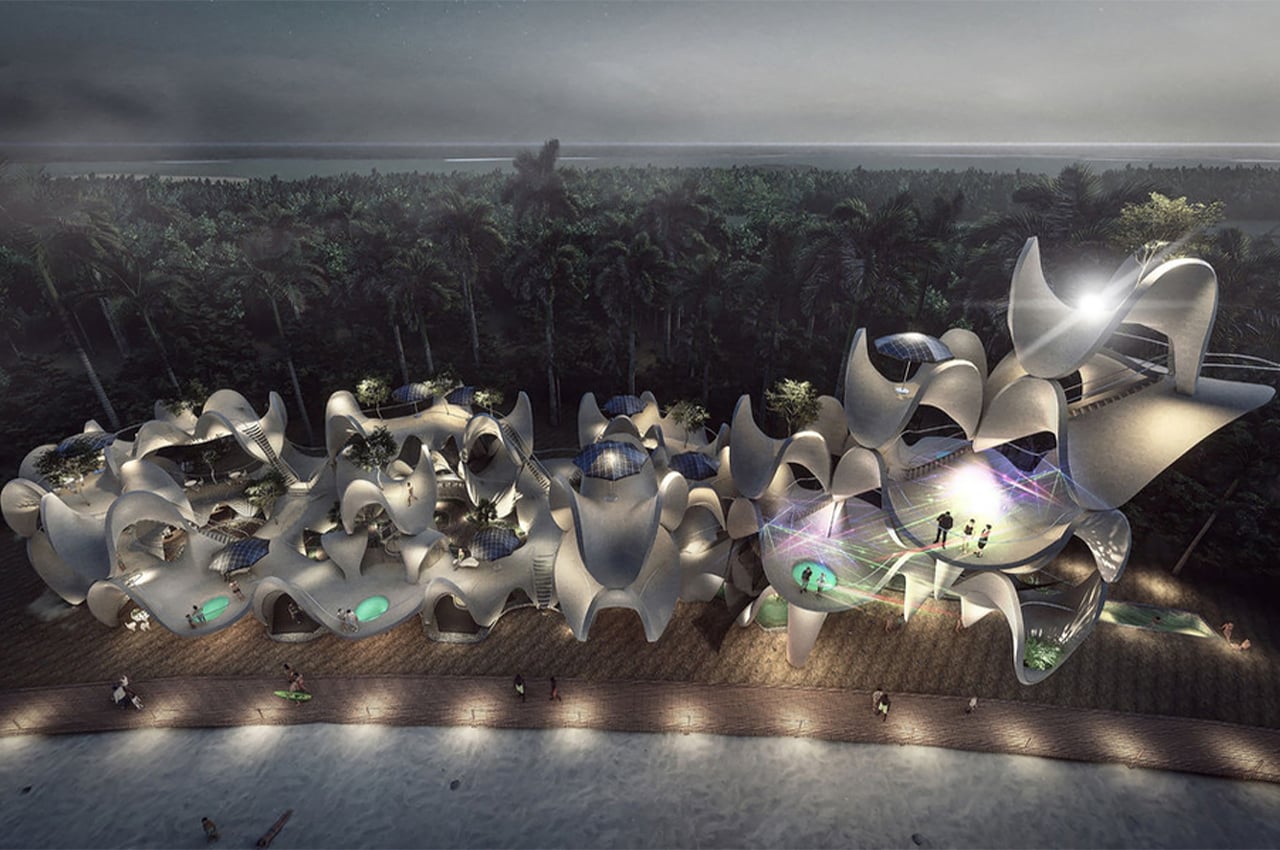

ARCspace began as a pilot program as a potential solution to the extreme homelessness crisis in L.A. but has now grown into a range of several accommodation options ranging from 160 to 10,000 square feet.

The construction industry is responsible for 28% of the global emissions and construction-related industries like glass and cement add another 10% to the global emissions. If you think about it 38% of the world’s emissions is a lot and if we find sustainable solutions for the construction industry, we can make a large positive impact rather quickly because it will ripple out to related industries and therefore we can scale up sustainable development faster. I know it is an unlikely approach, but to make the biggest dent when solving a problem we have to start by untangling the biggest knot! ARCspace is a modular architecture firm that is constantly creating innovative designs and material development to do its part in curbing the emissions for their industry using sustainable, affordable, prefabricated homes.

