Most screwdrivers and multi-tools do their job but feel generic, with rubbery handles, loud colors, stamped metal, and no reason to carry them unless you have to. Modern life involves low-level tension, loose screws on glasses, small repairs, idle hands in long meetings, and the constant search for something to occupy fingers without annoying everyone nearby. MAGICDRIVE is aimed at people who want a tool that matches their EDC mindset rather than just filling a slot in a toolbox they rarely open.

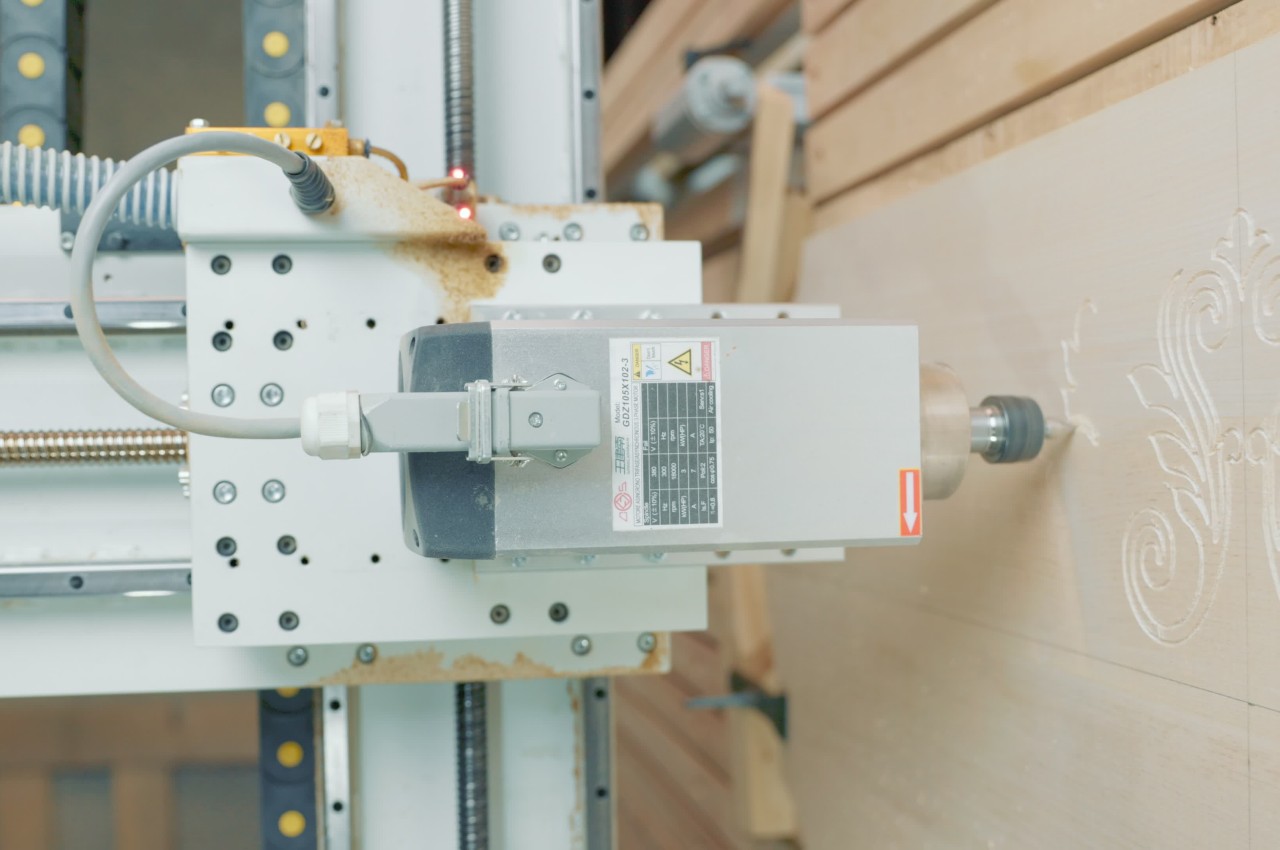

MAGICDRIVE is a precision-machined titanium ratchet screwdriver that tries to be a tool, a toy, and a small piece of mechanical art in one body. It is engineered for real performance, with a CNC-machined ratchet, foldable angles, and modular bit holders, but also designed for lifelong delight, something you might leave on a desk or carry in a pocket organizer because you enjoy using it, not just because you need it when something breaks.

Designer: Thomas Lee

Click Here to Buy Now: $149 $199 (25% off). Hurry, only 48/100 left! Raised over $128,000.

