According to studies, almost 83% of our every day garbage is not sorted and recycled. That means a lot of it is just thrown into landfills and most of them just stay there rotting for years, maybe even decades. If we are able to properly sort them properly, even just a small percentage, and dispose of them in a more circular manner, including recycling and upcycling, then it will be better for our planet. The problem sometimes though is that people and even machines still don’t know how to sort and recycle properly.

Designer Name: Romain Pellat

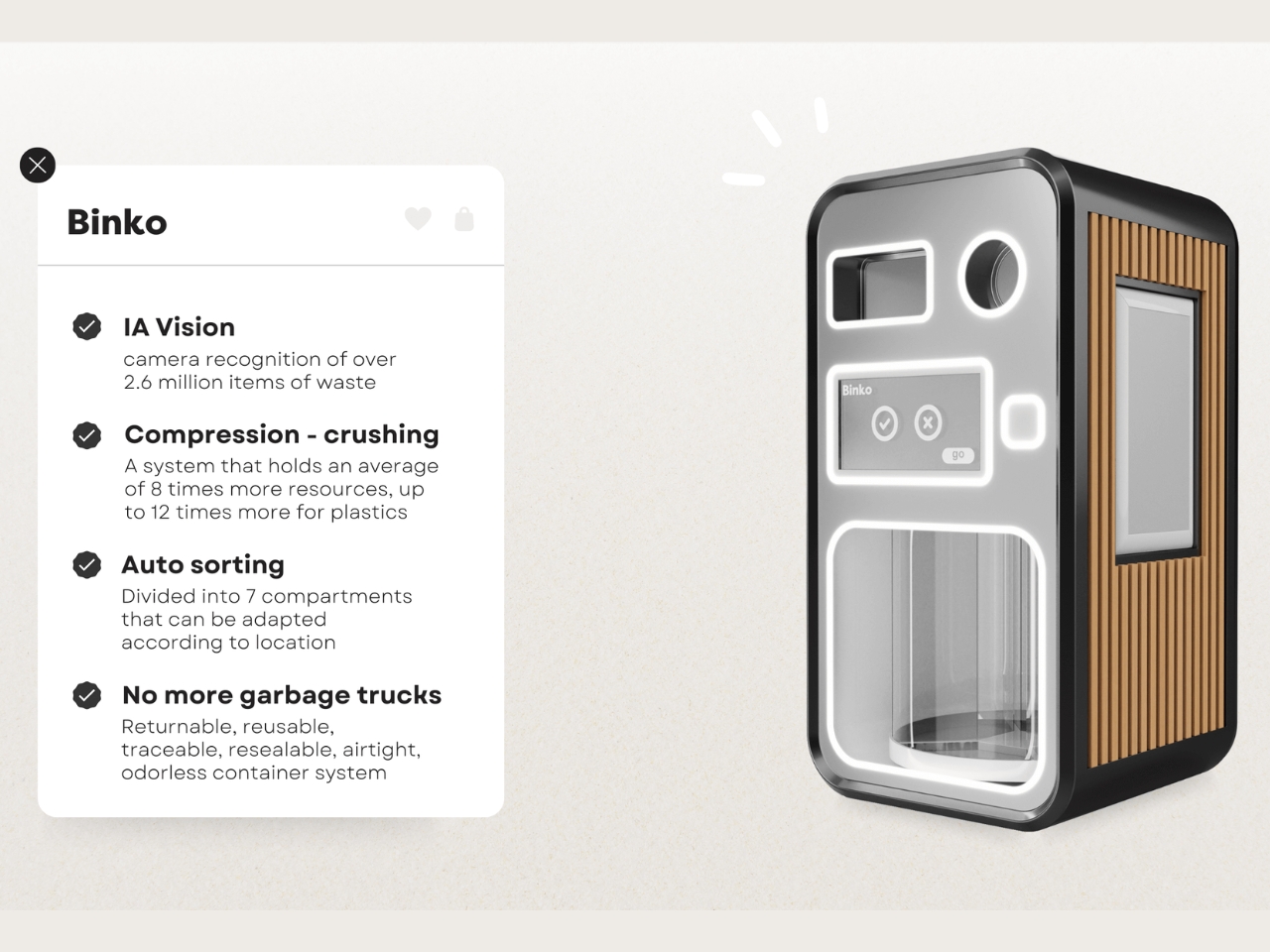

With the advent of robotics and A.I, our garbage disposal should be better. This is what Binko aims to do. It is an AI-powered recycling robot that should help homes and offices to improve the way they do their waste disposal. It is able to auto-recognize the different kinds of garbage, sort them properly, and then crush them accordingly.

