Picture this: instead of manufacturing your next coffee cup, what if you could just grow it? That’s the beautifully simple yet radical idea behind The Gourd Project, an ongoing exploration by Brooklyn-based CRÈME Architecture and Design that’s turning heads in the sustainable design world.

Here’s the problem they’re tackling. Back in 2006, Starbucks alone used 2.6 billion cups at their stores. Each paper cup produces 0.24 pounds of CO2 emissions during manufacturing, and here’s the kicker: only 0.25% actually get recycled after disposal. We’ve been stuck in this wasteful cycle for decades, bouncing between plastic, paper, and ceramic options that all come with their own environmental baggage. CRÈME decided to ask a different question entirely: what if nature didn’t just provide the material, but also handled the manufacturing process?

Designer: CRÈME Architecture and Design

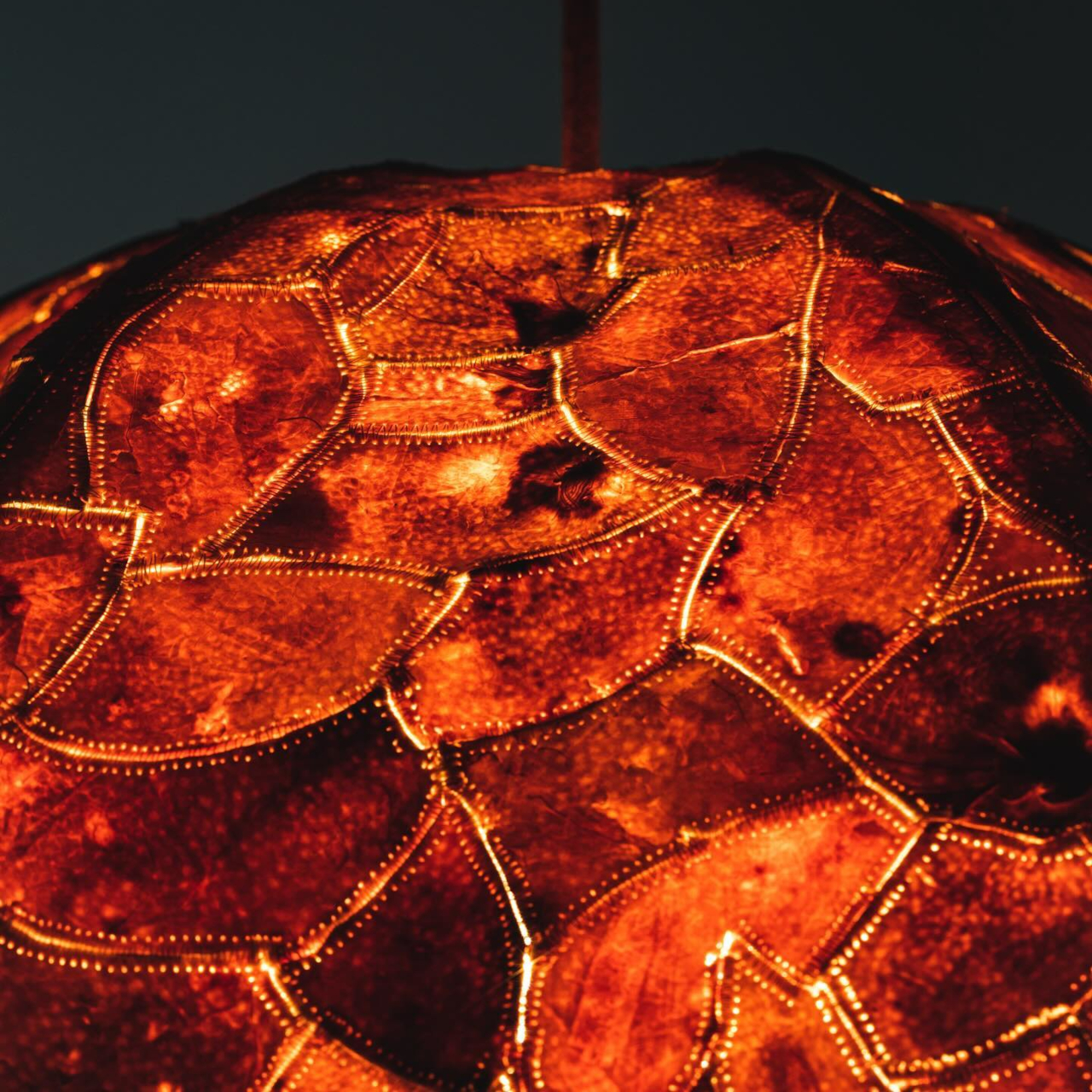

Enter the humble gourd. These fast-growing plants have been cultivated by humans for thousands of years, prized for their robust fruits that develop strong outer skins and fibrous inner flesh. Once dried, gourds become naturally watertight, which is why our ancestors used them as cups and containers long before Tupperware was a thing. CRÈME, led by designer Jun Aizaki, looked at this ancient practice and thought: we can do something with this.

