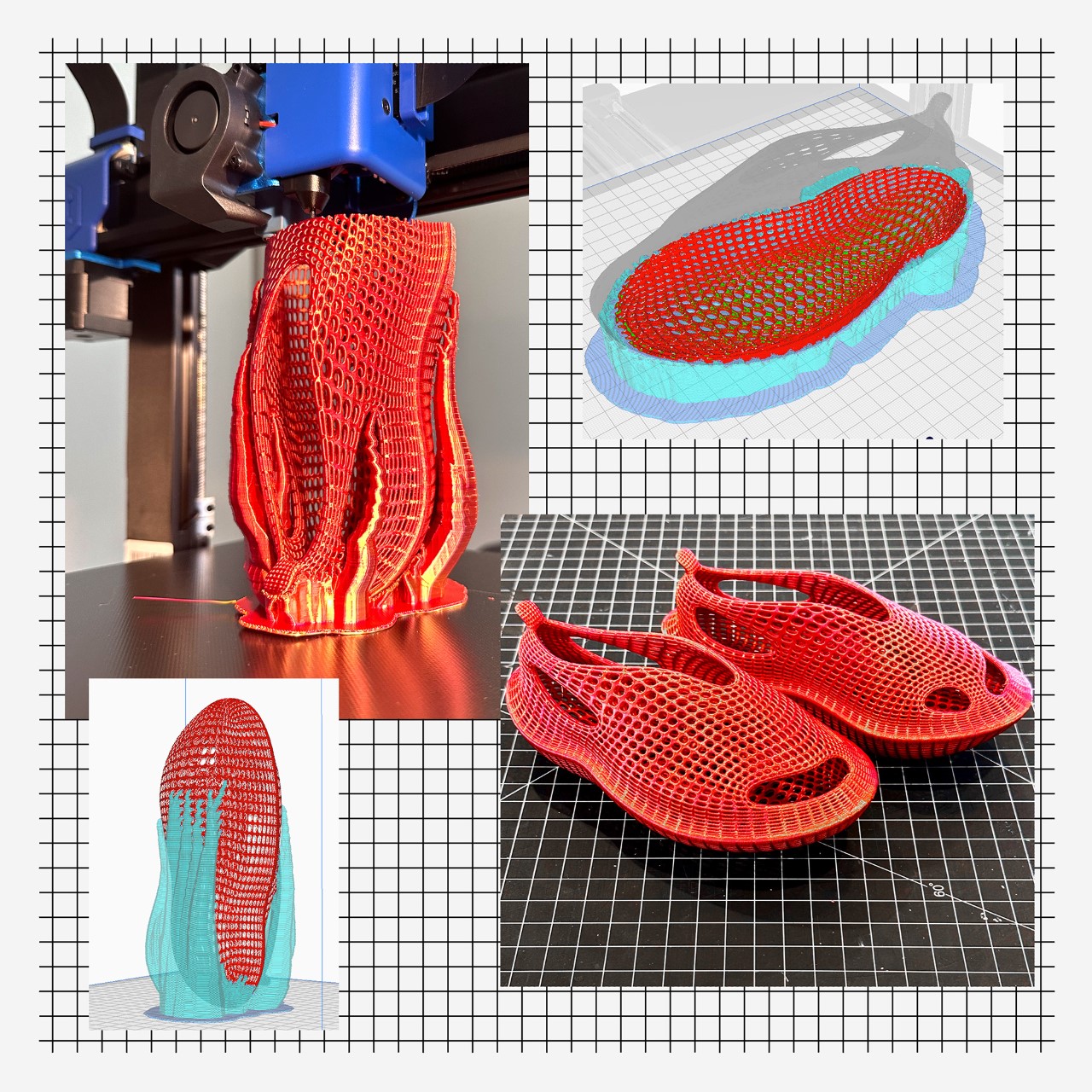

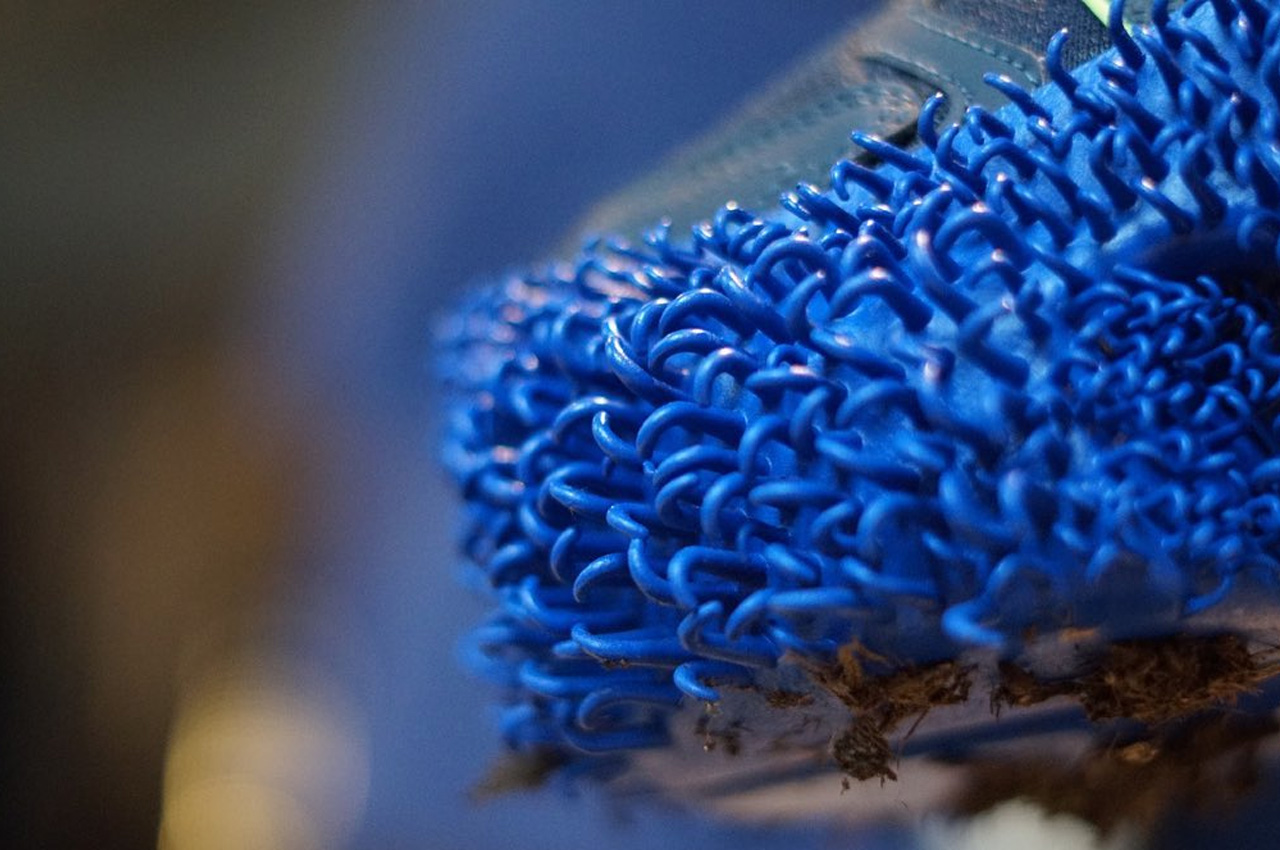

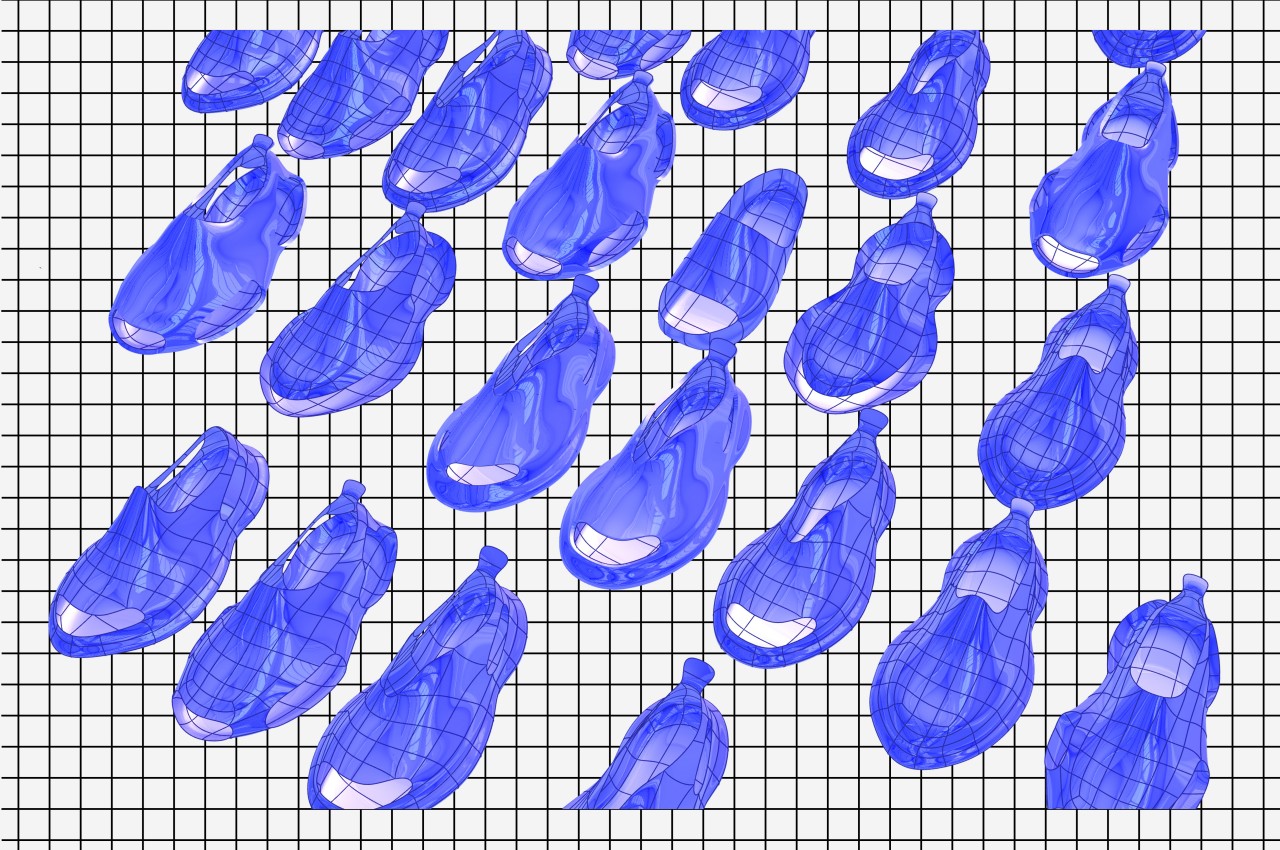

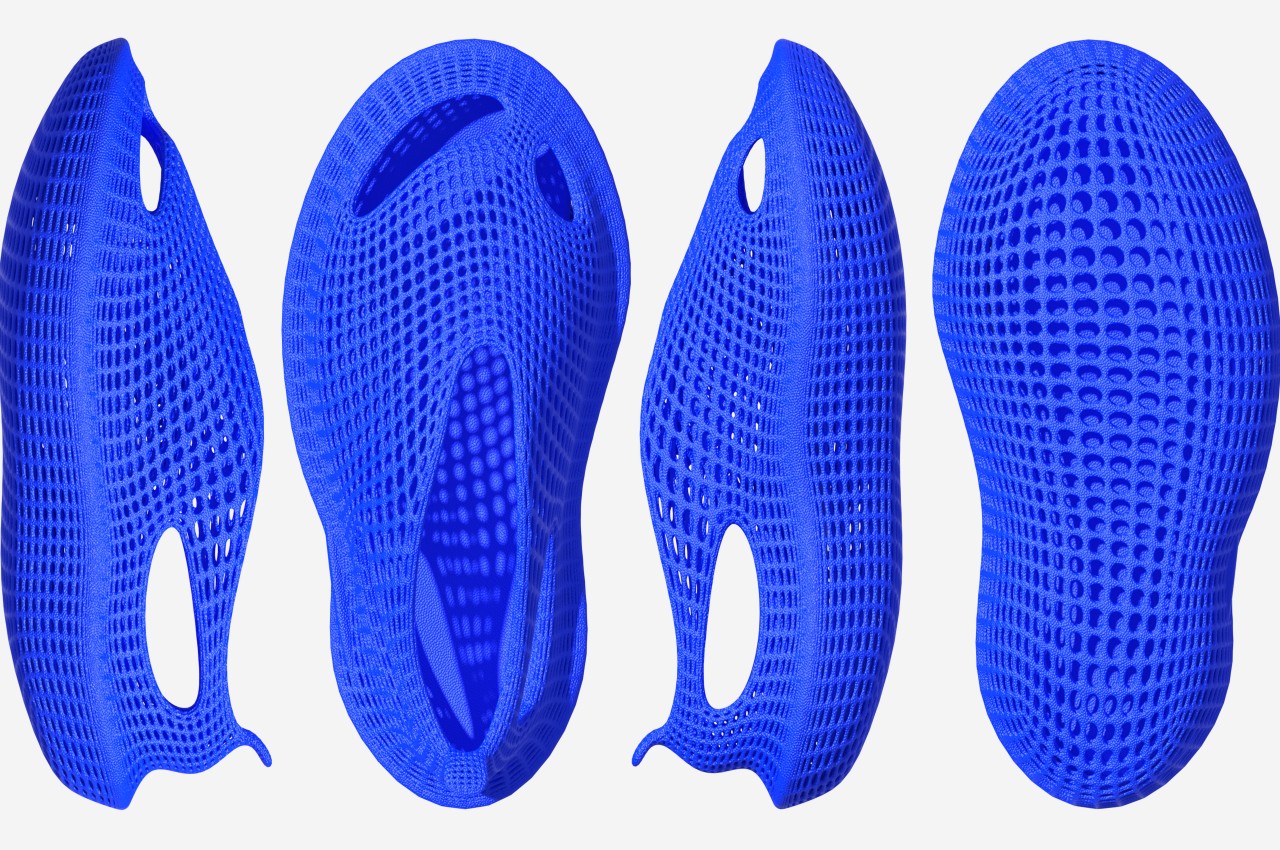