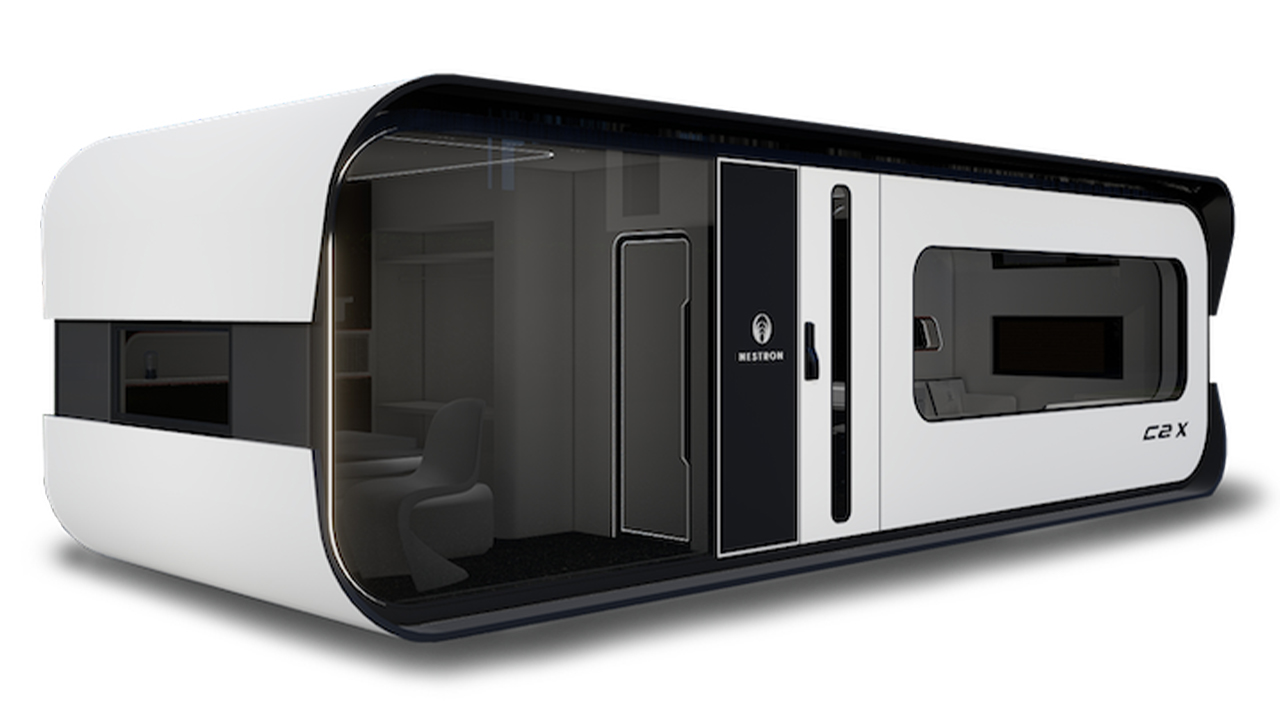

Fun Fact: ARCspace is a division of Sustainable Building Council Ltd., located in the Los Angeles Cleantech Corridor so as a parent company, the goal of Sustainable Building Council Ltd. is to bring together experts in construction, architectural design, engineering, building, environmentalism, and innovative technology to address housing needs around the world. The mission is to work together to create efficient, cost-efficient, and long-lasting housing. It began as a pilot program as a potential solution to the extreme homelessness crisis in L.A. but has now grown into a range of several accommodation options ranging from 160 to 10,000 square feet. All structures are prefabricated for highly efficient and quick builds which reduce emissions and minimizes waste. ARCspace reports the buildings are “spec-built from the ground up in 40-60% less time and cost than traditional construction.”