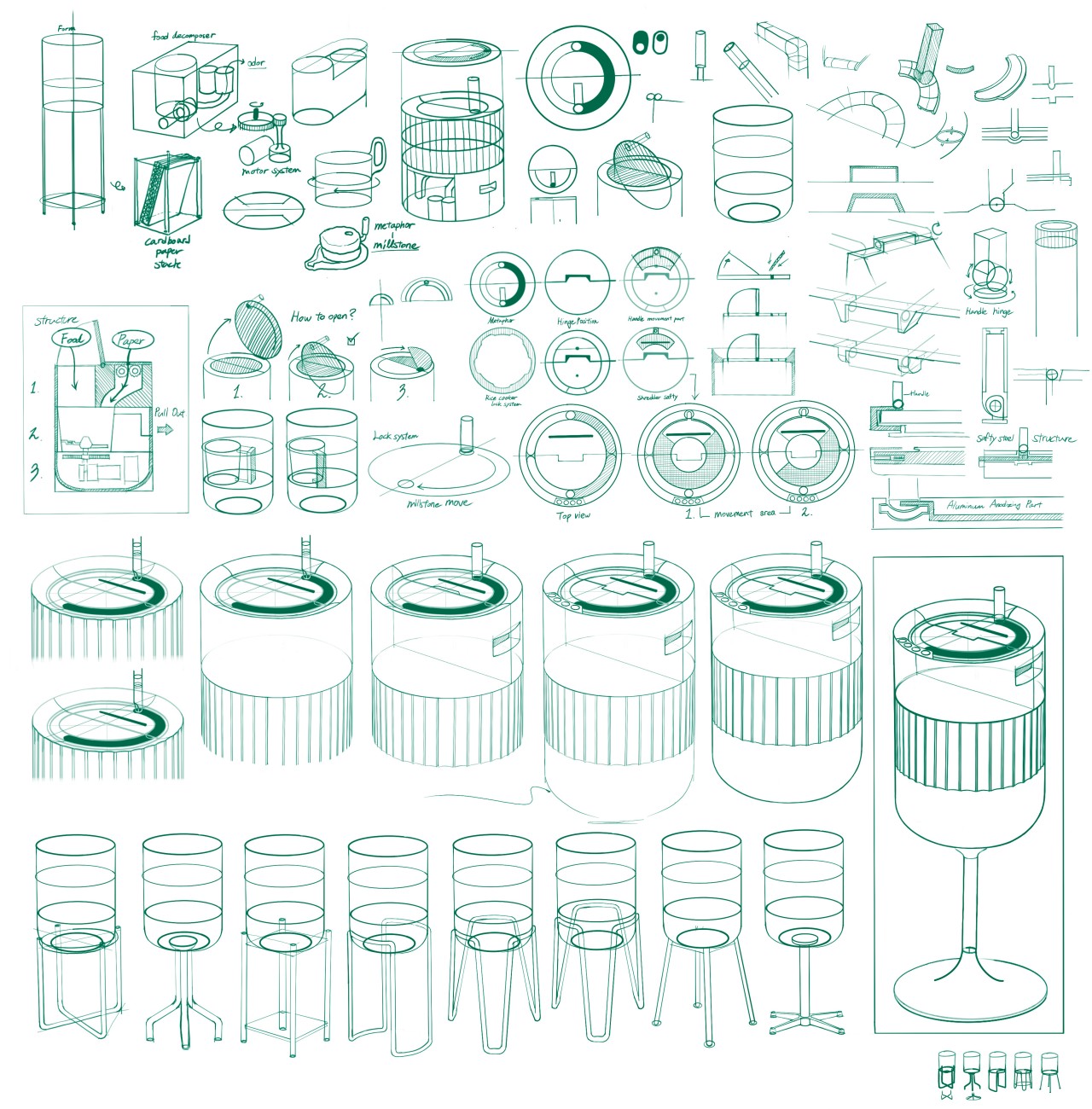