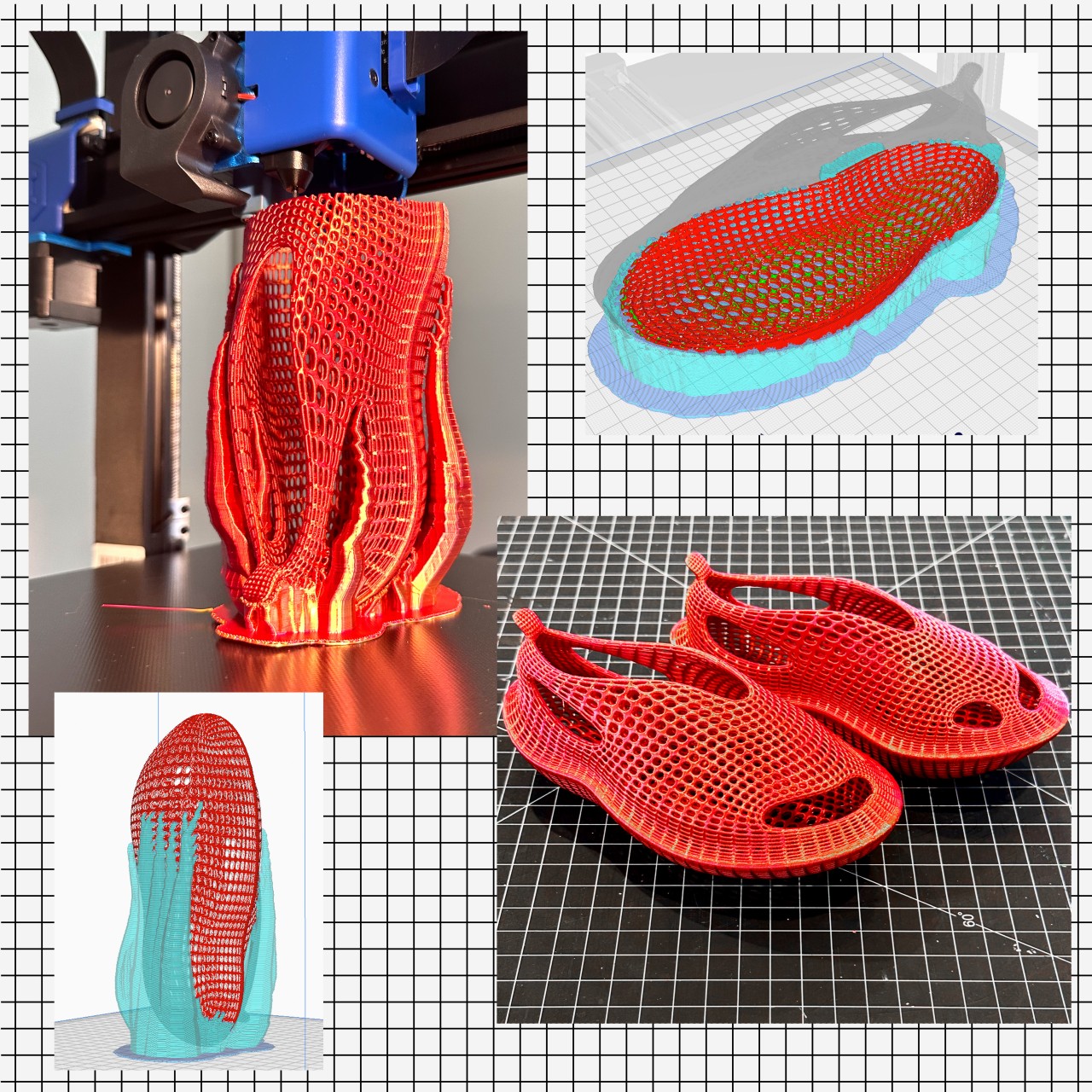

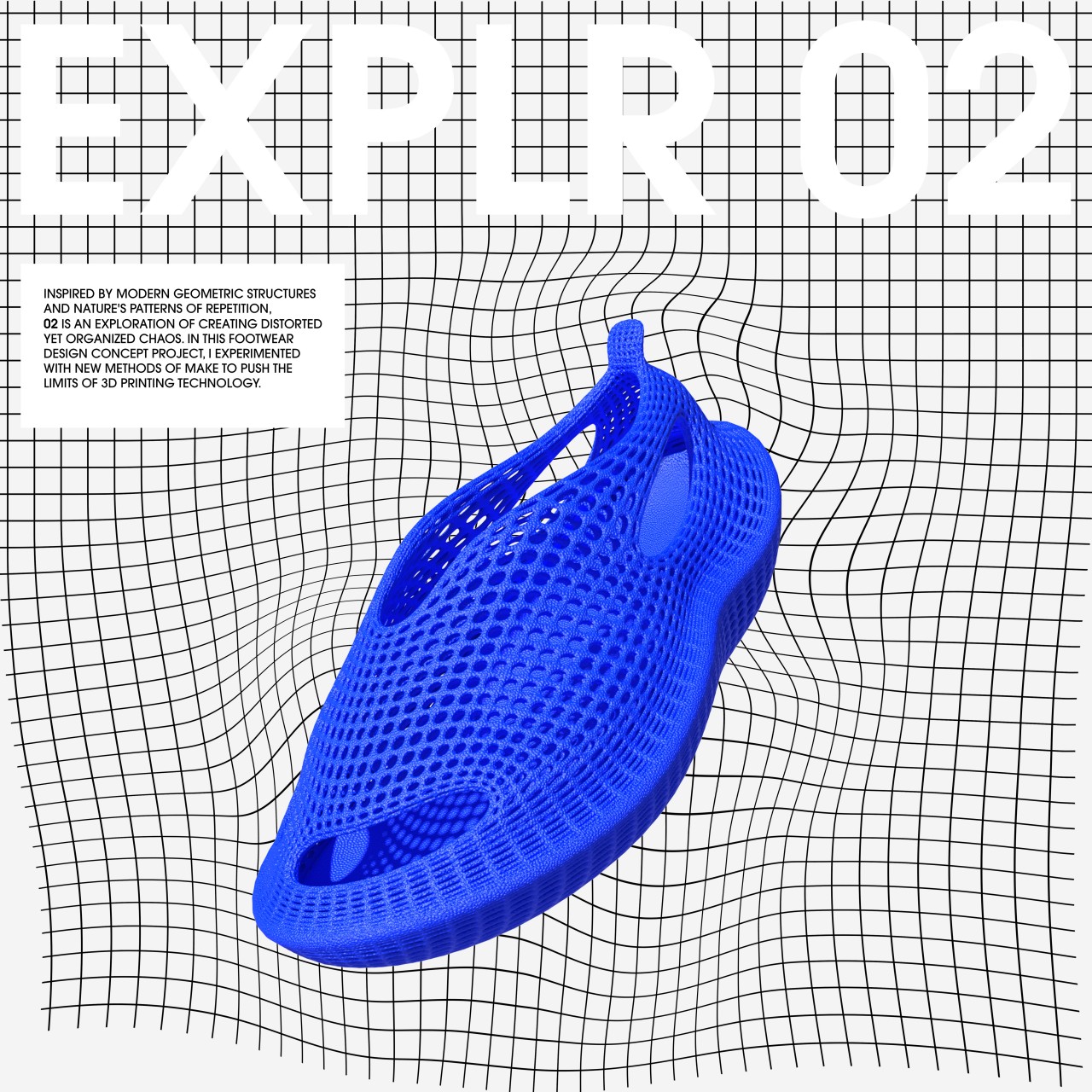

Matthew Blunt designed the EXPLR 02 – a pair of shoes that look like the wireframe you see in 3D modeling software, although it has an even higher resolution and a number of empty spaces.

Why is it noteworthy?

The design takes inspiration from the nature of those digital artifacts. Repeating patterns, organic forms, and an almost chaotic composition all come together to create footwear that is both beautiful and intriguing.

What we like

- Useful + practical footwear design

What we dislike

- The structural integrity of such a design can also be in question since the thin intersecting lines could make it less durable under rugged conditions