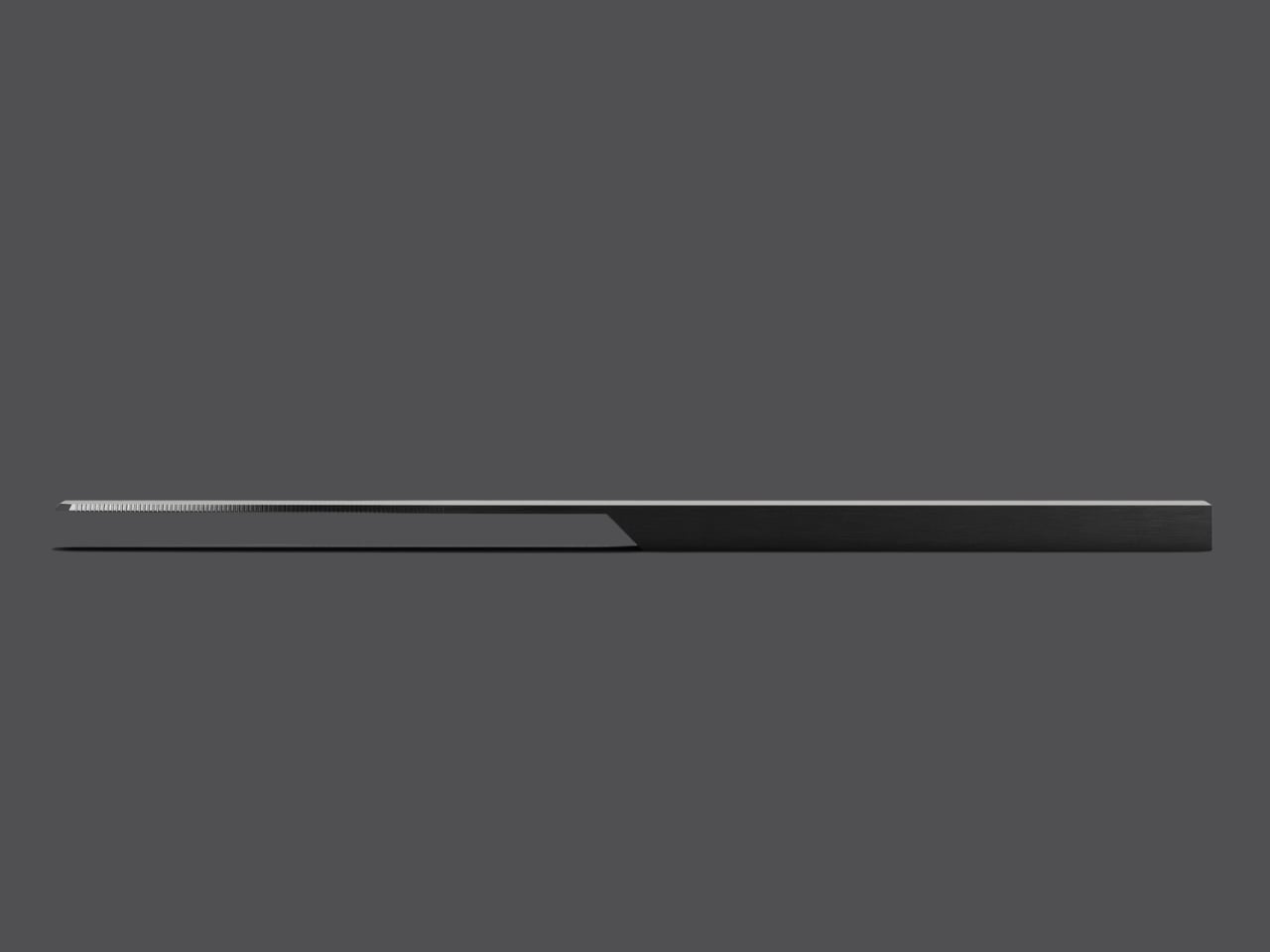

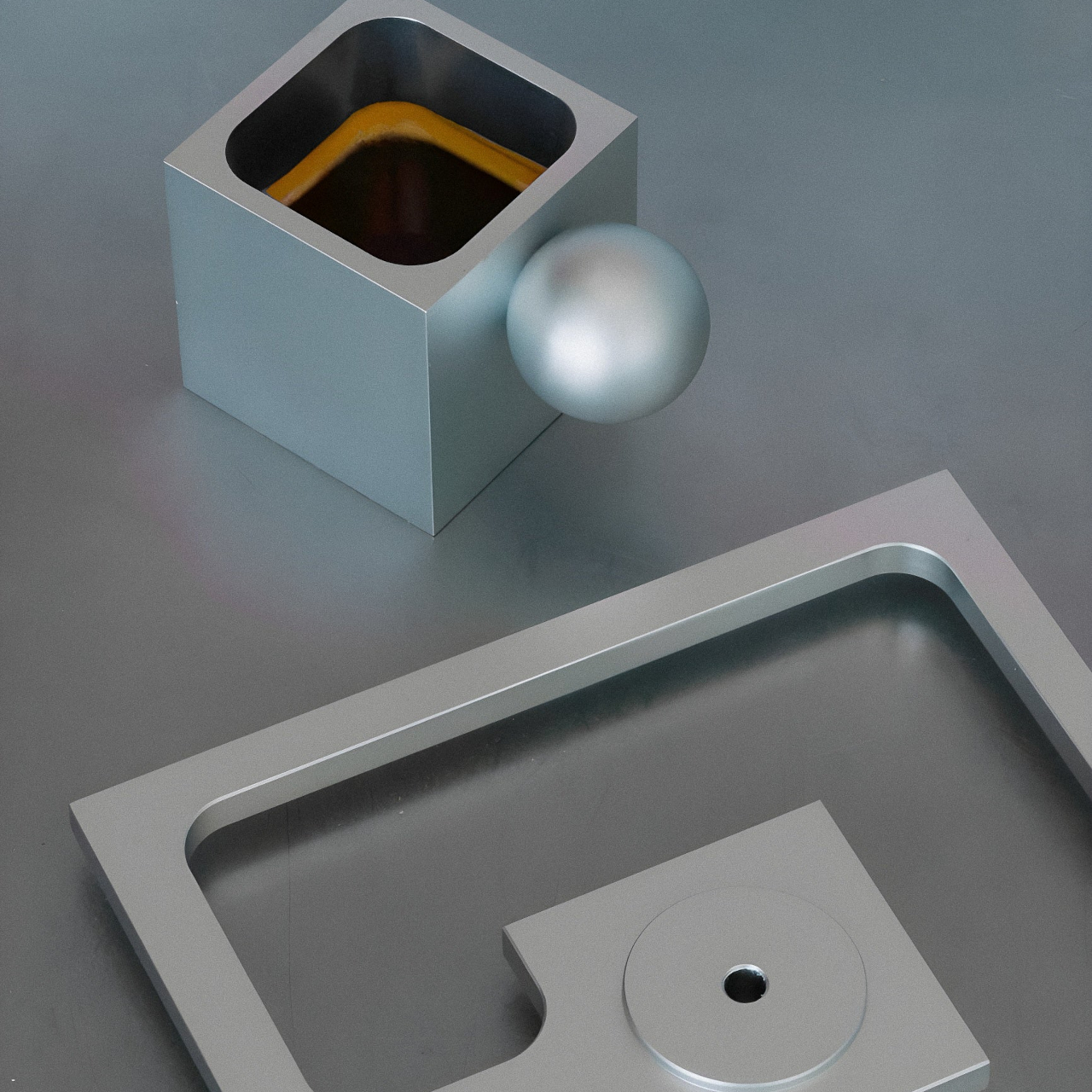

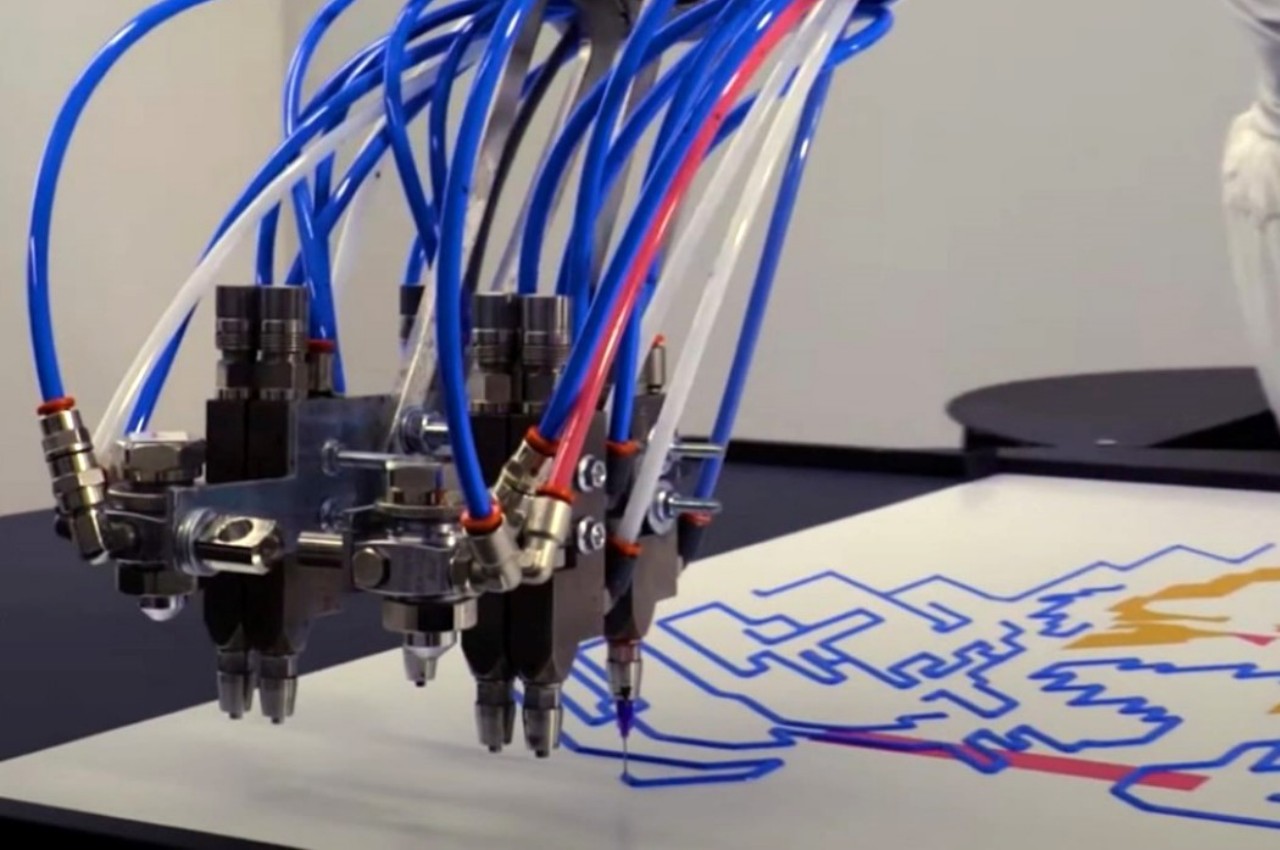

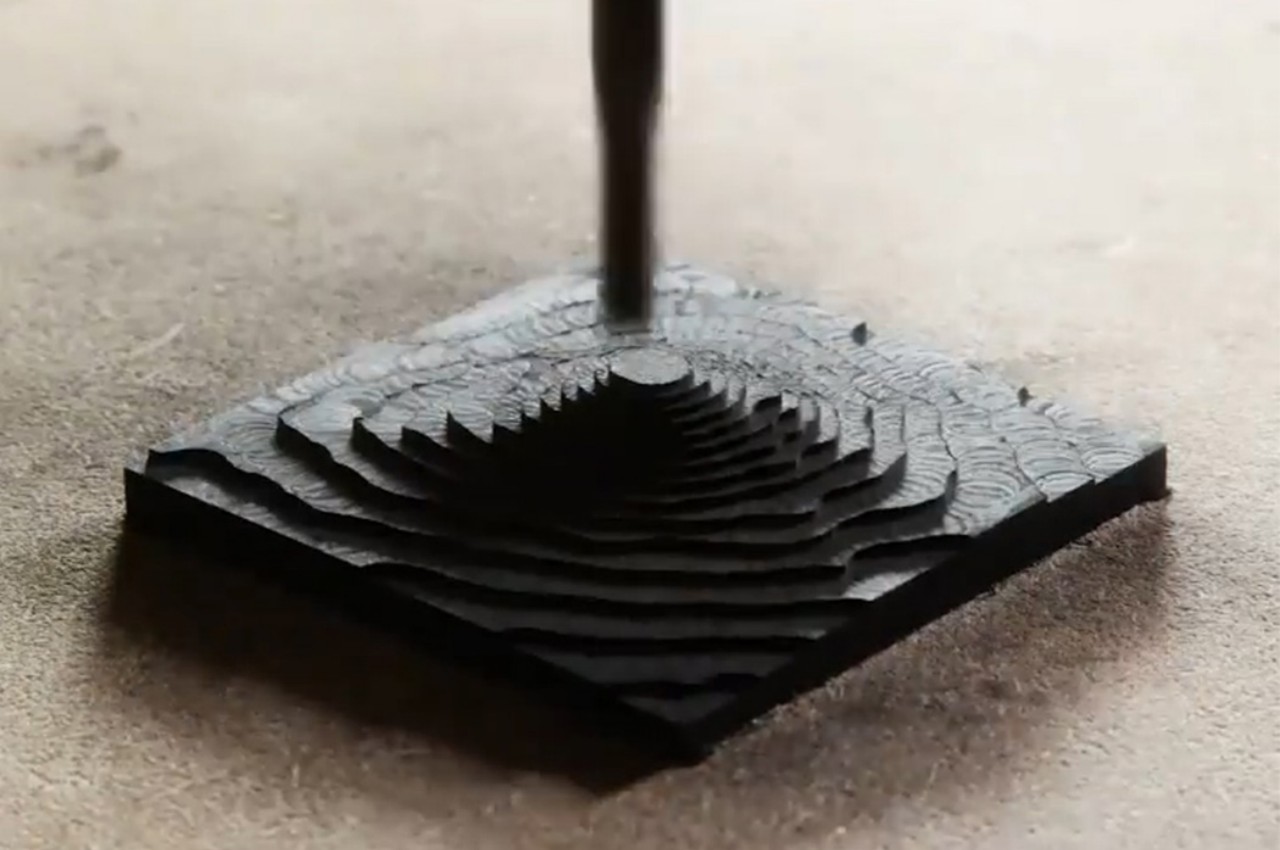

The ratchet mechanism is a fully CNC-machined assembly in titanium, brass, and ceramic bearings, with no injection-molded or stamped parts, built around a classic mechanical design. Every component is individually machined and mechanically interlocked, delivering smooth, solid clicks, strong torque transfer, and the promise of zero wobble and long-term reliability. The knurling is also CNC-machined, grooves cut rather than pressed, giving a confident grip that feels secure without being abrasive during longer sessions or repeated use.

