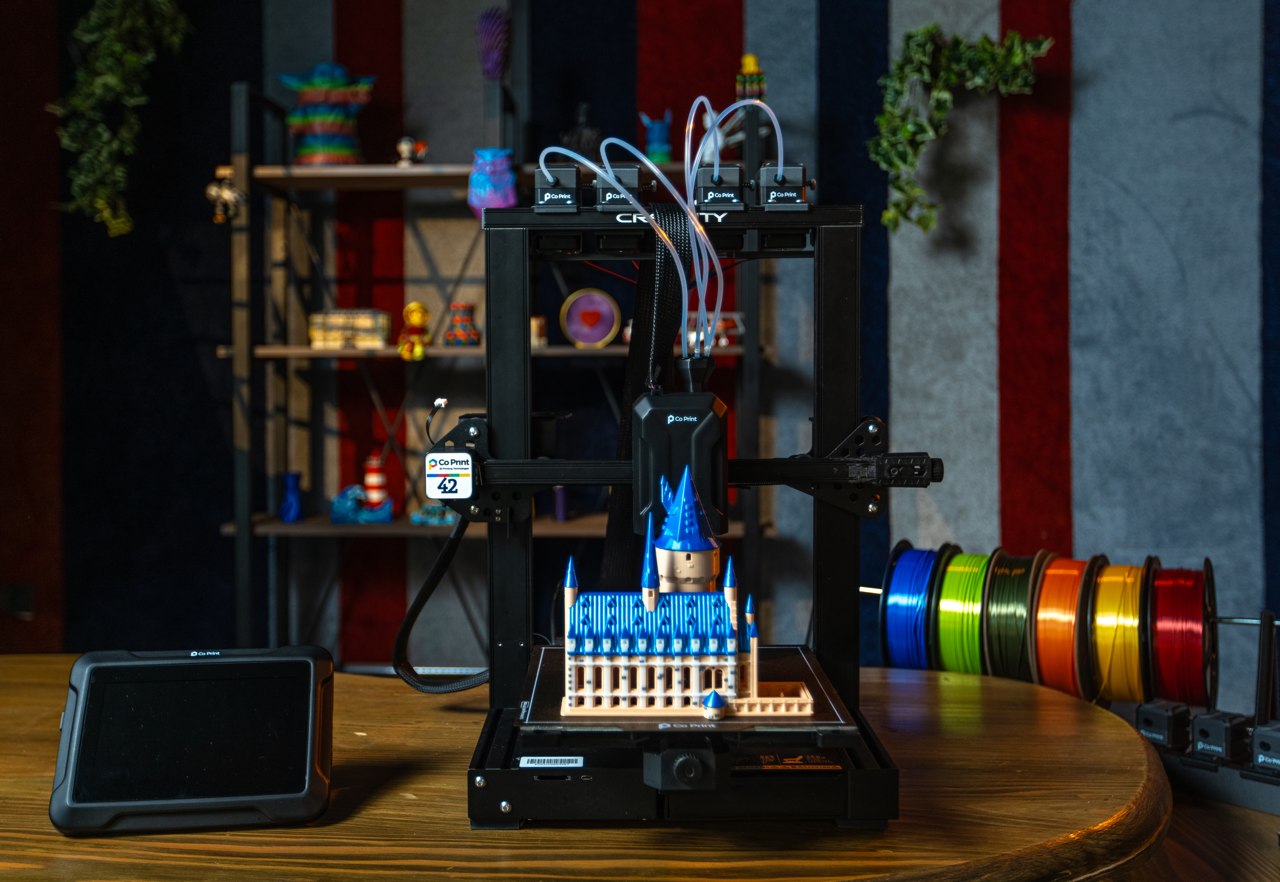

Instead of decking the halls with boughs of holly, deck them with rolls of filament instead! Sure, that doesn’t sound particularly festive at first thought, but it’ll make much more sense when you see these absolutely gorgeous 3D-printed Christmas ornaments we’ve hand-picked for you. We scoured the internet to find some of the most eye-catching 3D prints that perfectly capture the holiday spirit, from geometric snowflakes to some pretty beautiful-looking baubles. Ditch the boring old store-bought ornaments this year, fire up your 3D printer, and make your own (or rent a 3D printer for cheap). They’re sure to add a touch of individuality to your tree this year, they’ll print in mere hours instead of taking days to deliver, and you’ll definitely have people asking you where you got them!

