Ant Studio’s Beehive is a pioneering solution that marries traditional cooling techniques with modern design to offer an eco-friendly alternative to energy-intensive cooling and air purification systems. Created by Monish Kumar Siripurapu, a New Delhi-based architect and founder of Ant Studio, the Beehive system exemplifies the firm’s commitment to integrating art, architecture, technology, and nature. As the country sees soaring temperatures this summer, with New Delhi recording temperatures as high as the 50s Celcius (over 122°F), the Beehive is offering a low-cost tradition-backed cooling system that uses properties of materials and physics to help provide cooler temperatures without electricity or coolants.

Designer: Ant Studio

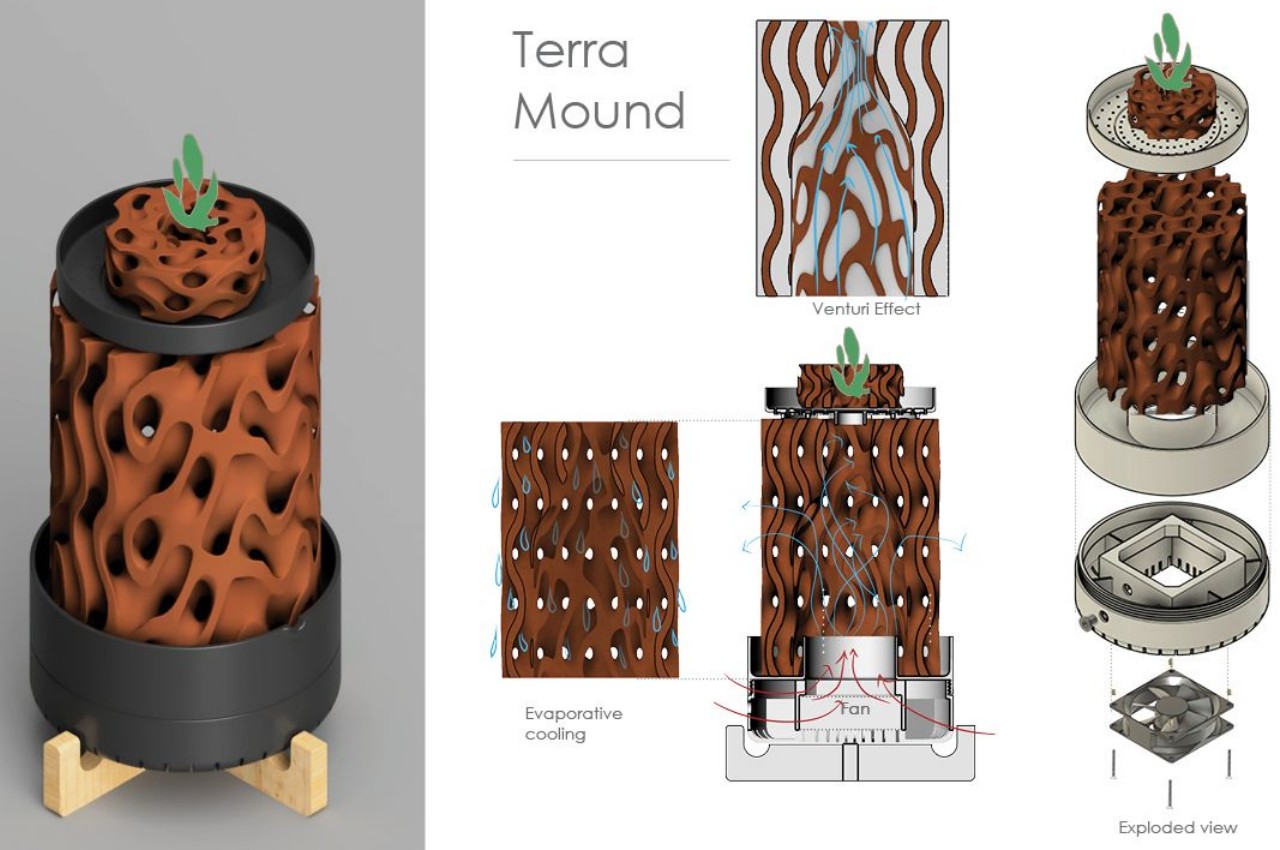

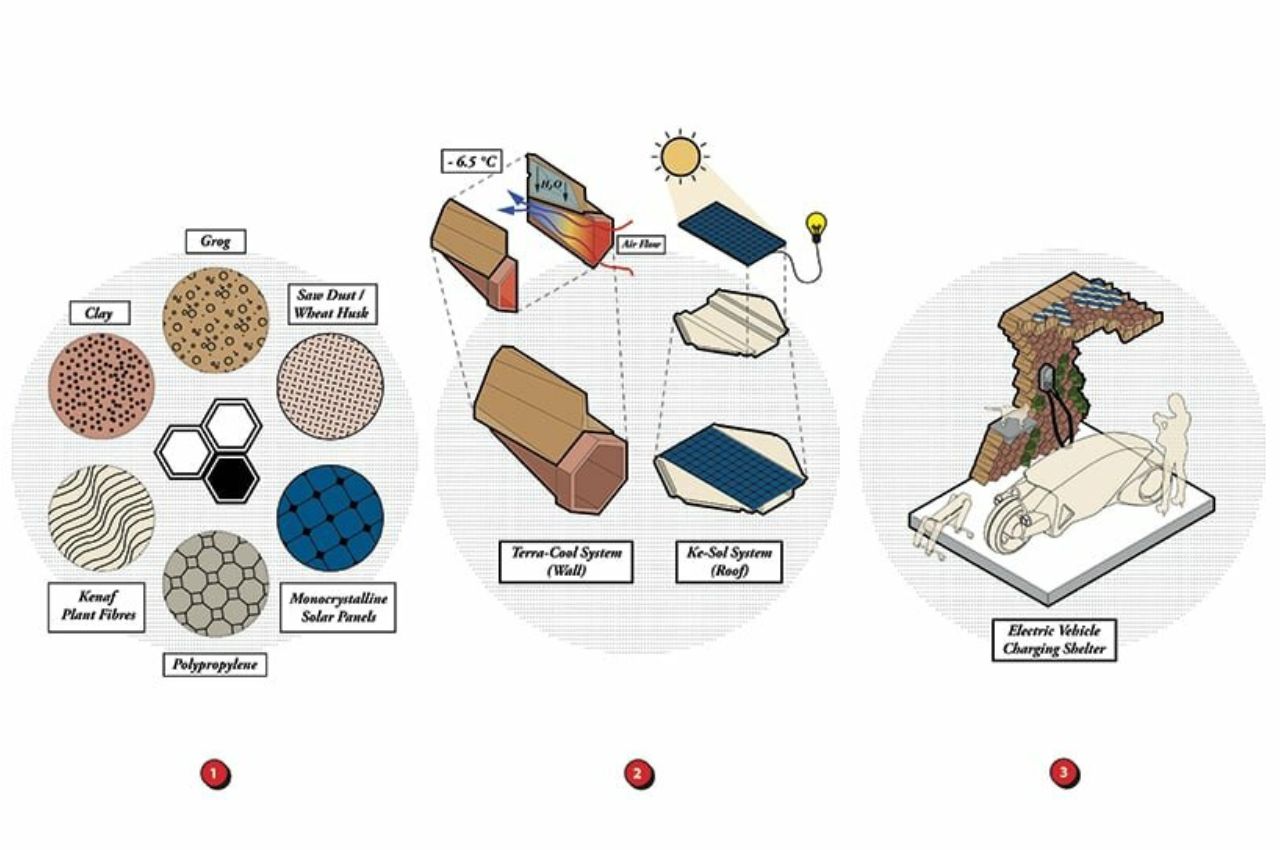

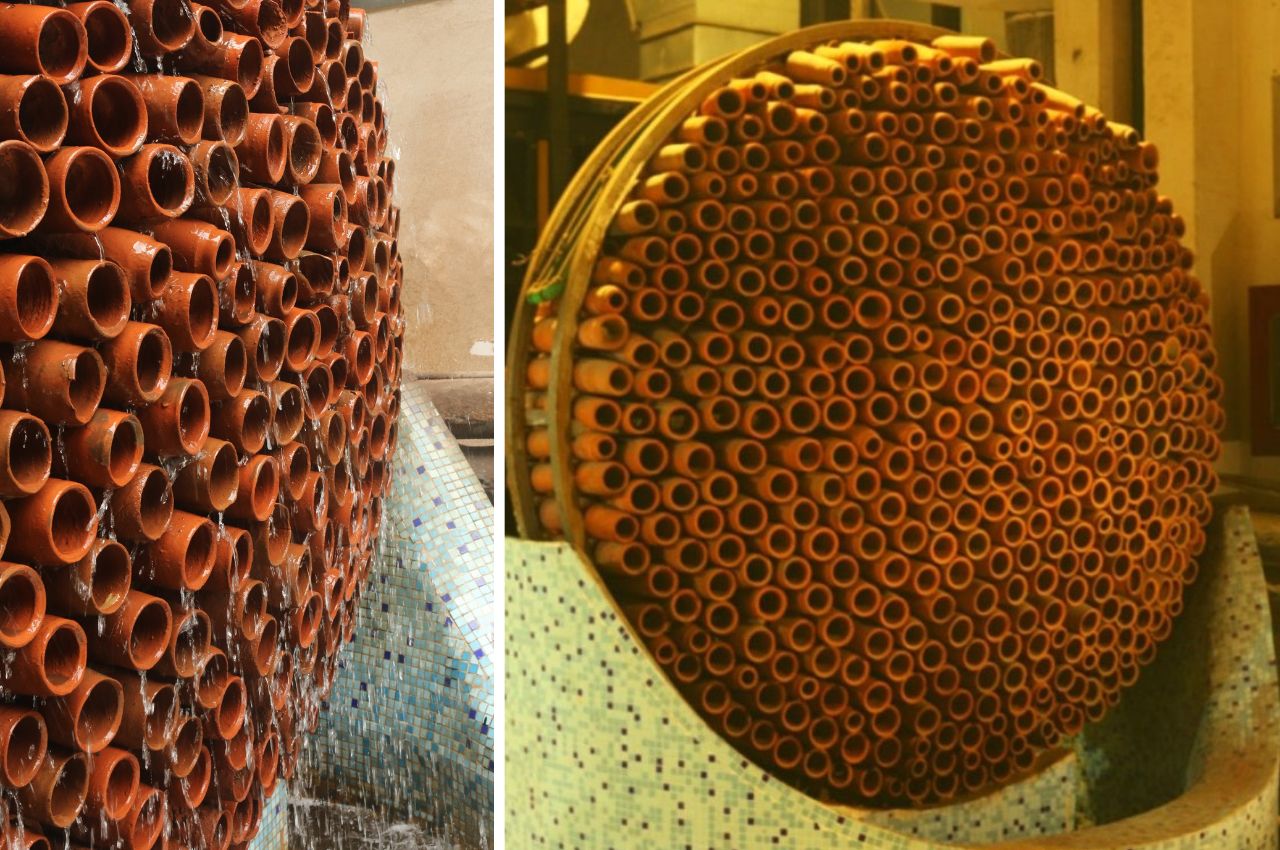

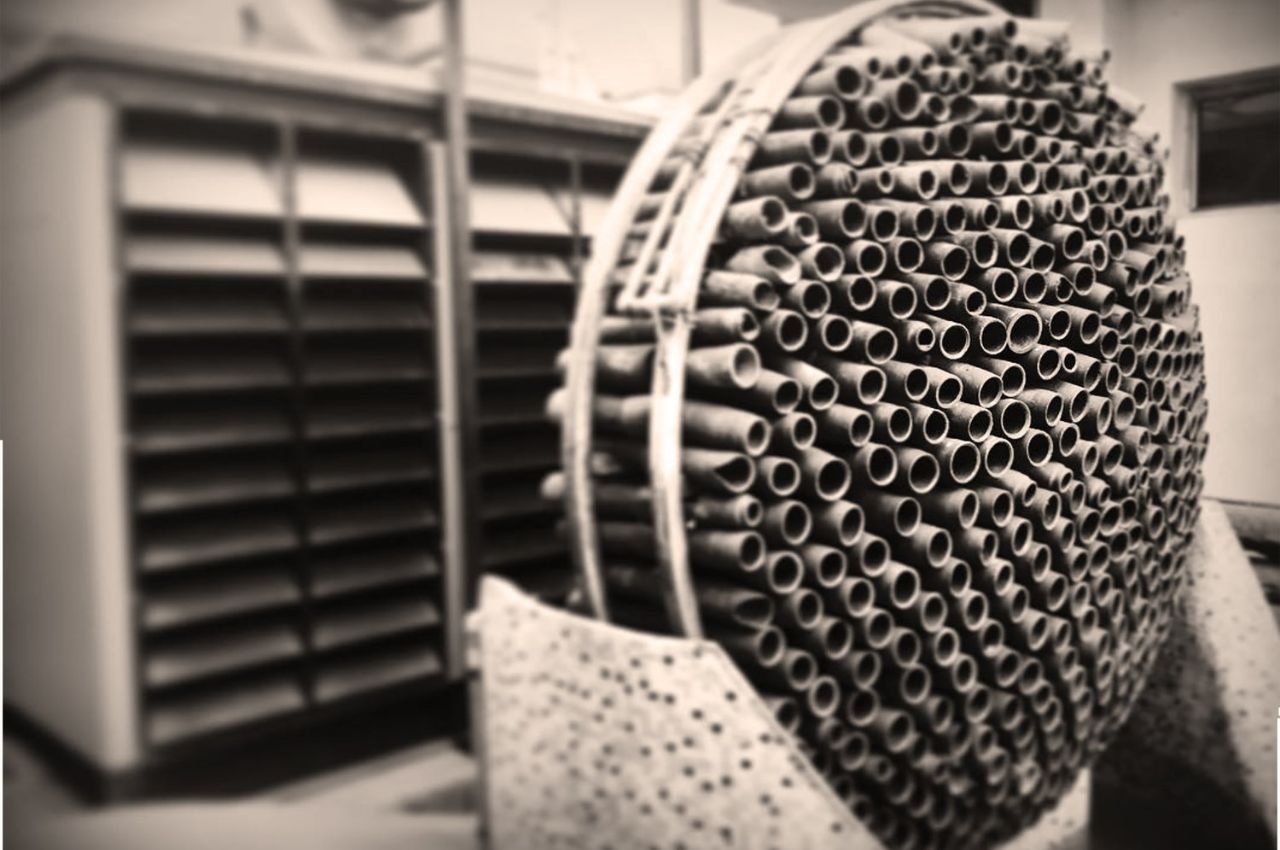

The Beehive system operates on the principle of evaporative cooling, a technique that has been utilized for centuries. The system employs earthenware pots, which are soaked with water to create a cooling effect as the water evaporates. This natural process is enhanced by the formation of biofilm on the pots, which aids in air purification. The Beehive’s modular design is not only zero-plastic and zero-emission but also aesthetically pleasing, making it an ideal solution for outdoor working conditions in urban environments.