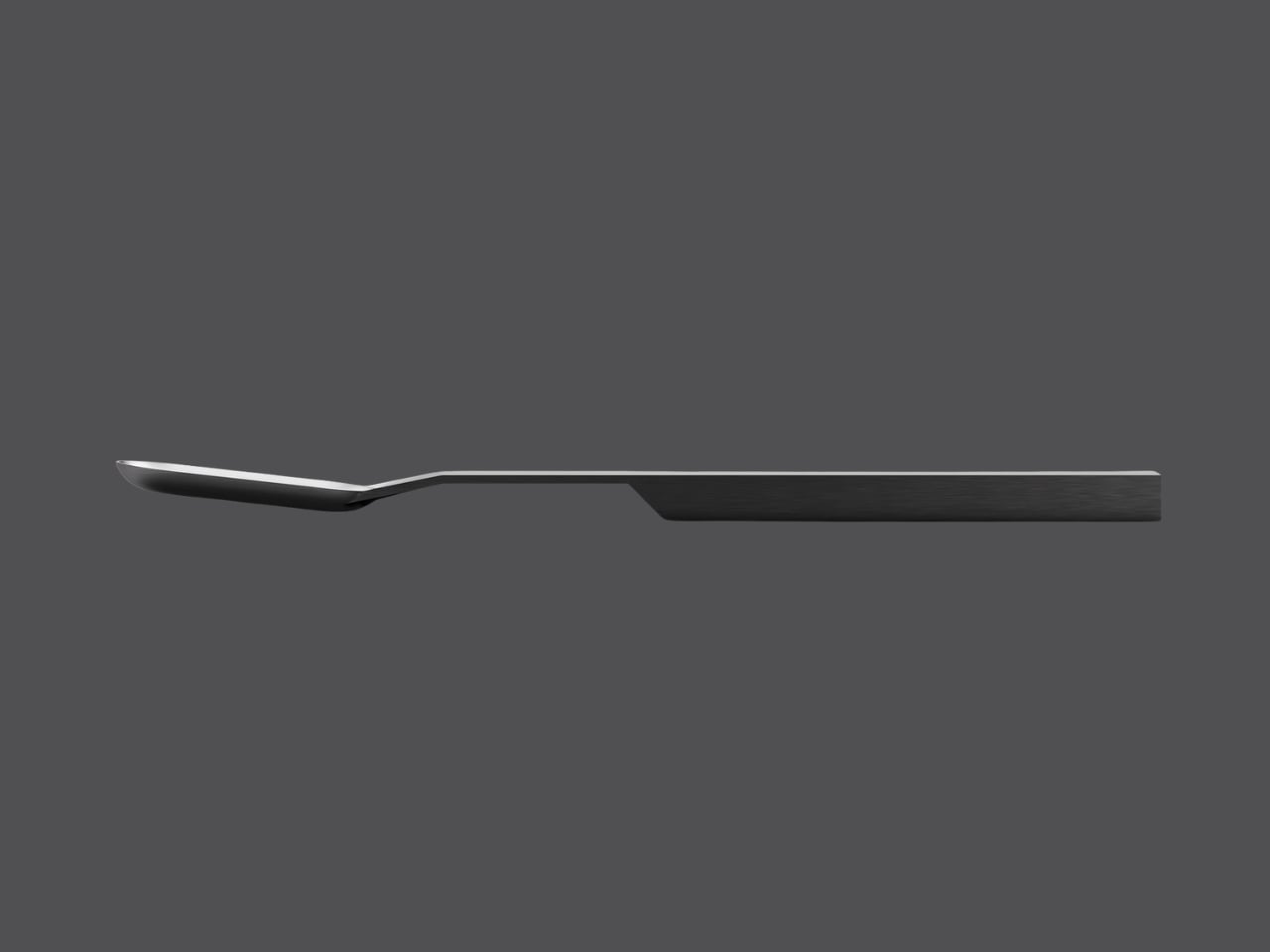

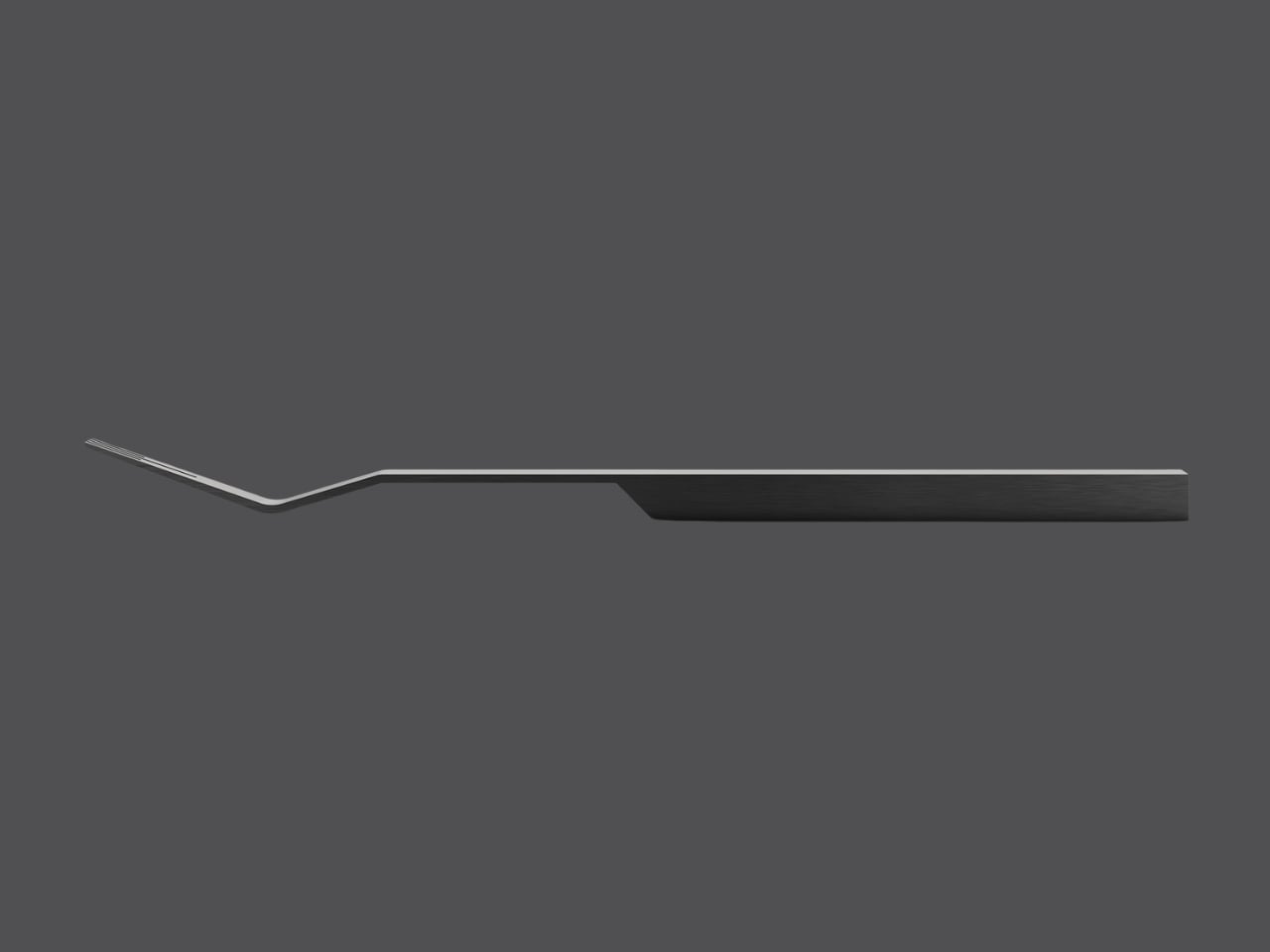

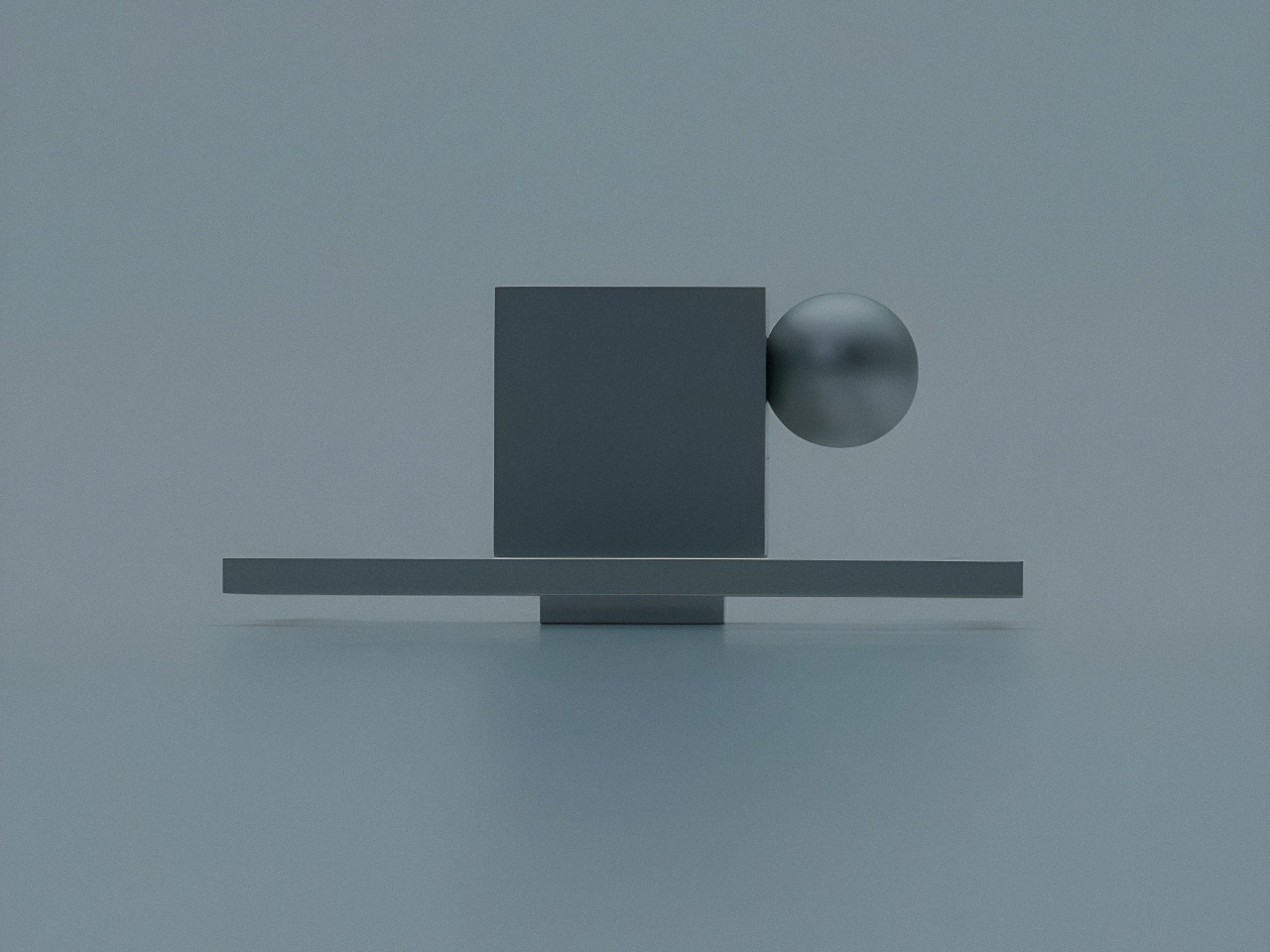

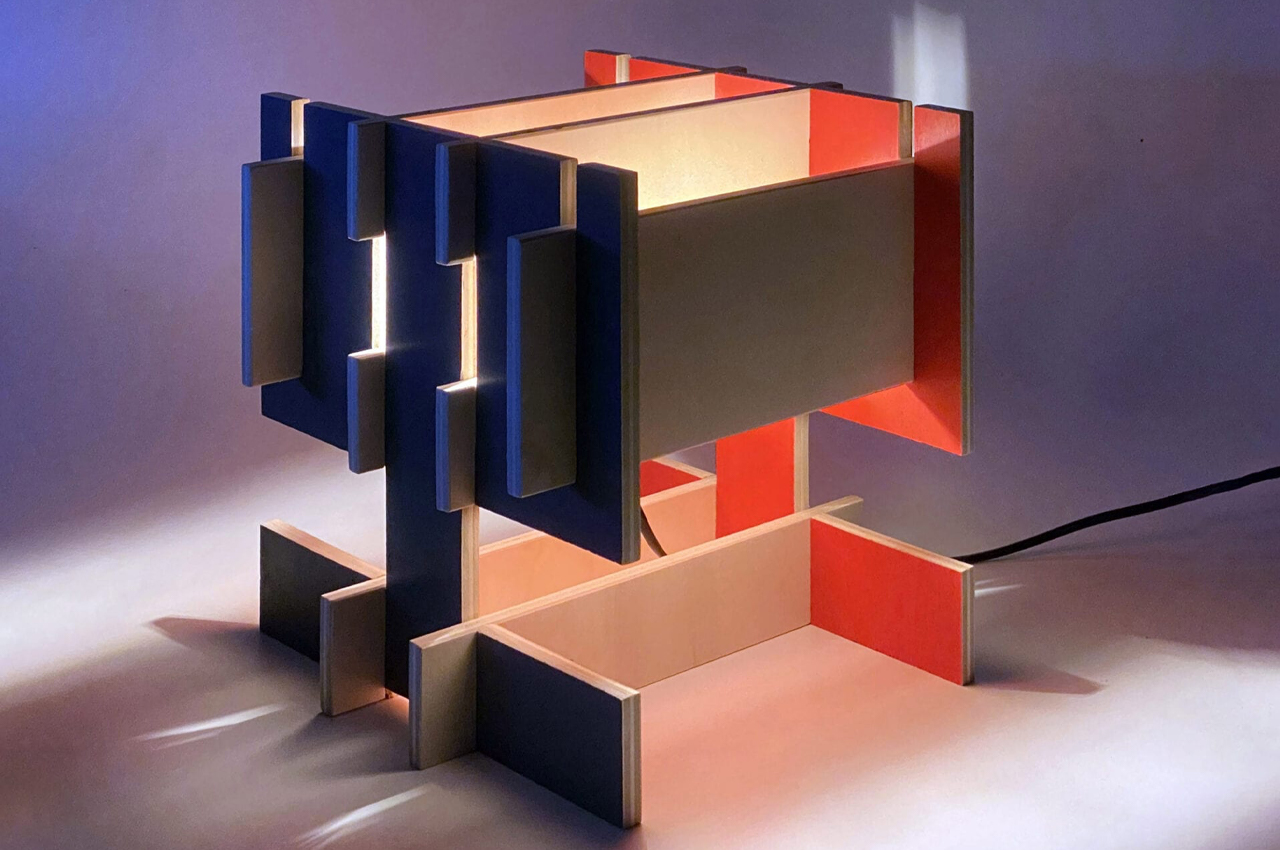

The foldable body locks into 0°, 45°, and 90° positions with a push-button system. Straight-line mode is for rapid spinning and quick turns, 45° mode adds control and comfort, and 90° mode turns the compact driver into a small lever for stubborn screws and awkward angles. Torque testing measured up to 7.9 N·m in 90-degree mode with the 1/4-inch holder installed, which is more than most screws can take before they strip or fail.