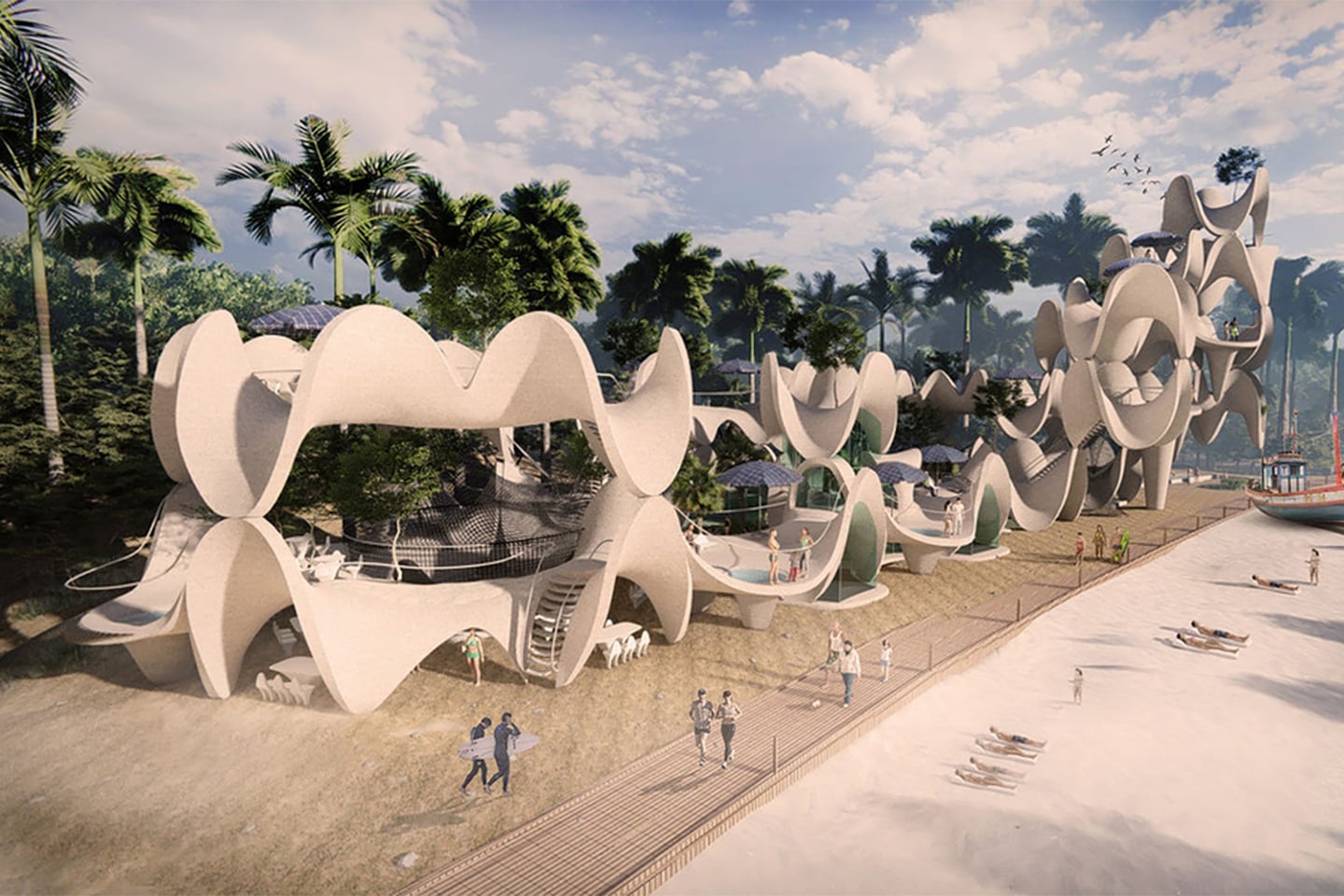

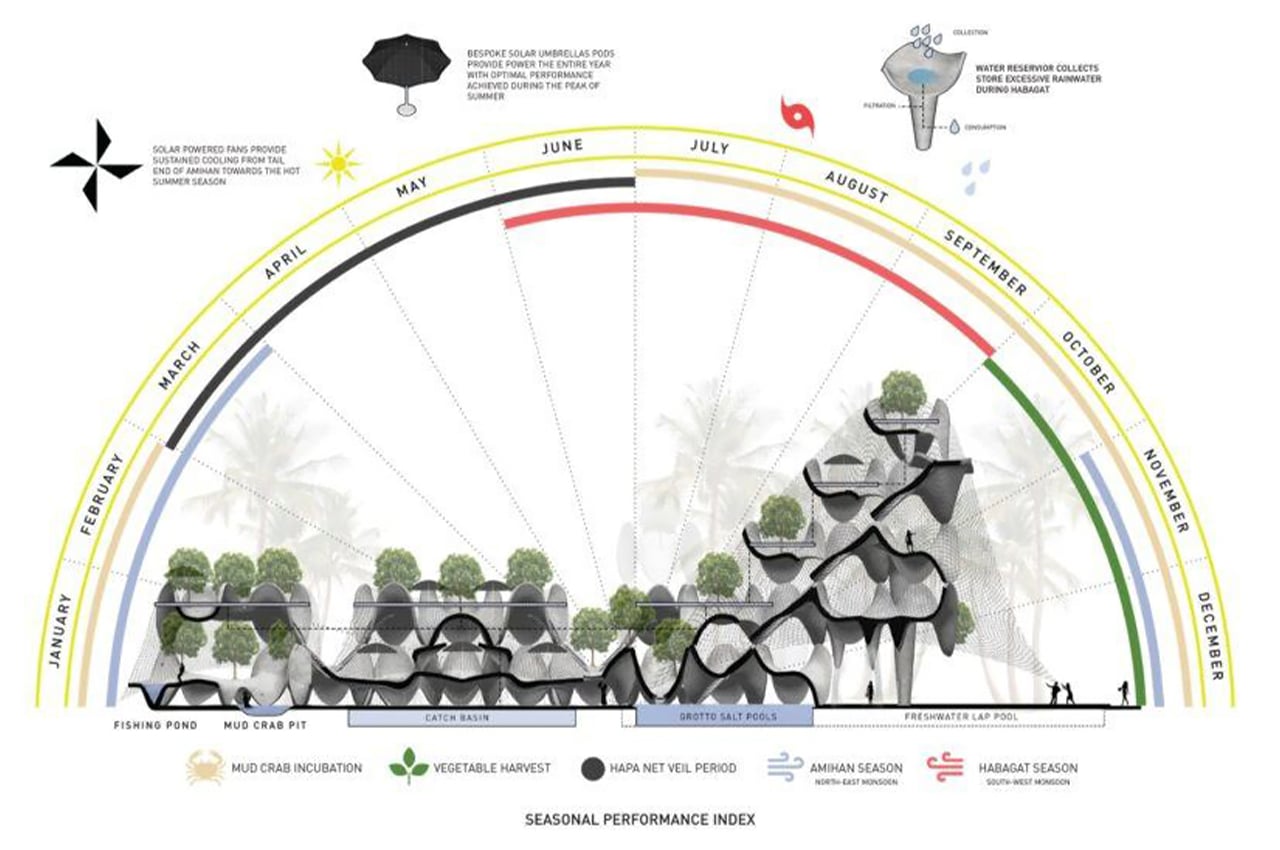

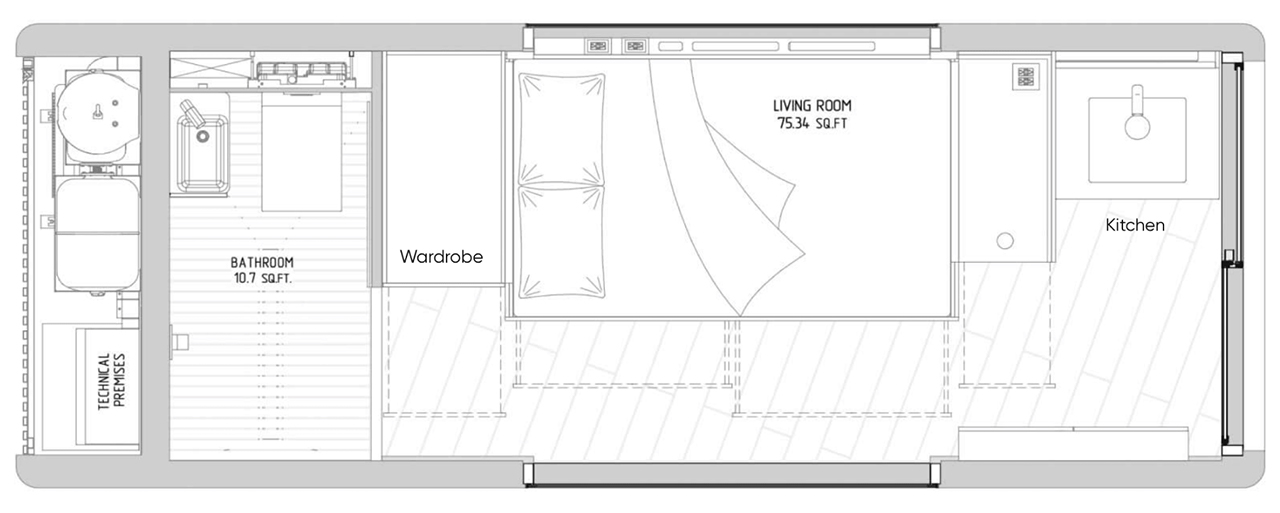

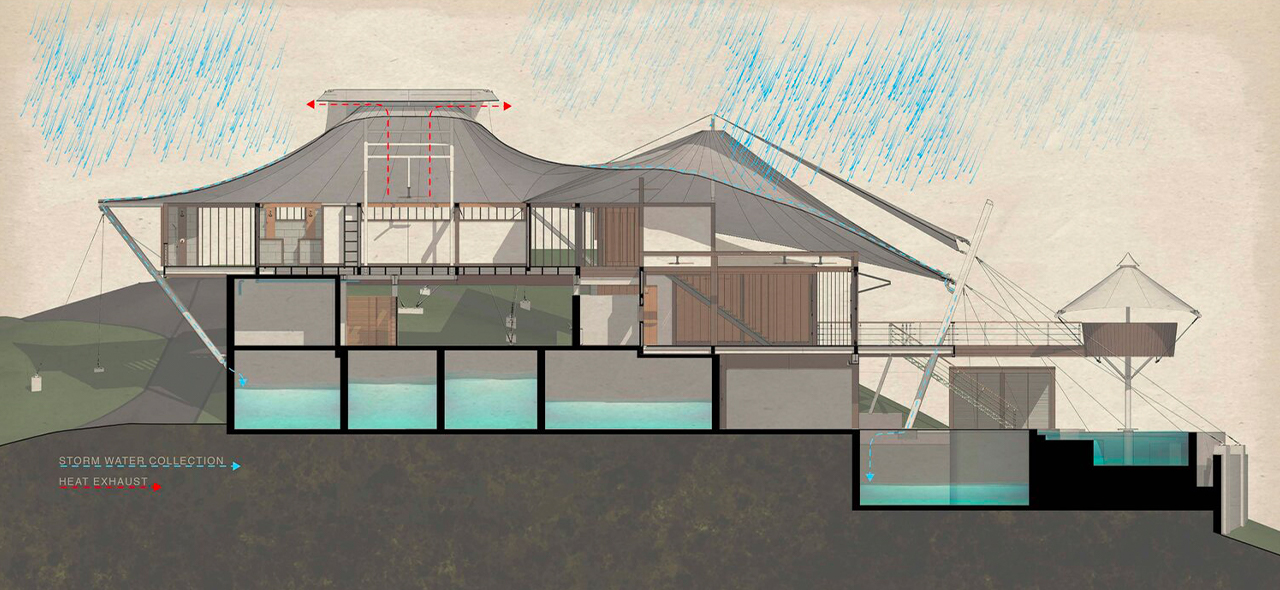

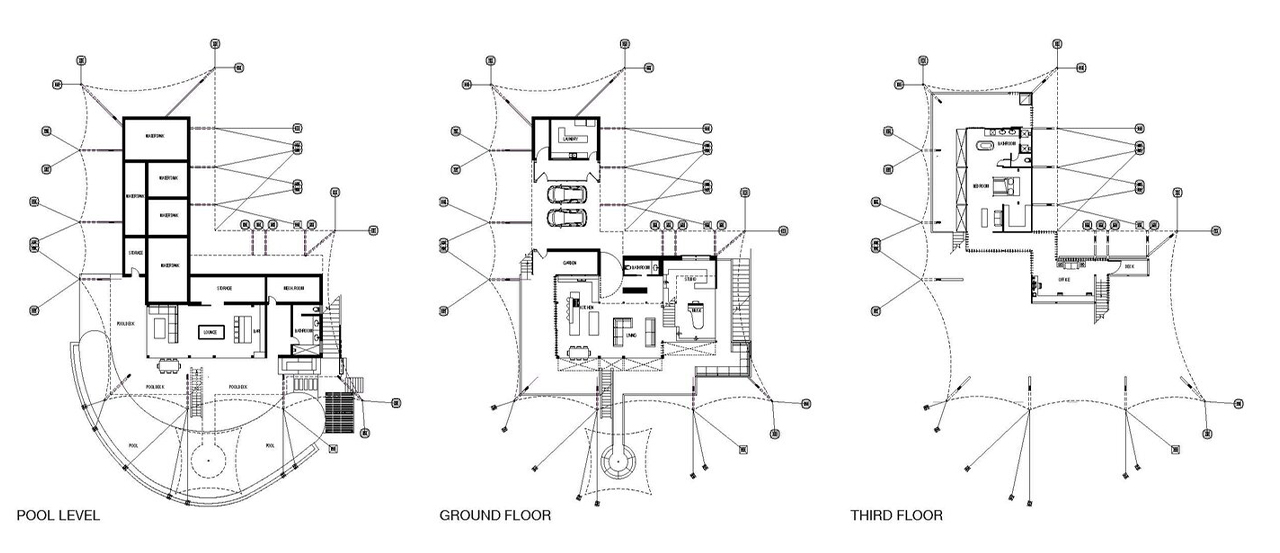

Residents can fully customize their tiny homes or even scale up to the size of traditional homes and have a huge range of interior design details to choose from including optional elements that provide off-grid power and water. Some homes feature self-contained atmospheric water generators called Hydropanels that are grid-independent and pull a few liters of drinking water out of the air each day. Affordable solar panels are another add-on option, however, the primary supply still comes from onsite plumbing and electrical systems. Units can be linked end to end or stacked up to four units high with stairways connecting each unit.