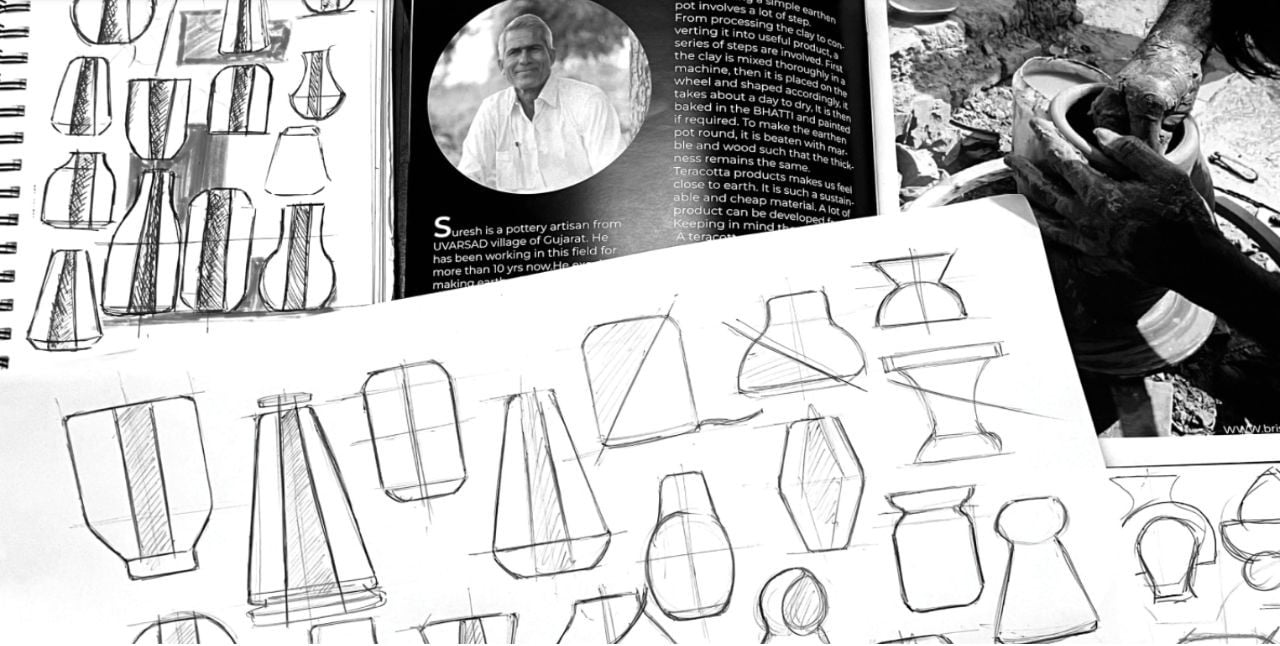

Earthen pots have long been recognized for their cooling properties. Egyptians fanned the porous jar of water to get cool air. The Romans on a similar concept, hung wet thick material on the doors of their houses or tents. Others, who were wealthy, constructed an artificial channel conveying water along the walls of their houses to reduce the temperature under extreme hot weather. These ideas from the past were analyzed and later assimilated and are now being adapted to contemporary needs, demonstrating the enduring value and sustainability of traditional practices. The Beehive project embodies this philosophy, merging the cultural and environmental benefits of traditional methods with modern design and technology.

What sets the Beehive apart is its zero-plastic and zero-emission design. The use of earthen pots is deeply rooted in Indian culture, where such pots have been used for centuries to keep water cool, making the craft easily available and recognized in India. This ancient wisdom is ingeniously adapted into a contemporary design that is both sustainable and aesthetically pleasing. The Beehive demonstrates how age-old techniques can be revitalized to address modern environmental challenges.

In addition to its environmental benefits, the Beehive project aims to revive the dying craft of pottery. By engaging local artisans to construct the terracotta cones, Ant Studio is generating employment opportunities and supporting traditional craftsmanship. This approach not only ensures the creation of high-quality components for the Beehive system but also contributes to the preservation of cultural heritage and the economic well-being of local communities.

