Along with apples, bananas are the most popular fruits in the world. More than 100 billion bananas are eaten every year, with most of us consuming about 30 pounds worth of bananas every year– that’s bananas. But what happens to all the banana peels we toss out after eating the fruit? Generally, if thrown outdoors, it can take up to two years for banana peels to biodegrade. Sarah Harbarth, a designer based in Switzerland, saw the potential in turning banana peels into a sustainable source of construction material, calling it KUORI.

Harbarth was able to create four distinct products that are entirely compostable and made from banana peels. Harbarth’s first product shows a pair of eyeglasses that swap out a tortoise-shell frame for a banana speckled marble one. Then, in combining recycled PLA material with banana peels, Harbarth produced a 3D printing filament from which one can print anything they’d like. The third product Harbarth created through KUORI is the shoe sole made entirely from banana peels, solving the problem of micro-plastics rubbing off onto the ground as we walk in our street shoes. By replacing the micro-plastic that forms our shoe soles with banana peels, Harbarth created a sole that not only doesn’t disrupt the soil we walk on but feeds it as well. Lastly, in confronting the harmful practice of making leather goods, Harbarth designed a sustainable, vegan, and recyclable leather alternative, which she showcased in the form of a watch strap.

While the time it takes for decomposition to run its course depends on environmental factors, natural litter can have an adverse effect on critters that take to munching on fruit peels and therefore the environment as a whole. With all the bananas we enjoy every year, that same amount is then turned into waste. In order to lengthen the life cycle of bananas and combat the harmful and wasteful practices of making leather goods from animal skins, Harbarth was able to create goods like phone cases and watch straps entirely from banana peels. Upon recognizing the intricate ways in which we contribute to harming the environment through practices like leather making, 3D printing, and micro-plastic construction, Harbarth looked to using banana peels to produce goods instead.

Designer: Sarah Harbarth

By turning banana peels into an alternative building material, like leather, KUORI is sustainable, vegan, and saves resources.

“The result [of KUORI] is four products that are 100% compostable and made from the banana peel as an original food waste byproduct.”

In creating products out of banana peels like eyeglasses, KUORI feeds nature instead of taking from it.

“Due to the fiber composite of the Banana peel in the material, the resulting product has a higher stability compared to ordinary PLA.”

Most shoe soles are constructed using micro-plastics that rub off on the ground we walk.

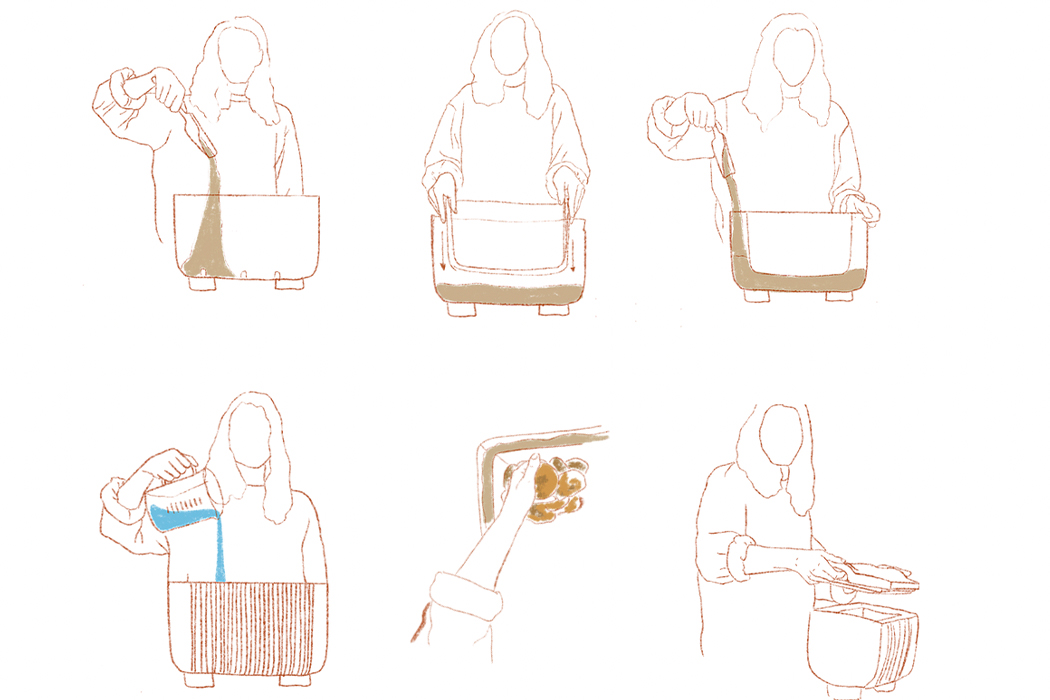

“The resulting shoe sole is very elastic and returns to its original position. The material was poured into a mold and then hardened out.”

Confronting harmful practices like bleaching leather hides, KUORI offers a sustainable alternative.

“My concept represents a sustainable, resource-saving, organic and vegan, recyclable alternative to animal leather.”