6. The Paris Bookend

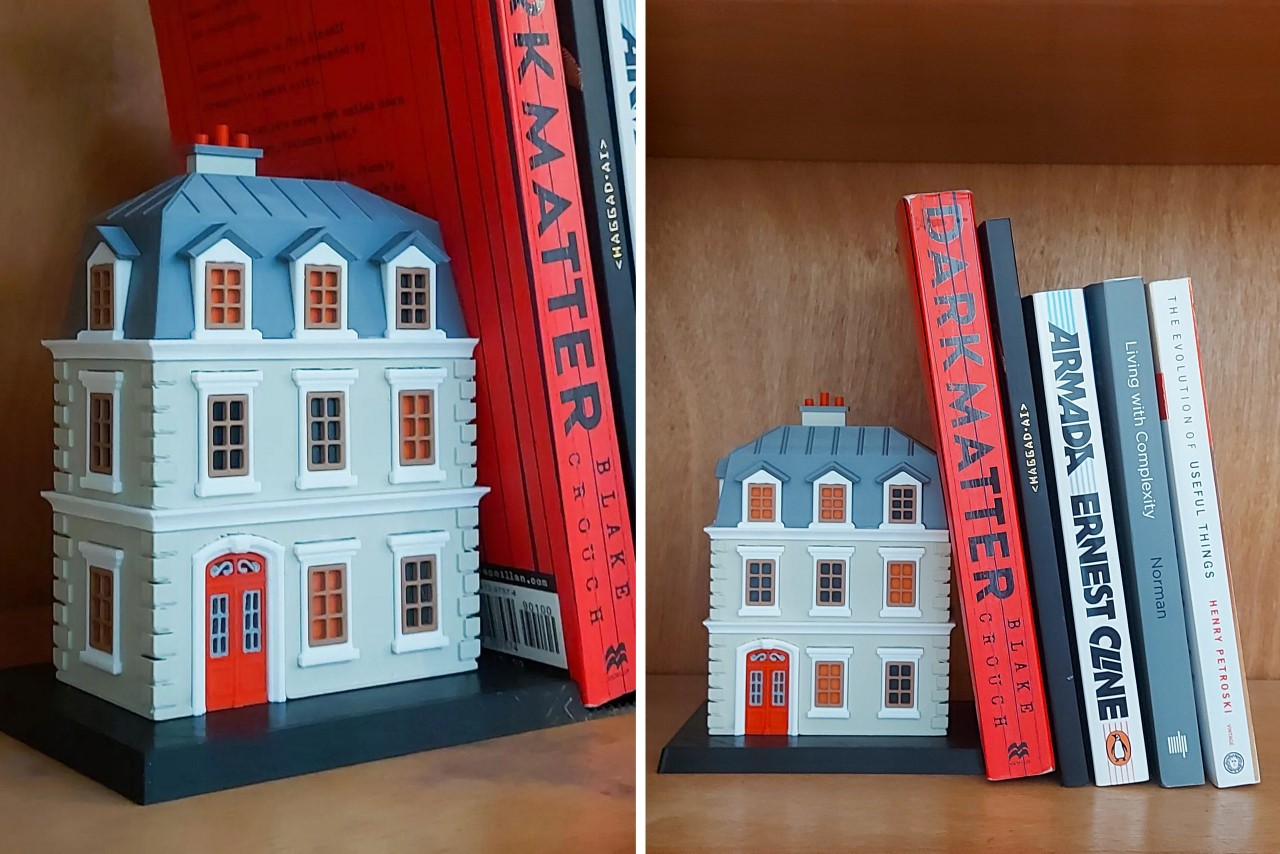

Designed to add an adorable French charm to your bookshelf, the Paris Bookend is a miniature 3-story building that is created in the classic Hausmanns style. The adorable home features a Mansard roof, that lets your books naturally lean over against the side of the mini building.

Why is it noteworthy?

It comes with detailed out chimneys, windows, and an adorable red door too, adding a gorgeous Parisian charm to your home that feels a lot more authentic than those run-of-the-mill Eiffel Tower memorabilia.

What we like

- Adorable + functional solution to store your books

What we dislike

- If you don’t print the base platform with high infills, the building could collapse on itself

7. 3D Printed Lamborghini Aventador

Did you know that you can now download a car?! Sterling Backus, an enthusiastic father and physicist downloaded and 3D printed an entire Lamborghini Aventador.

Why is it noteworthy?

Sterling started by first downloading a 1:10 scale model of the Aventador, scaling it up, separating the parts, and even adding a few signature modifications of his own, like making the car’s body wider.

What we like

- Significantly lighter than the original car

- The entire car is built from scratch

What we dislike

- The overall build still needs some work, and the car still needs a Red, White, and Black paint job once everything’s ready

8. Cozy Cleo Lamp

Based in Germany, the design studio EveryOtherDay designed this 3D-printed table lamp. It was created using recycled plastic bottles and cardboard. This sustainable product is a fine specimen of circular design and wholly embodies minimalistic design principles.

Why is it noteworthy?

The table lamp is Rasenberger’s innovative attempt to tackle the excessive wastage of cardboard, and instead incorporate it in a circular design process, providing the material with a new and redefined identity. In this entire process, almost 200g of cardboard, and 10 plastic bottles are recycled.

What we like

- Once the lifecycle of the lamp has ended, it can be recycled, allowing the materials to once again be utilized in a completely new and different manner