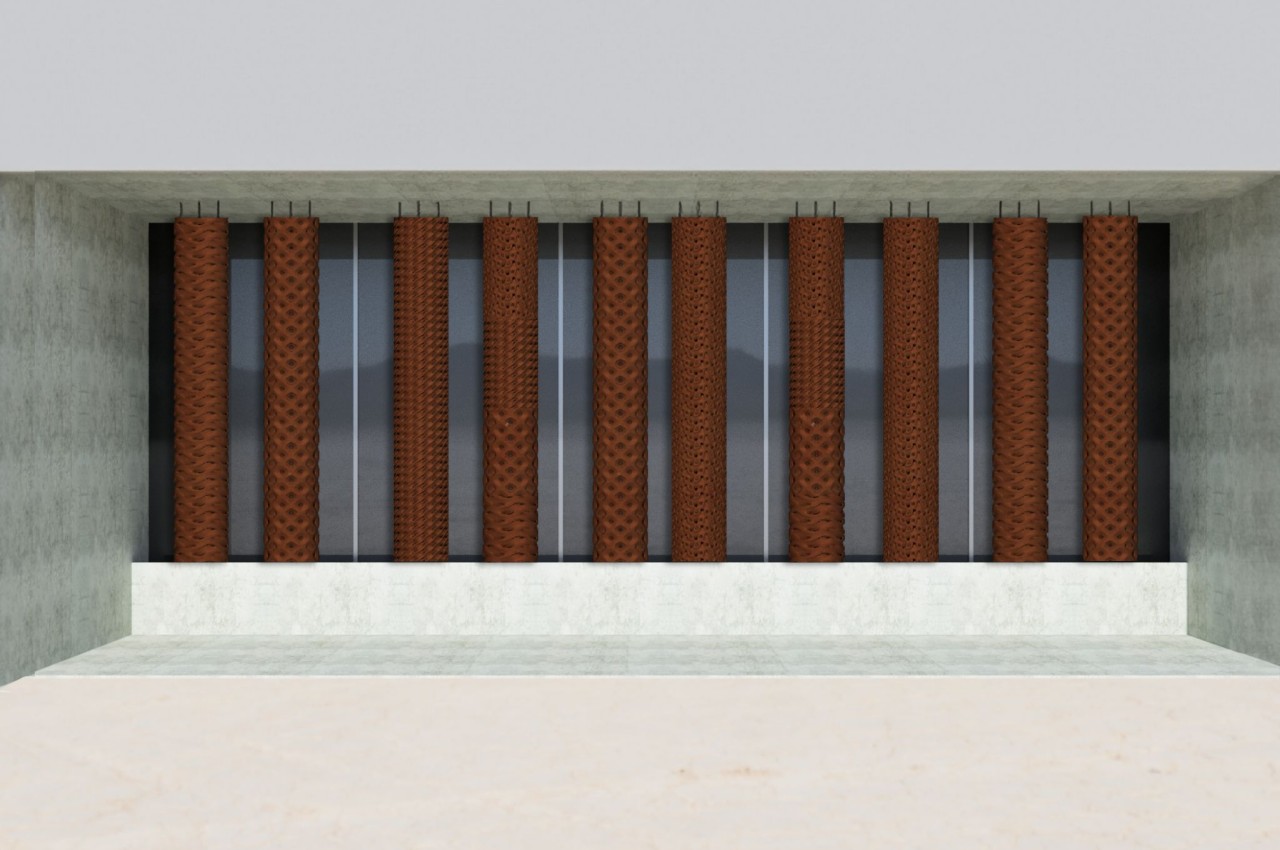

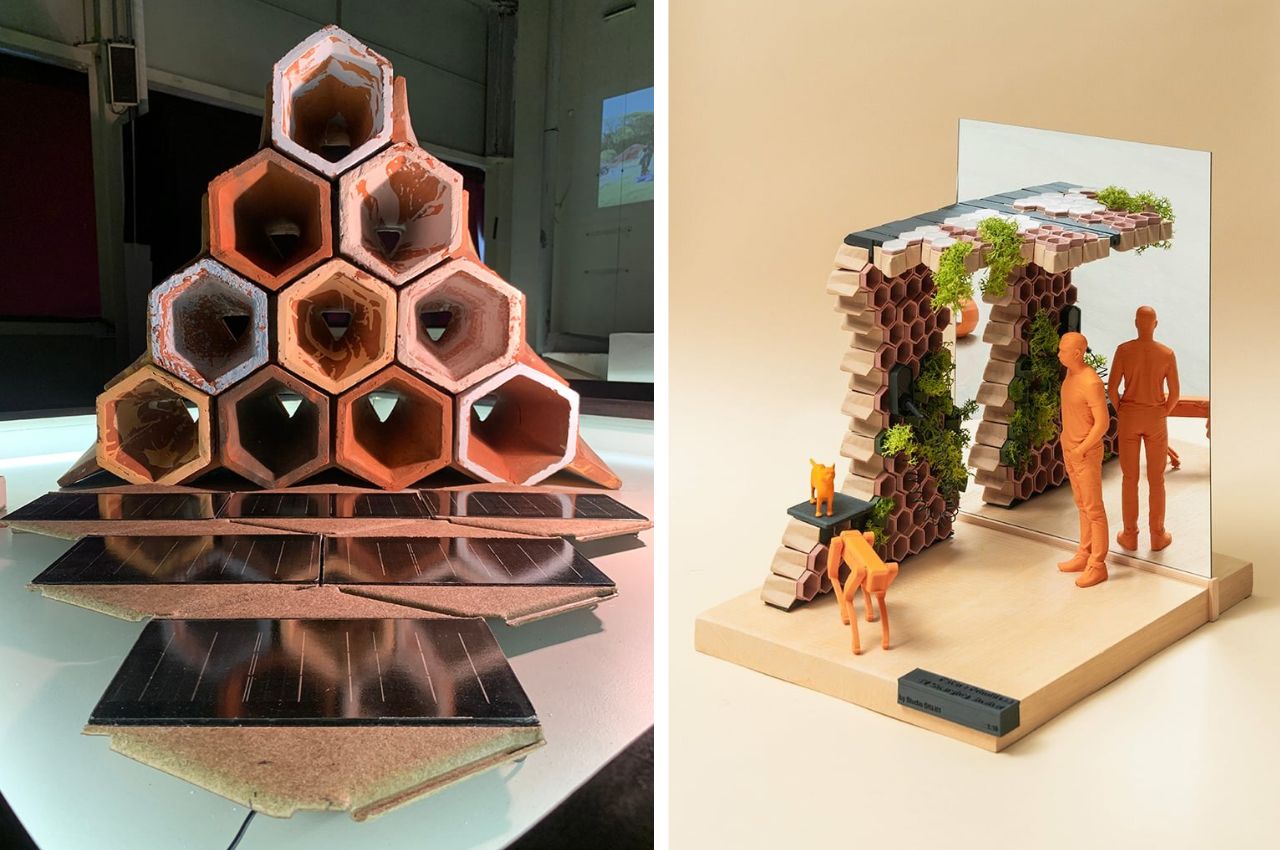

One notable application of the Beehive was at the Deki Electronics factory in Noida. The factory faced extreme heat generated by a generator set at its entrance, which posed health risks and reduced productivity for the workers. Ant Studio’s Beehive system provided an economical and effective solution to this problem. The system’s ability to significantly lower temperatures using evaporative cooling proved beneficial in making the working environment more bearable and safe.

While the beehive pattern is an efficient and aesthetically pleasing design, it is important to consider that some people may experience discomfort due to trypophobia, a fear of clusters of small holes. To make the system more inclusive, Ant Studio could explore alternative forms and patterns that provide the same cooling efficiency without triggering trypophobia. This could involve experimenting with different geometric designs or arrangements of the terracotta pots that maintain functional benefits while catering to a wider audience.

The Beehive air-cooling system has garnered international recognition, winning the Asia-Pacific Low-Carbon Lifestyles Challenge and a $10,000 grant from the UN Environment. This accolade underscores the system’s potential to revolutionize cooling solutions globally. Ant Studio has successfully installed Beehive in 20 different locations, including factories and new builds. Despite challenges in standardizing the manufacturing process, which relies on local potters and craftsmen, the startup continues to inspire both artists and energy pioneers in India.

Siripurapu envisions a future where personal cooling systems like Beehive could transform the cooling industry. Instead of cooling entire rooms, these systems could focus on cooling the air around individuals, drastically reducing energy consumption. The Beehive system not only addresses immediate cooling needs but also supports the revival of traditional pottery crafts, generating employment and preserving cultural heritage.

Ant Studio Team

The post Honeycomb-inspired Terracotta Wall can cool houses without any chemicals or electricity first appeared on Yanko Design.