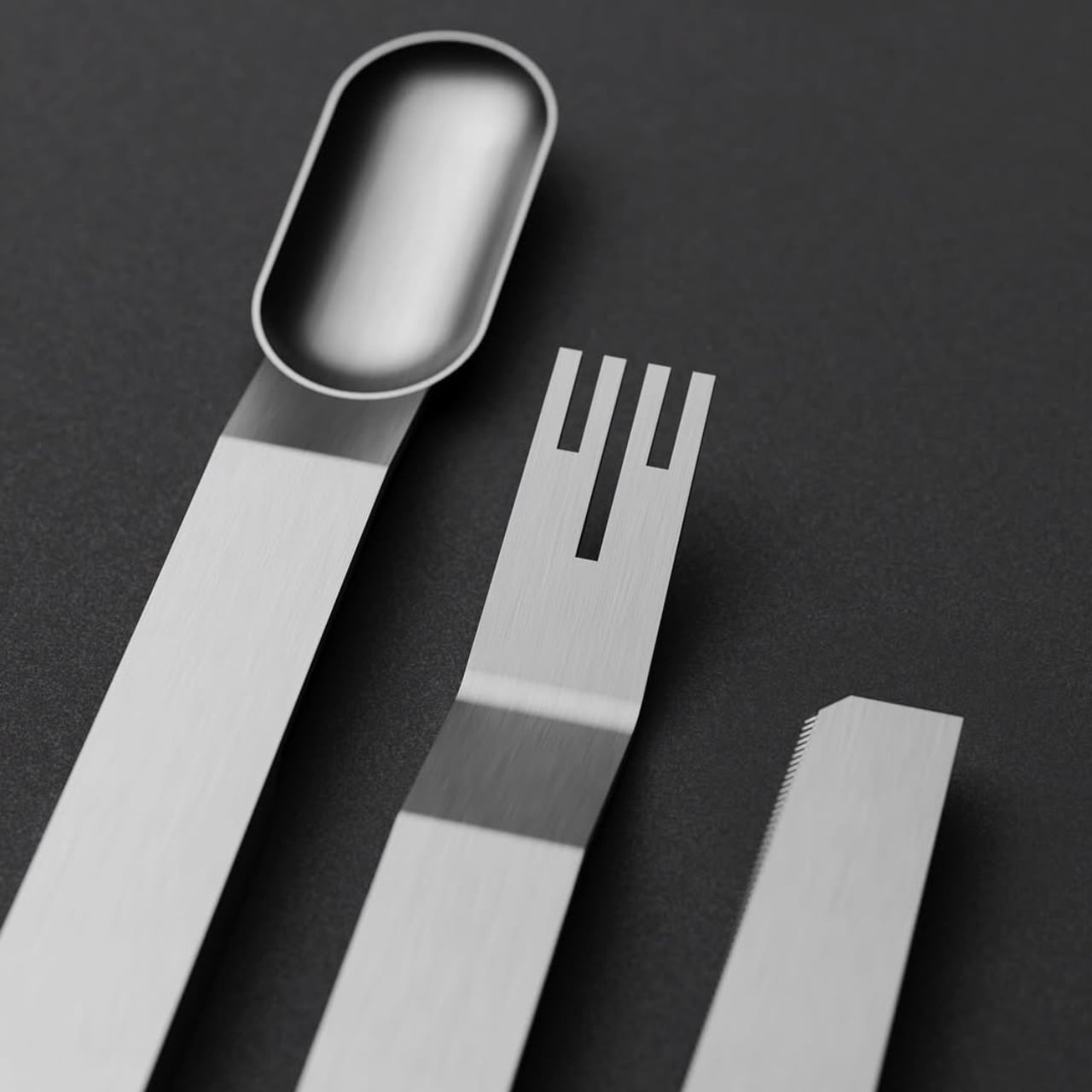

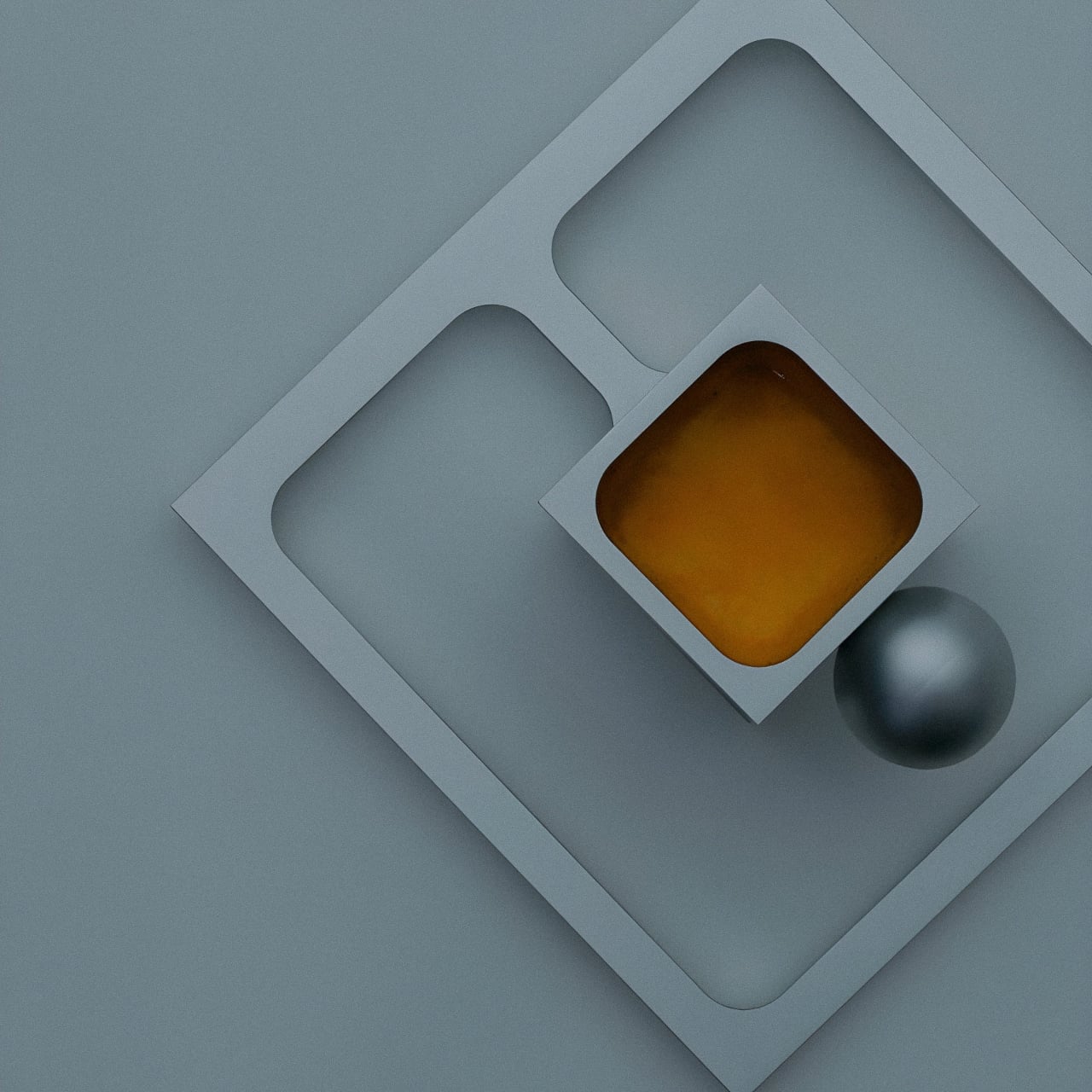

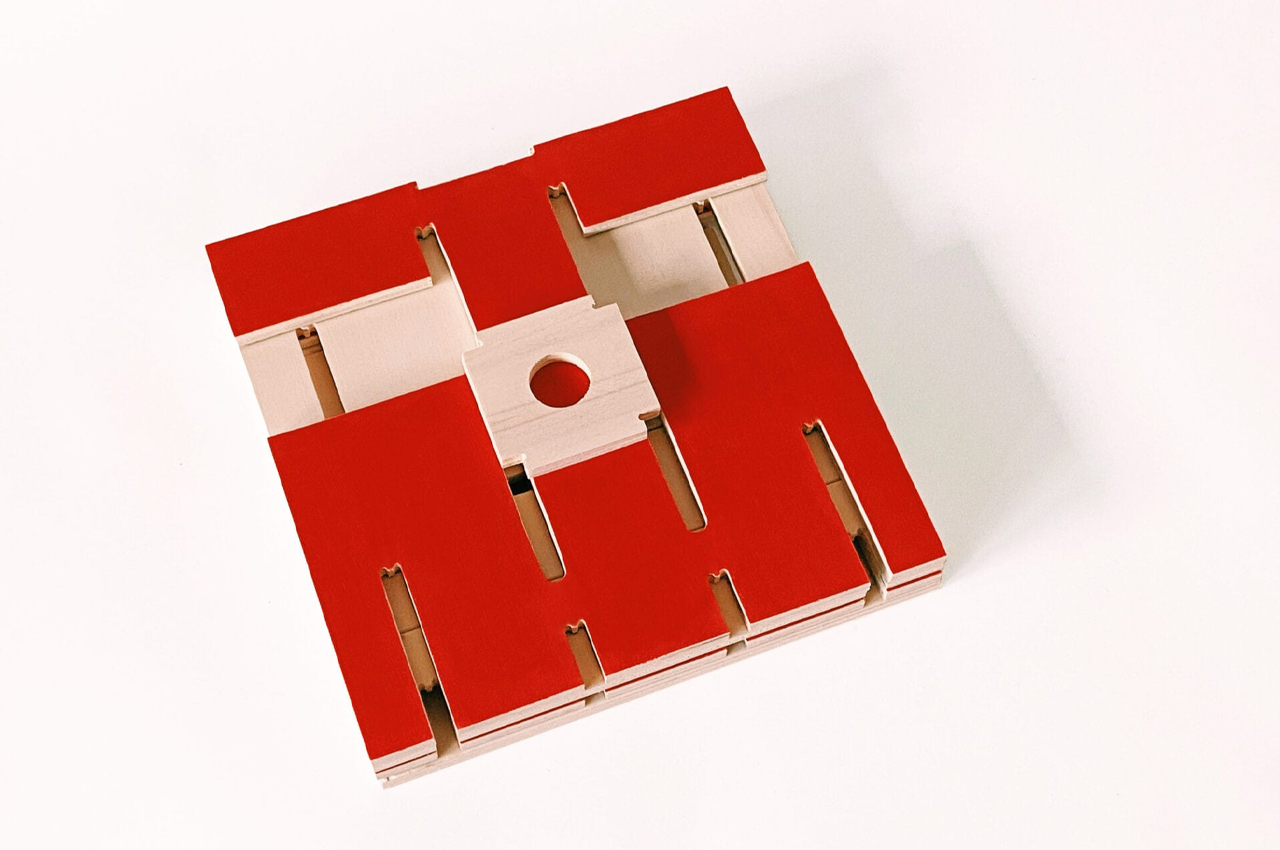

The modular bit system lets you swap between a standard 6.35mm (1/4-inch) bit holder and a 4mm precision bit holder using a magnetic quick-swap interface. The 1/4-inch mode is the workhorse, fully compatible with common bits, extension bars, and socket adapters, likely the configuration you use most for everyday screws, small repairs, and workshop tasks where full ratchet engagement and smooth mechanical feedback matter during tightening or loosening.

The 4mm module is for micro jobs and delicate hardware, eyeglasses, small electronics, cameras, watches, keyboards, and calibration tasks where control is more important than torque. This mode intentionally skips the ratchet to give fingertip finesse, and MAGICDRIVE’s compact form makes it feel closer to a surgical instrument than a bulky driver when you are working on tiny fasteners that need gentle, precise turns without stripping delicate threads.

The quick-swap bit holder is held by a strong magnetic interface designed to avoid accidental separation or rattling during carry. The magnets are mechanically sealed by CNC-machined caps instead of just glued, preventing glue fatigue and loose parts over time. This reinforces the theme that the tool is built for long-term reliability, not just initial impressions or the first few months of use before parts start failing.