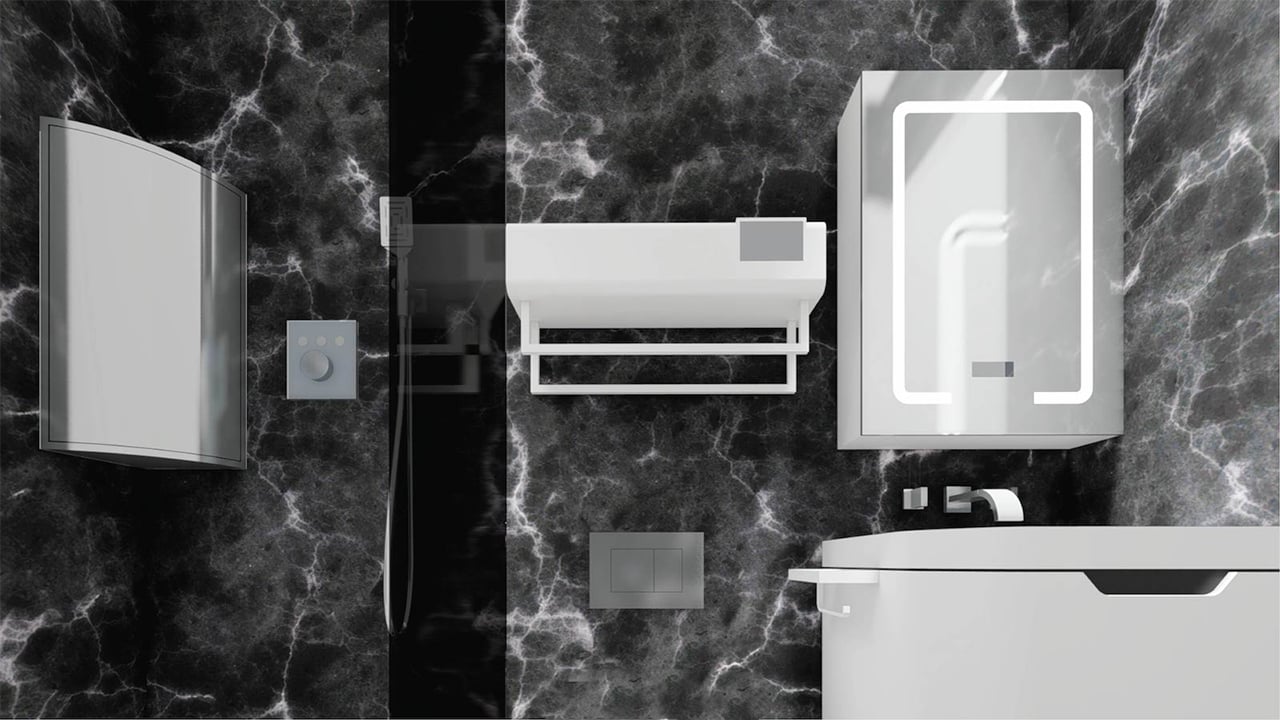

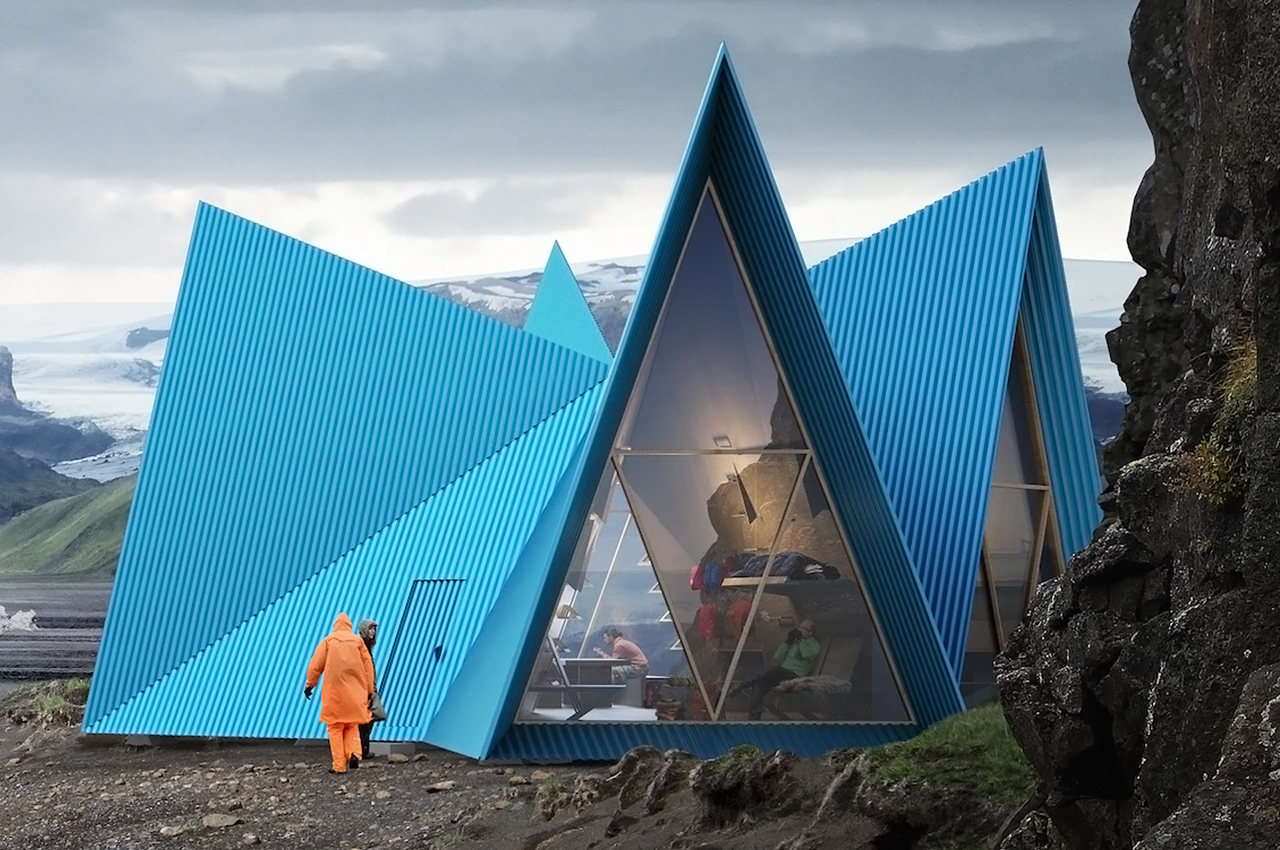

In addition to avoiding toxins in construction, ARCspace puts a focus on smart home features that are energy-efficient and healthy. The company employs a variety of sustainable technologies such as environmentally friendly, vegetable-based spray foam insulation and specialized window coatings that keep excessive heat out while allowing natural light in. It also uses recycled materials throughout, including for decking and outer cladding. For temporary work sites or emergency housing needs, impermanent foundations mean the units can be relocated with minimal site impact. They can also be set up in as little as 24 hours once onsite with a small team using cranes to stack modules then following up with window installations.

High-grade steel is the primary material selected for durability and seismic safety requirements in California. Steel also makes the prefab homes resilient in the face of high winds while also being highly fire-resistant which is another climate crisis-induced problem in California. It is also easier to maintain and long-lasting because steel won’t succumb to termites. Finally, it can be easily reused or recycled! “We do not utilize or work with any form of used containers, not even 1-trip containers (those only used one time). Shipping containers are manufactured with materials known to cause cancer such as LED paint, DDT wood flooring, and often have insecticide coatings, etc,” says the team as they point out how they are different from shipping containers.