What we dislike

- Not sure if the lamp will have a long lifespan

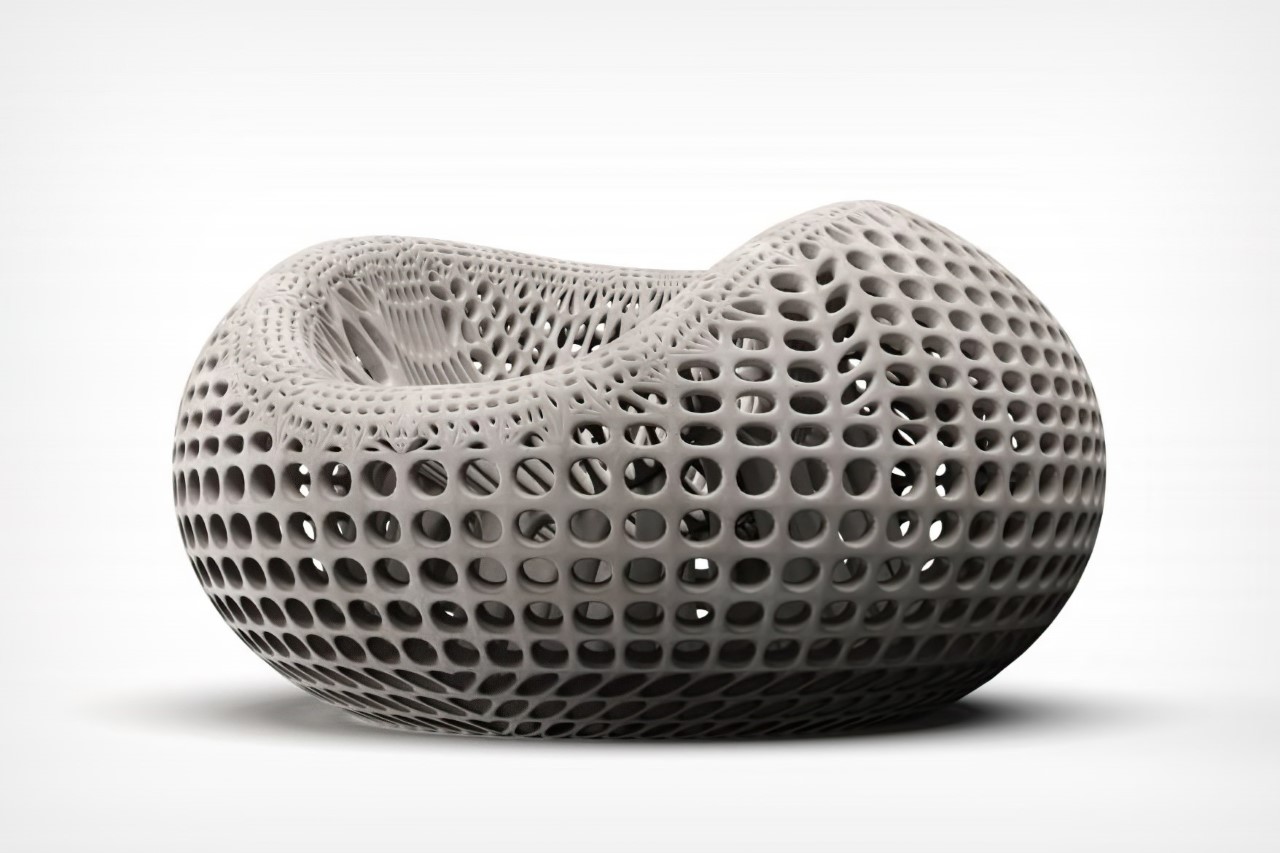

9. The Throne

Designed by Spanish design studio Nagami and To: this 3D-printed toilet is called The Throne and is made up of three parts – a teardrop-shaped body, a double-curved sliding door, and a bucket for solid waste.

Why is it noteworthy?

The various parts of the toilet were printed within three days – pretty quickly! This includes the base and multiple other smaller accessories that were either injection molded or ordered. It also includes an off-the-shelf separation toilet seat to separate urine from solids for composting.

What we like

- Goes further in its realization of a circular economy by composting the waste produced by users and using this compost locally

What we dislike

- The cost of production needs to be dropped

10. Wabo

Called Wabo, this collection of hand boards is created from plastic waste that is produced using 3D-printed prototyping. Wabo is an excellent initiative to make something out of plastic waste, that is actually functional and can be used!

Why is it noteworthy?

Uido Design is a studio known for its catalog of 3D printable product designs and its team is doing something about the waste they produce during the design process. Shredding the plastic waste produced from 3D printing into bits and pieces, Uido Design uses the waste to create hand boards for users to ride the ocean waves.

What we like

- The hand boards are handcrafted

What we dislike

- Not a necessary product, but still fun!

The post Top 10 3D Printed Designs That Are Pushing The Limits Of Sustainable Design & Tech first appeared on Yanko Design.