1. Christmas Tree Ornament Set by Popandsicle

Popandsicle’s Christmas Tree Ornament Set is a brilliant way to give your tree a unique aesthetic that’ll have friends and family wondering where you got those ornaments from. The captivating spiral shape of the ornaments instantly catches your eye – even more so when printed in a metallic-colored or shiny filament. Quite literally putting a ‘twist’ on traditional holiday decorations, this set features a range of designs, each optimized for 3D printing in vase mode (or printing upside down). The collection comes in a set of 6 ornaments that print rather quickly, and are free to download off Prusa’s Printables website.

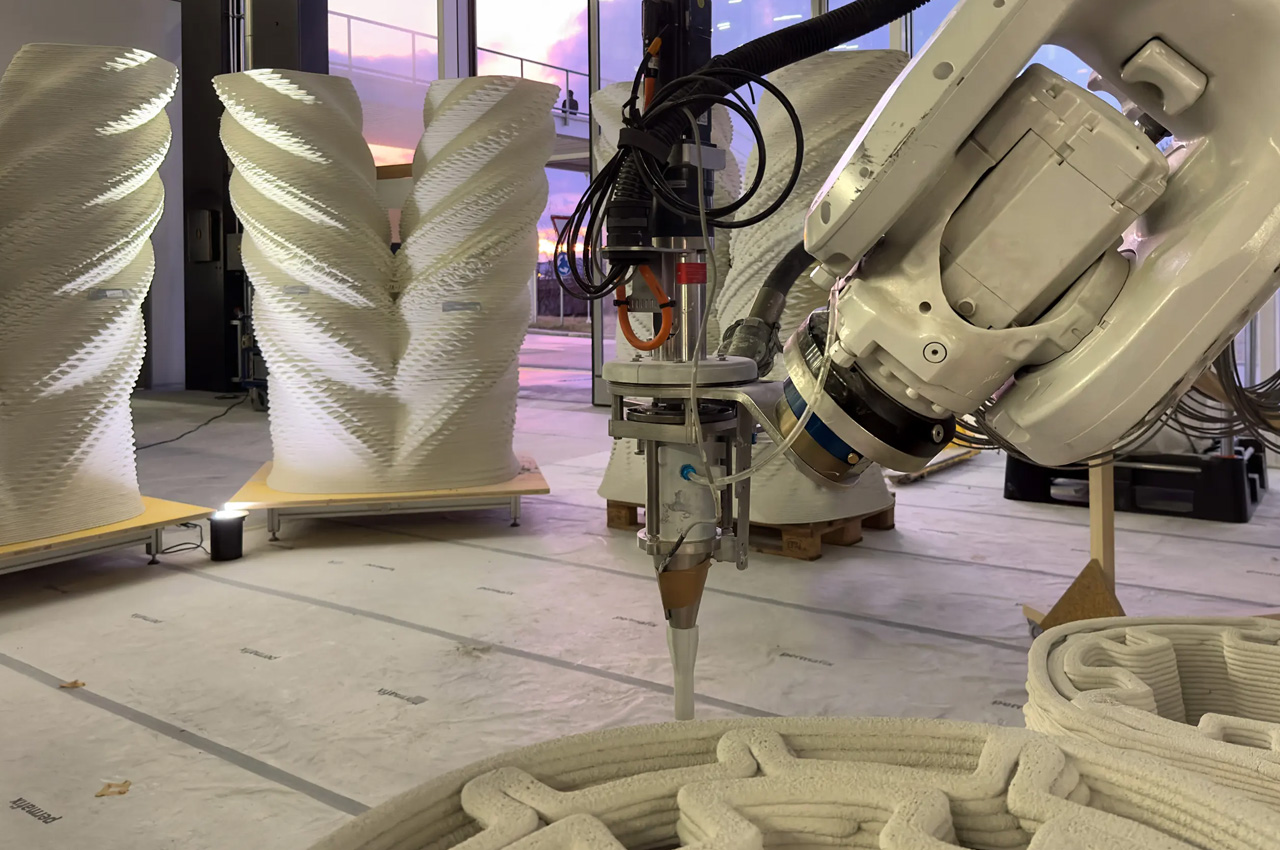

2. Christmas Village by FiveNights

Less for your treetop and more for the tabletop, this 3D-printed Christmas Village is just a glorious little project with a lot of intricate details that make it a nice challenge for the seasoned printing expert. Designed to look like a cosy hilltop village, the print comes with what presumably looks like a snowcapped terrain with roads, rails, houses, and trees galore. The entire print can be done without supports, says the maker, and you’ve got a hatch at the bottom for inserting an LED lamp or your smartphone flash. Once illuminated from the inside, the village really does come to life as light makes its way through the translucent body of the print and through the doors and windows of all the houses. The print files are available for free from Ultimaker’s Thingiverse website.

3. Baby Yoda Christmas Ornament by Psdwizzard

Nothing shows you have elevated eclectic tastes more than having a Baby Yoda bauble hanging from your Christmas tree. Sure, everyone opts for the spheres, lights, stars, and personal photographs, but there’s just something so perfect about your own personal Grogu dressed as Santa hanging from your tree. This decorated character from the Mandalorian comes with its own Santa robe and hat, is is pictured here holding a decorative orb. Printing it is relatively simple, although you will require supports. The entire thing prints in a single color and needs to be post-processed and painted by hand, which should be a fun activity if you’re a fan of the Star Wars universe, eh? The Baby Yoda Christmas Ornament is available to download for free on the Thingiverse website.