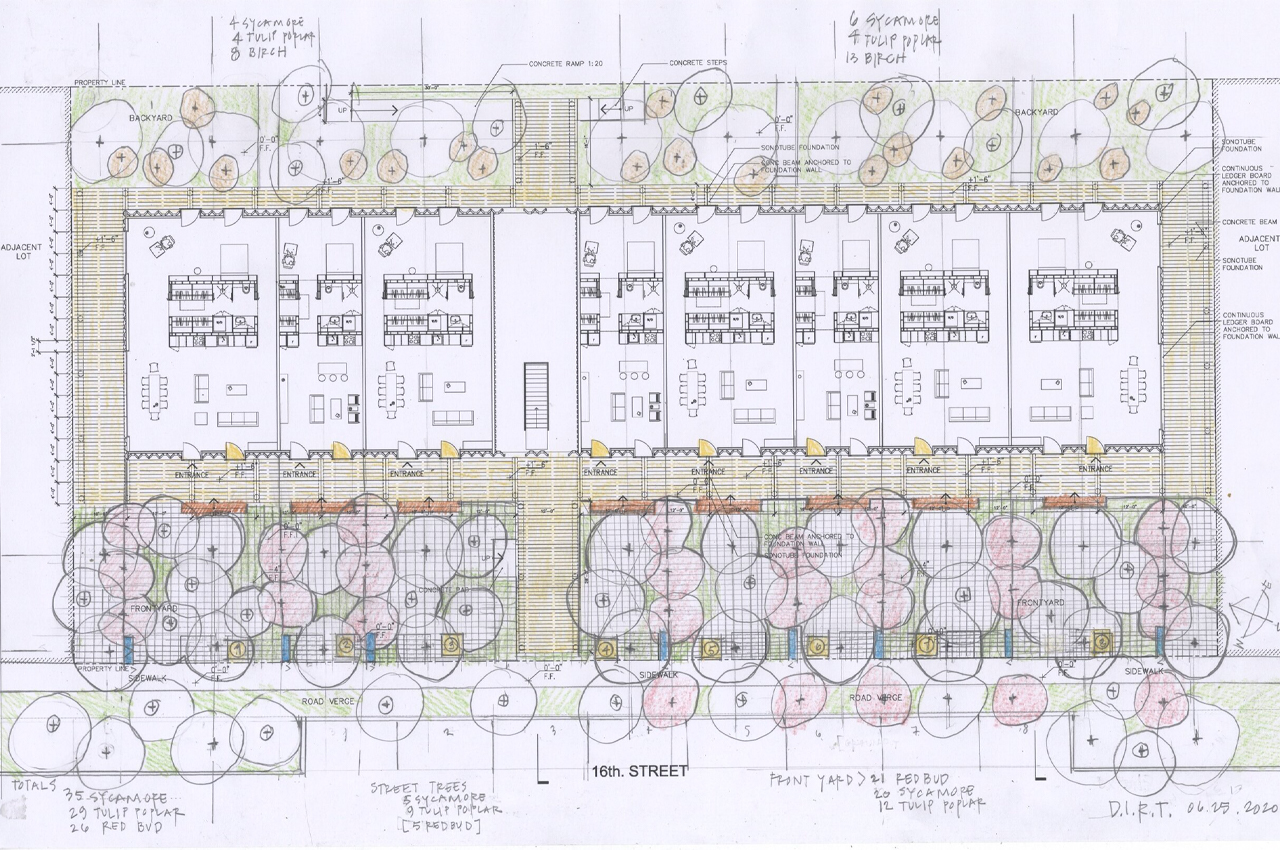

The company said, “Last year, ARCspace collaborated with Habitat for Humanity to create an Emergency Shelter Project in the San Francisco Bay area using America’s first prefabricated foundation and worked with local trade schools to help prepare a new workforce with an understanding of emerging sustainable building technology.” This quick-build housing showed the potential for ARCspace to provide affordable housing but also served as inspiration for those considering a career in green design. ARCscpace is working on changing buildings, landscapes, urban designs, and policies that make cities and living cleaner, more efficient, more beautiful, and more equitable for their citizens.

Designer: ARCspace

The construction industry is responsible for 28% of the global emissions and construction-related industries like glass and cement add another 10% to the global emissions. If you think about it 38% of the world’s emissions is a lot and if we find sustainable solutions for the construction industry, we can make a large positive impact rather quickly because it will ripple out to related industries and therefore we can scale up sustainable development faster. I know it is an unlikely approach, but to make the biggest dent when solving a problem we have to start by untangling the biggest knot! ARCspace is a modular architecture firm that is constantly creating innovative designs and material development to do its part in curbing the emissions for their industry using sustainable, affordable, prefabricated homes.

Fun Fact: ARCspace is a division of Sustainable Building Council Ltd., located in the Los Angeles Cleantech Corridor so as a parent company, the goal of Sustainable Building Council Ltd. is to bring together experts in construction, architectural design, engineering, building, environmentalism, and innovative technology to address housing needs around the world. The mission is to work together to create efficient, cost-efficient, and long-lasting housing. It began as a pilot program as a potential solution to the extreme homelessness crisis in L.A. but has now grown into a range of several accommodation options ranging from 160 to 10,000 square feet. All structures are prefabricated for highly efficient and quick builds which reduce emissions and minimizes waste. ARCspace reports the buildings are “spec-built from the ground up in 40-60% less time and cost than traditional construction.”

High-grade steel is the primary material selected for durability and seismic safety requirements in California. Steel also makes the prefab homes resilient in the face of high winds while also being highly fire-resistant which is another climate crisis-induced problem in California. It is also easier to maintain and long-lasting because steel won’t succumb to termites. Finally, it can be easily reused or recycled! “We do not utilize or work with any form of used containers, not even 1-trip containers (those only used one time). Shipping containers are manufactured with materials known to cause cancer such as LED paint, DDT wood flooring, and often have insecticide coatings, etc,” says the team as they point out how they are different from shipping containers.

Residents can fully customize their tiny homes or even scale up to the size of traditional homes and have a huge range of interior design details to choose from including optional elements that provide off-grid power and water. Some homes feature self-contained atmospheric water generators called Hydropanels that are grid-independent and pull a few liters of drinking water out of the air each day. Affordable solar panels are another add-on option, however, the primary supply still comes from onsite plumbing and electrical systems. Units can be linked end to end or stacked up to four units high with stairways connecting each unit.

In addition to avoiding toxins in construction, ARCspace puts a focus on smart home features that are energy-efficient and healthy. The company employs a variety of sustainable technologies such as environmentally friendly, vegetable-based spray foam insulation and specialized window coatings that keep excessive heat out while allowing natural light in. It also uses recycled materials throughout, including for decking and outer cladding. For temporary work sites or emergency housing needs, impermanent foundations mean the units can be relocated with minimal site impact. They can also be set up in as little as 24 hours once onsite with a small team using cranes to stack modules then following up with window installations.

The company said, “Last year, ARCspace collaborated with Habitat for Humanity to create an Emergency Shelter Project in the San Francisco Bay area using America’s first prefabricated foundation and worked with local trade schools to help prepare a new workforce with an understanding of emerging sustainable building technology.” This quick-build housing showed the potential for ARCspace to provide affordable housing but also served as inspiration for those considering a career in green design. ARCscpace is working on changing buildings, landscapes, urban designs, and policies that make cities and living in the cleaner, more efficient, more beautiful, and more equitable for their citizens.

Designer: ARCspace