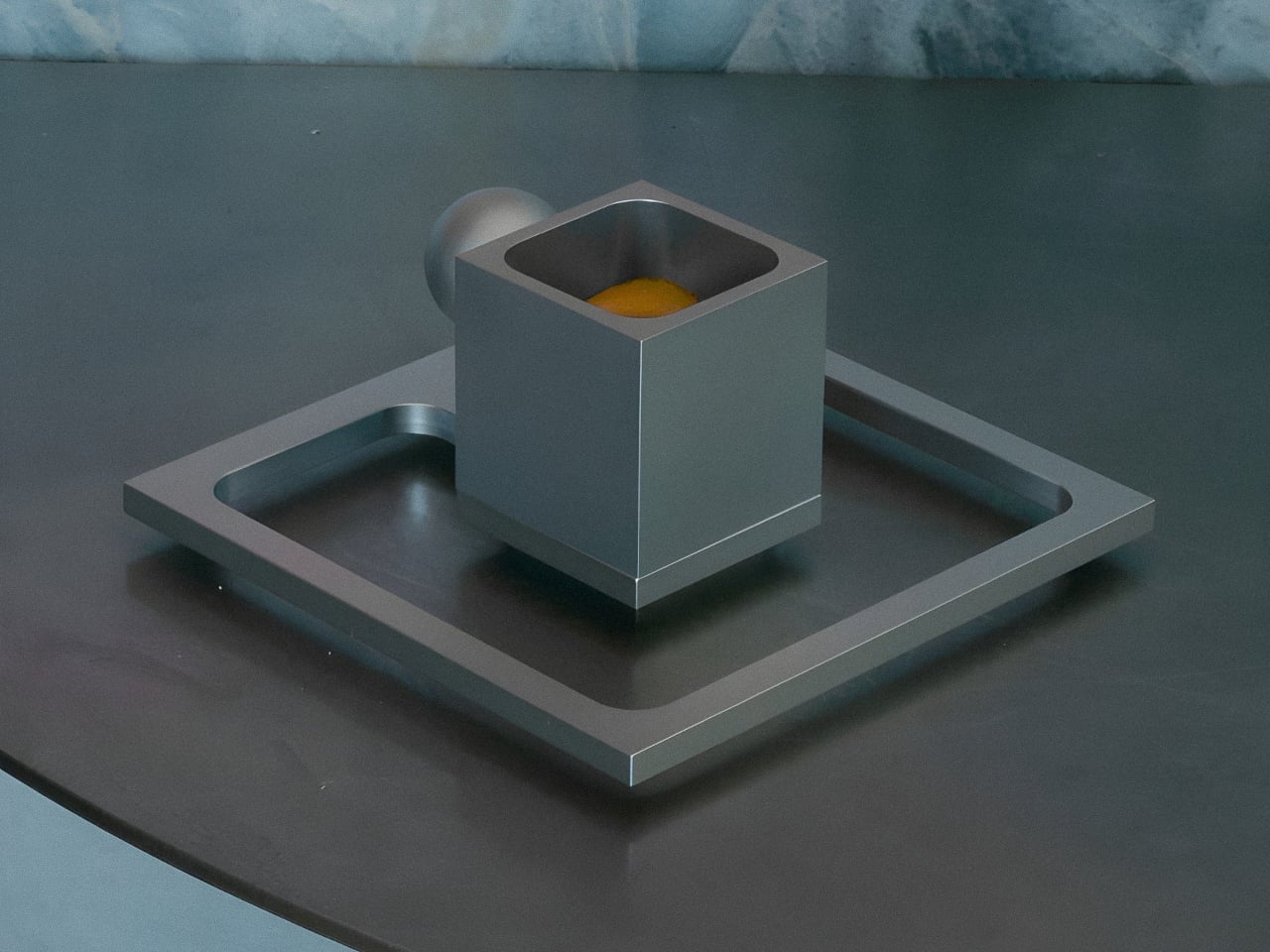

The balanced spinner top with a brass core is designed for silent, satisfying spins when there is nothing to fix. It offers a moment of focus without clicks or noise, and three tritium slots in the top make the driver easy to find in low light while adding a subtle glow when it spins. It is a small piece of kinetic art that turns idle moments into something more intentional, quieter than clicking a pen and more deliberate than scrolling through a phone.

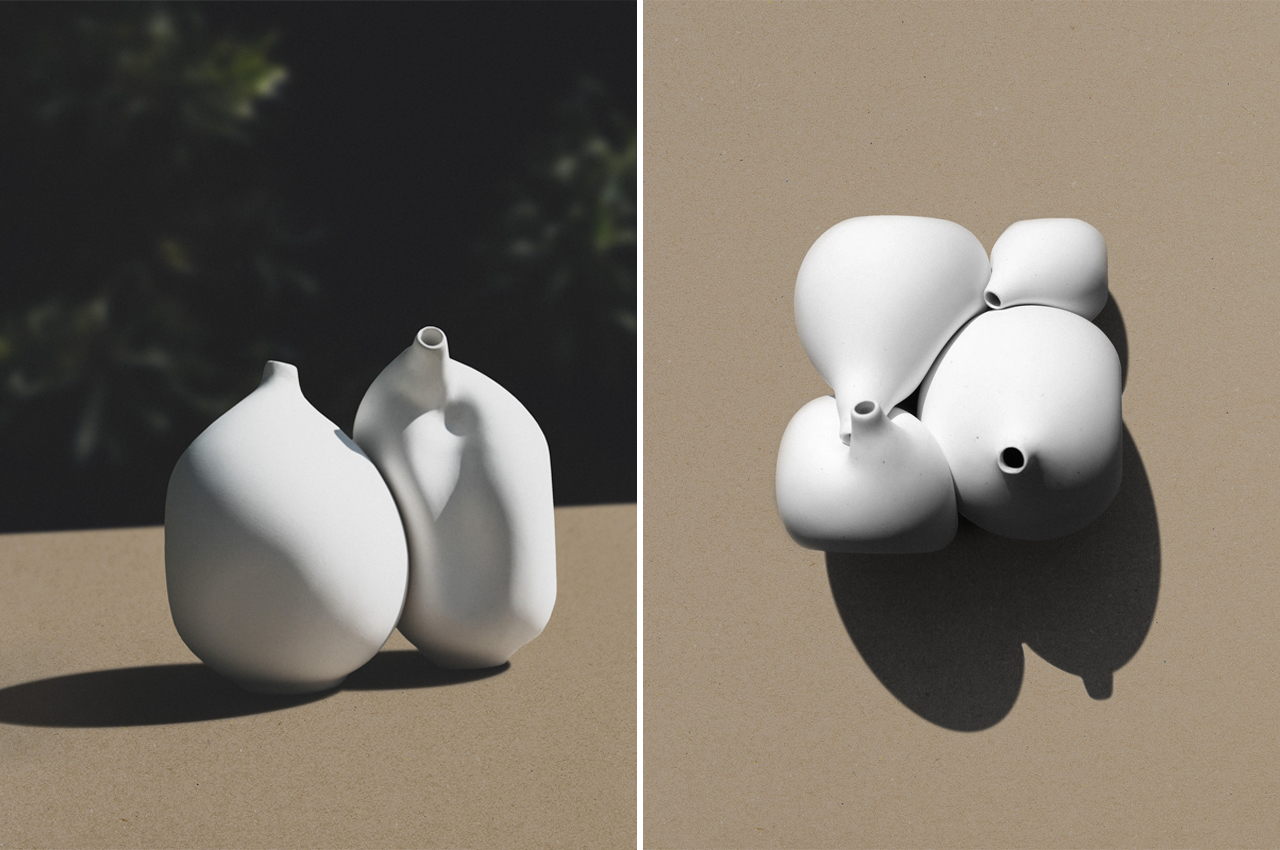

The Grade 5 titanium body, brass spinner core, and N56 magnets avoid coatings pretending to be metal. Three finishes are available: satin silver, beadblast matte grey, and PVD black, and the brass develops patina over time. The hex-based modular ecosystem includes pen and knife modules and an aluminum bit-holder magazine with a ruler and storage, framing MAGICDRIVE as a platform that can grow with an EDC setup rather than a single-purpose tool that sits in a drawer.

MAGICDRIVE is meant to live beside a favorite knife, pen, or watch, not buried in a drawer. Sometimes you pick it up to fix something, sometimes just to feel the machining under your thumb or spin the top during a long call. It is a screwdriver that treats function and feeling as equally important, turning small interruptions and small repairs into chances to enjoy a beautifully made object. For people who care about the tools they carry and the rituals that fill the gaps between bigger tasks, MAGICDRIVE reads less like a gadget and more like a small, well-resolved piece of everyday gear that earns its place in a pocket or on a desk.

Click Here to Buy Now: $149 $199 (25% off). Hurry, only 48/100 left! Raised over $128,000.

The post This CNC Titanium Screwdriver Has a Spinner Top You Can’t Stop Touching first appeared on Yanko Design.