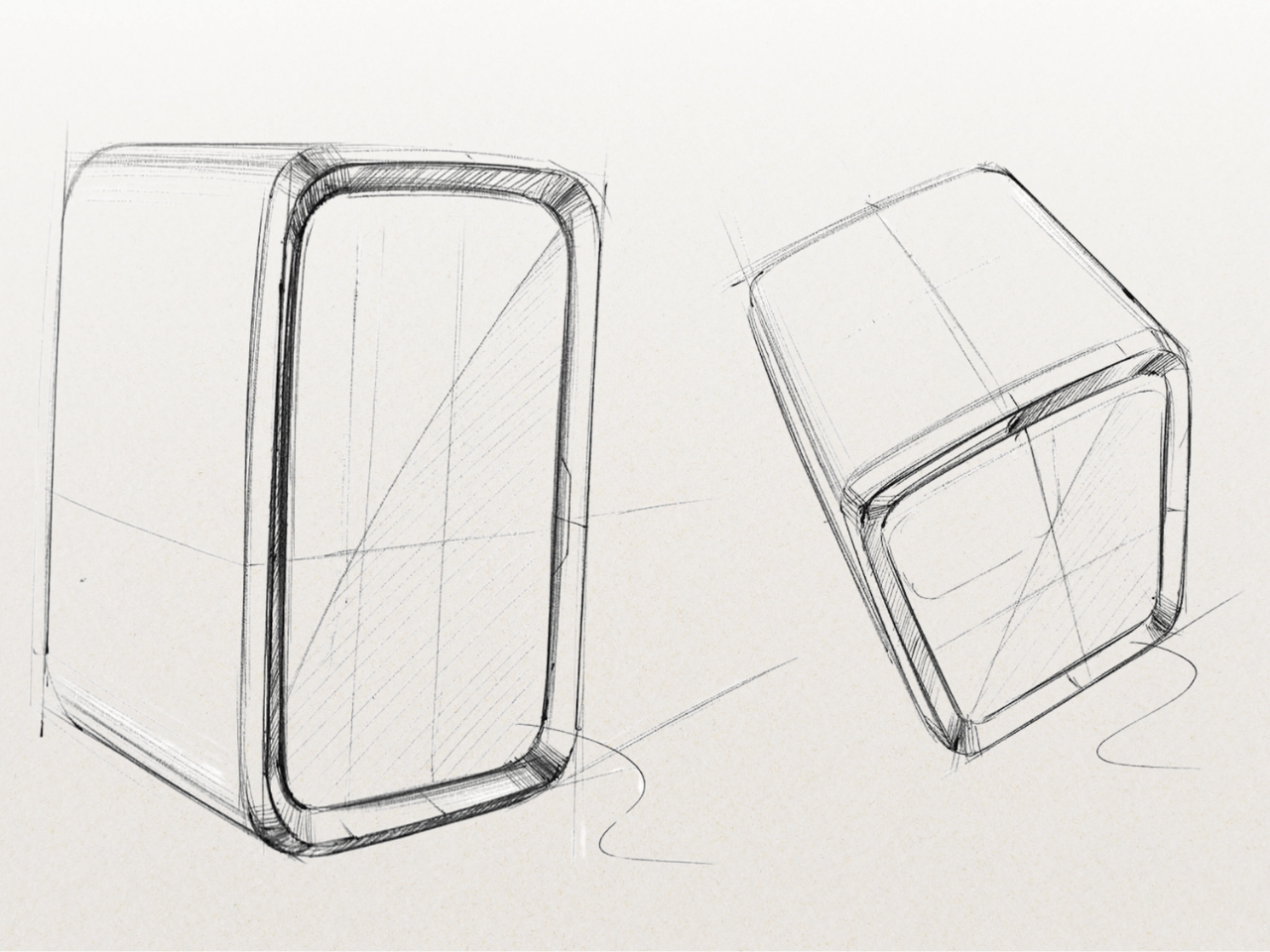

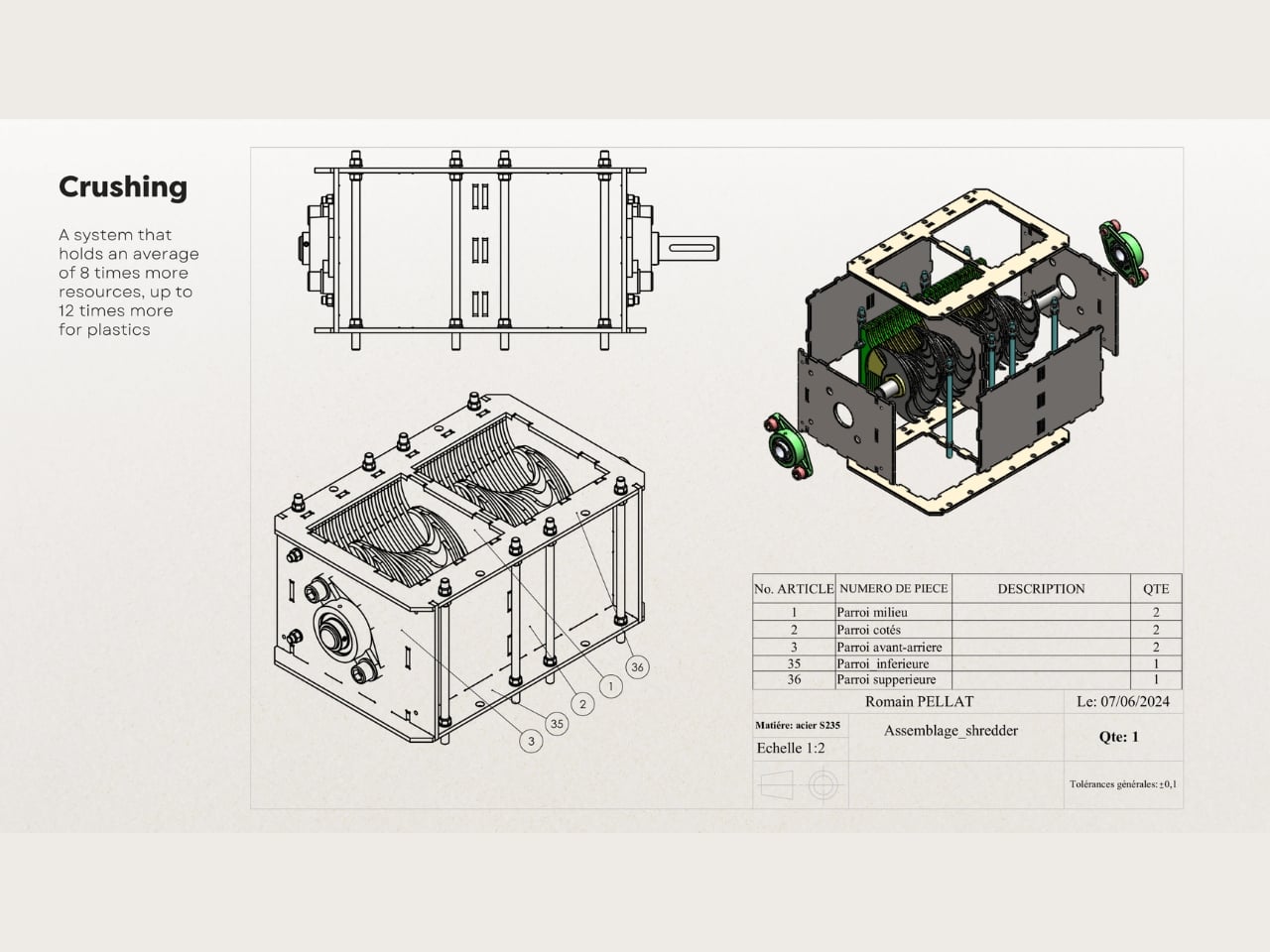

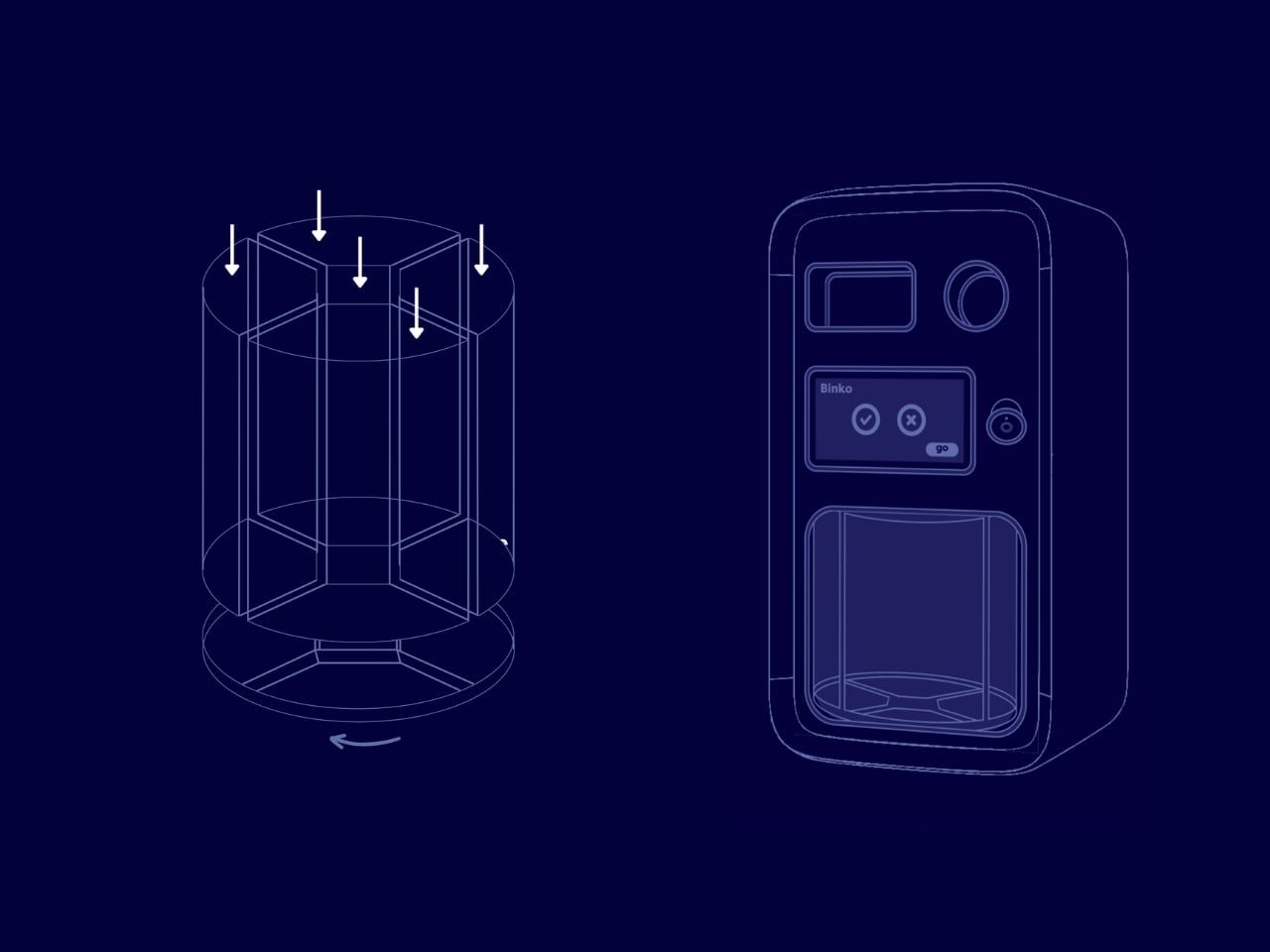

The concept device looks like a vendo machine but instead of it giving you your drink or snack of choice, you feed it your garbage. The machine and the accompanying app should be able to recognize more than 2.6 million waste items. Then it will compress or crush the garbage into small pieces and is able to hold an average of 8 times more resources. The system is able to sort it into one of the 7 transparent compartments that can be adapted according to location.

The app will be the first to launch and it can immediately help people into recognizing how to sort their garbage using the AI-powered photo recognition process. It also gives you a map of nearby recycling bins and even reminds you to take out your trash. That in itself is useful even as Binko will probably take more time to be created.

The post AI-powered machine concept helps you sort and dispose of waste properly first appeared on Yanko Design.