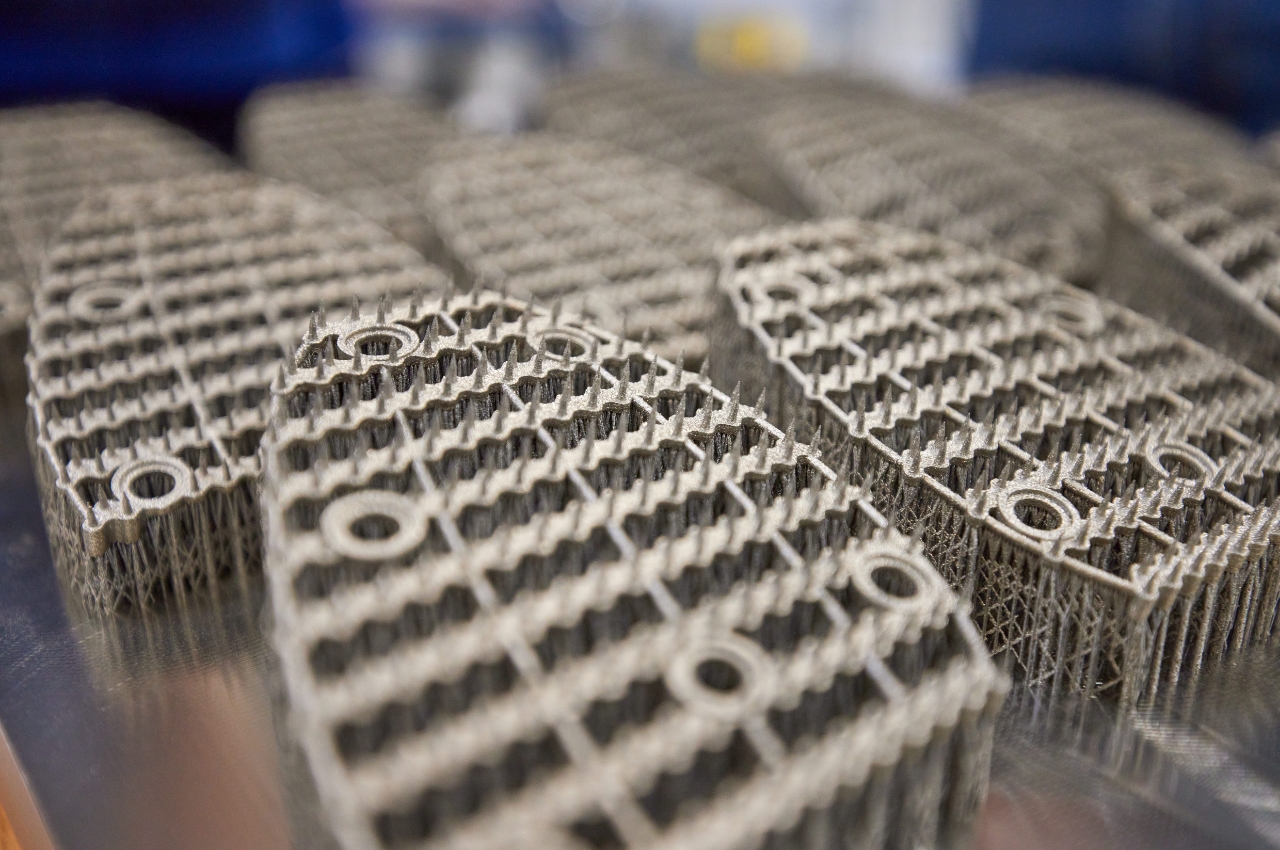

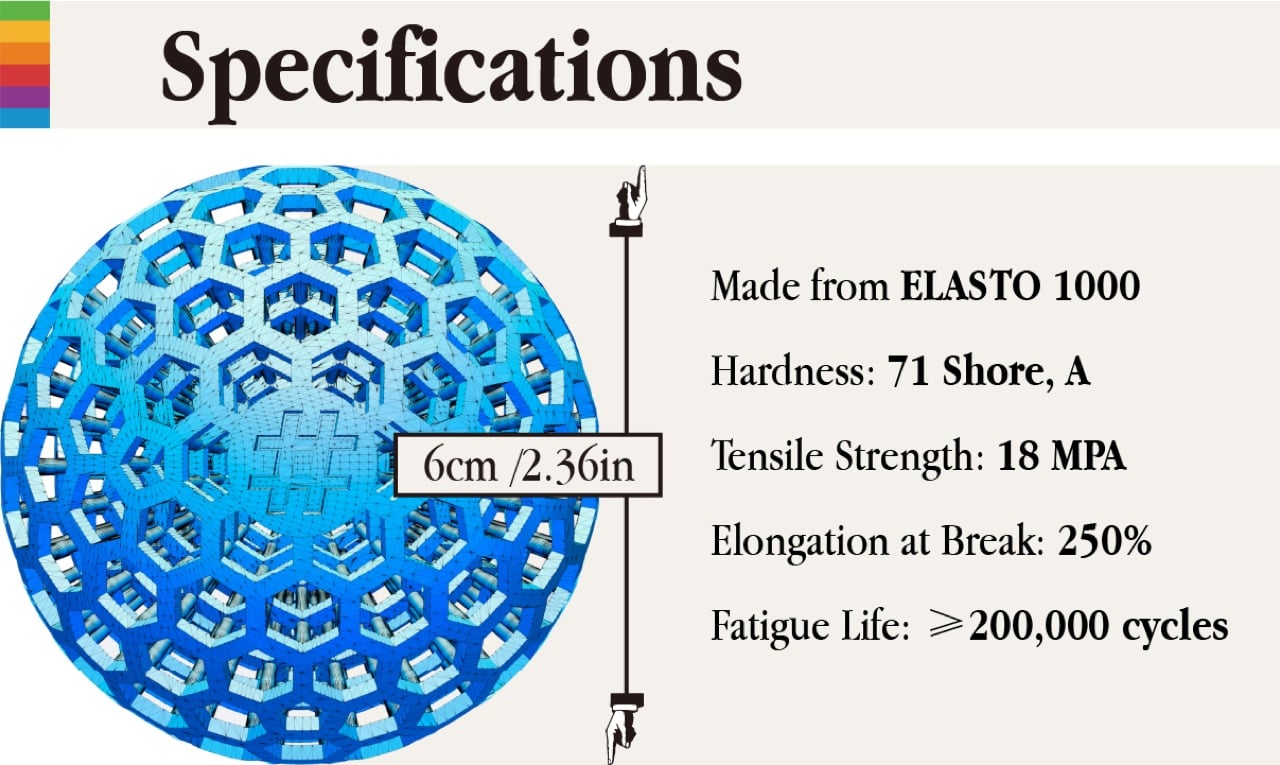

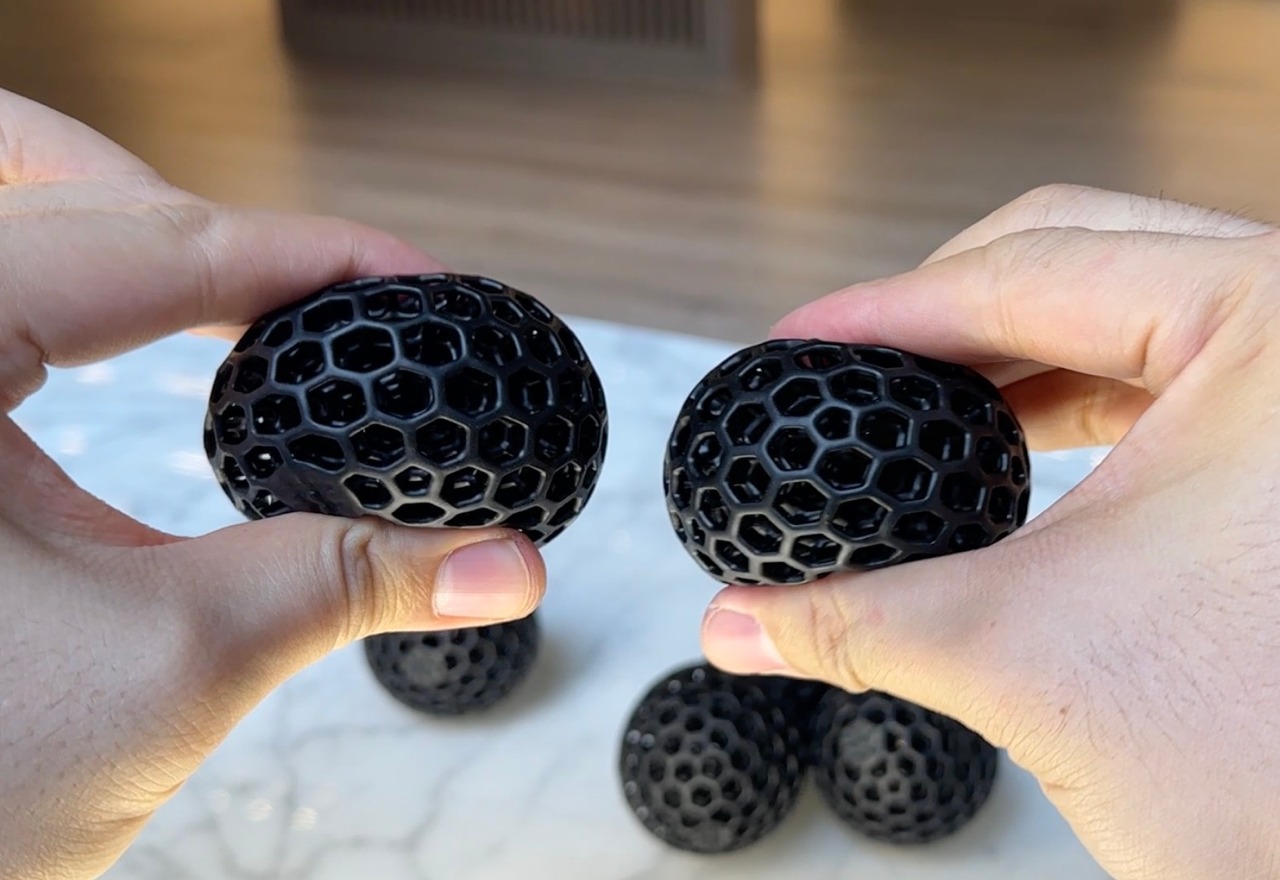

4. Christmas Ball by cunicode

The beauty of these Christmas ornaments from cunicode lies in A. the fact that their complex geometry can only be machine-made using 3D printing, and B. they’re large, eye-catching, but incredibly lightweight, so you can deck your tree with as many of them without them weighing your branches down. “Since 3D Printing costs are driven by volume and material used, I designed the geometry of these balls to use minimum material while keeping maximum strength,” cunicode says. The 3D STL file for the Christmas Ball is available for free on the Thingiverse Website.

5. Deer in the Mountains by jdormer9

Yet another tabletop accessory to bring the holiday spirit, this one gets props for its artistic flair. The Deer in the Mountains print from jdormer9 is an elegant 2D graphic of a deer against white mountains. Artistically, it gets full marks for its uniquely minimalist style, although functionally I would love to have seen a built-in card holder or something that adds a little more value to this piece. However, the beauty of 3D printing is that you can optimize designs to suit your own needs. Heck, add a card-holder at the back, turn the deer’s antlers into a keychain holder, go wild! The Deer in the Mountains 3D file is available for free on the Printables website.

6. Christmas Spiral Teardrop 2023 by Scott McClurg

Scott McClurg, who also goes by his internet moniker ‘dazus’ is a pretty big deal in the 3D-printed ornament space. McClurg’s works combine geometry with tradition, resulting in some of the most hypnotic, kaleidoscopic Christmas decorations your eyes will ever see. The 2023 Christmas Spiral Teardrop is remarkable to look at, especially given that it’s printed using a plastic filament with a silver-gold metallic finish. The ornament’s undulating interweaving surfaces catch light beautifully, creating wonderful contrasts that are further punctuated by the hollow spaces. Things get even more interesting when the ornaments spin, creating a hypnotic motion that’s difficult to look away from! The 2023 Christmas Spiral Teardrop, understandably, is one of the more tricky 3D prints to execute. The ornament needs quite a few supports, McClurg mentions, and there are a few more details to keep in mind while you run this print, which can be found on the Thingiverse website, along with the free 3D file for the ornament.

7. Open Lattice Christmas Bell by Scott McClurg

It was a pretty herculean task zeroing down on just one of McClurg’s ornaments, so here’s another one that we can’t stop admiring. With a similar interwoven hypnotic lattice-esque design like the Christmas Spiral Teardrop, the Open Lattice Christmas Bell is a gorgeous themed ornament that adds gravitas and pizzazz to your tree without adding any weight. Its complex design does present a few challenges while printing, but it’s nothing a seasoned 3D printing enthusiast can’t handle. We recommend using a metallic-finish filament to give the bell some shimmer! The Open Lattice Christmas Bell is free to download on the Thingiverse website.

8. Gimbal Christmas Ornament by Jouni Ahola

Complex 3D prints are great, but what about kinetic ones? This Gimbal Christmas Ornament isn’t the kind you’d just hang on your tree and forget about. With multiple joints, it’s the kind of ornament you’d want to fiddle with, adjusting, readjusting, and fidgeting just because it’s so much visual and tactile fun. Designed to be a single-print design, this marvel from Jouni Ahola prints flat, but can then be flipped around like a Rubik’s cube, or more accurately, a gimbal. Like the rest of the ornaments, this one too is free to download, and can be found on the Thingiverse website.

9. Merry Bird Christmas Ornament by Michiel Cornelissen

Call it an adorable ornament or a metaphor for a certain social media company, this bird-in-a-cage ornament is lightweight and exceedingly charming to look at, even though it’s literally a print of a bird trapped inside a Christmas ornament. It has all the hallmarks of a good 3D printed ornament, with its lightweight, hollow, yet intricate design. The bird is hinged, which means it swings to and fro inside its spherical cage, and although it isn’t available for free like any of the other ornaments, you can directly buy it from the Shapeways website and they’ll print it out and send the ready ornament directly to your doorstep!

10. Trippy Snowflake Kinetic Sculpture by JBV Creative

Less of an ornament and more of a kinetic toy, the Trippy Snowflake Kinetic Sculpture is something you’ll constantly find yourself reaching for, sort of like a snowglobe but more enchanting. The multi-part sculpture features a geared mechanism that causes two snowflakes to rotate in opposite directions when you crank the handle, creating a hypnotic, alluring optical illusion. Perhaps one of the most complex and lengthy builds in this collection, the sculpture has multiple parts and components that need to be printed separately (although if you have a large print bed you can print multiple parts at the same time). Given how detailed and thorough it is, this print isn’t available for free either, and the STL file will cost you $45, but the benefit is that once you buy the file, you can print as many of these as you want! Heck, gift them to friends as stocking stuffers too! You can buy the Trippy Snowflake Kinetic Sculpture 3D file on the JBV Creative website.

The post Top 10 3D-Printed Ornaments to Upgrade your Christmas Tree Decoration Game first appeared on Yanko Design.