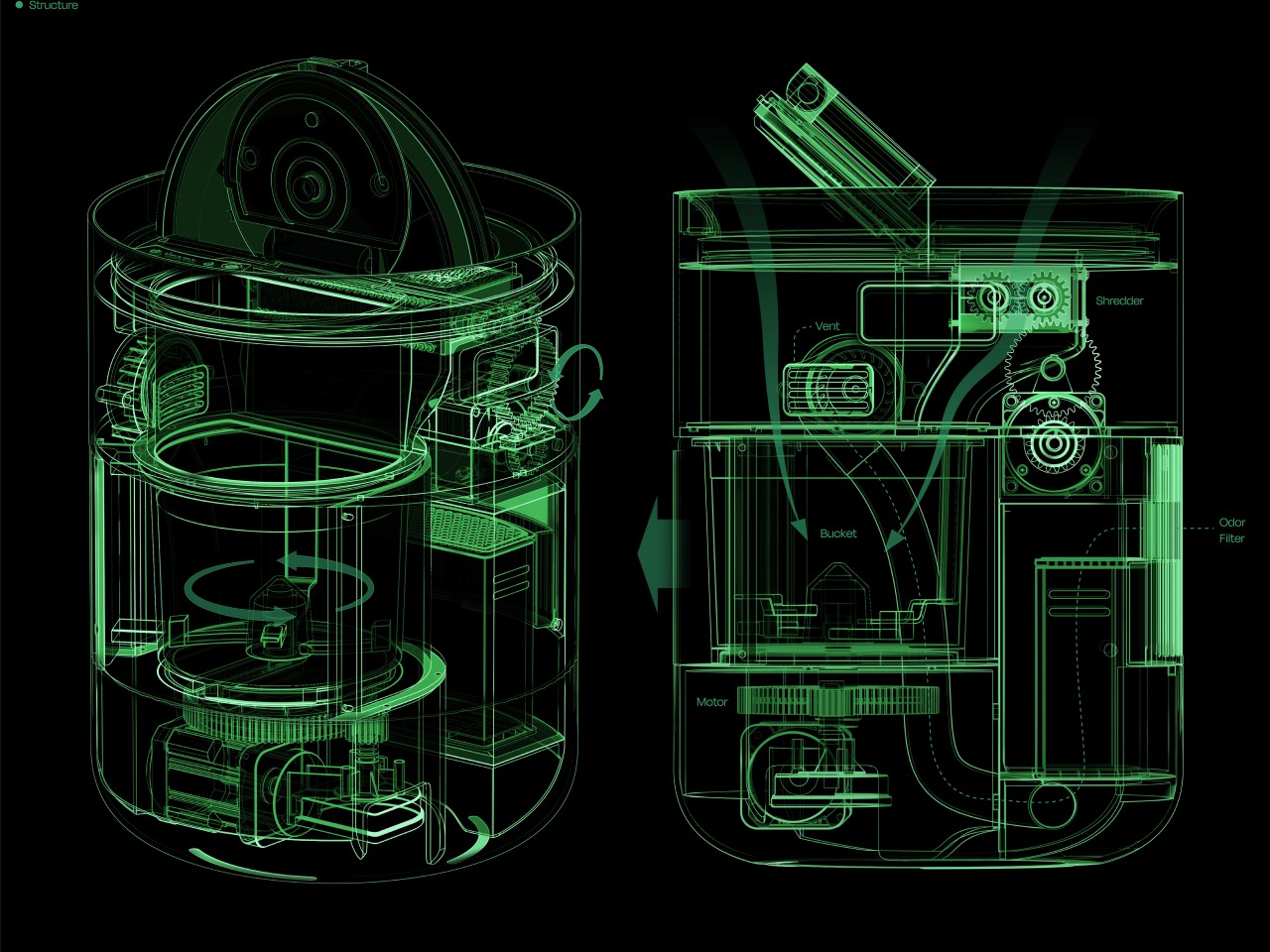

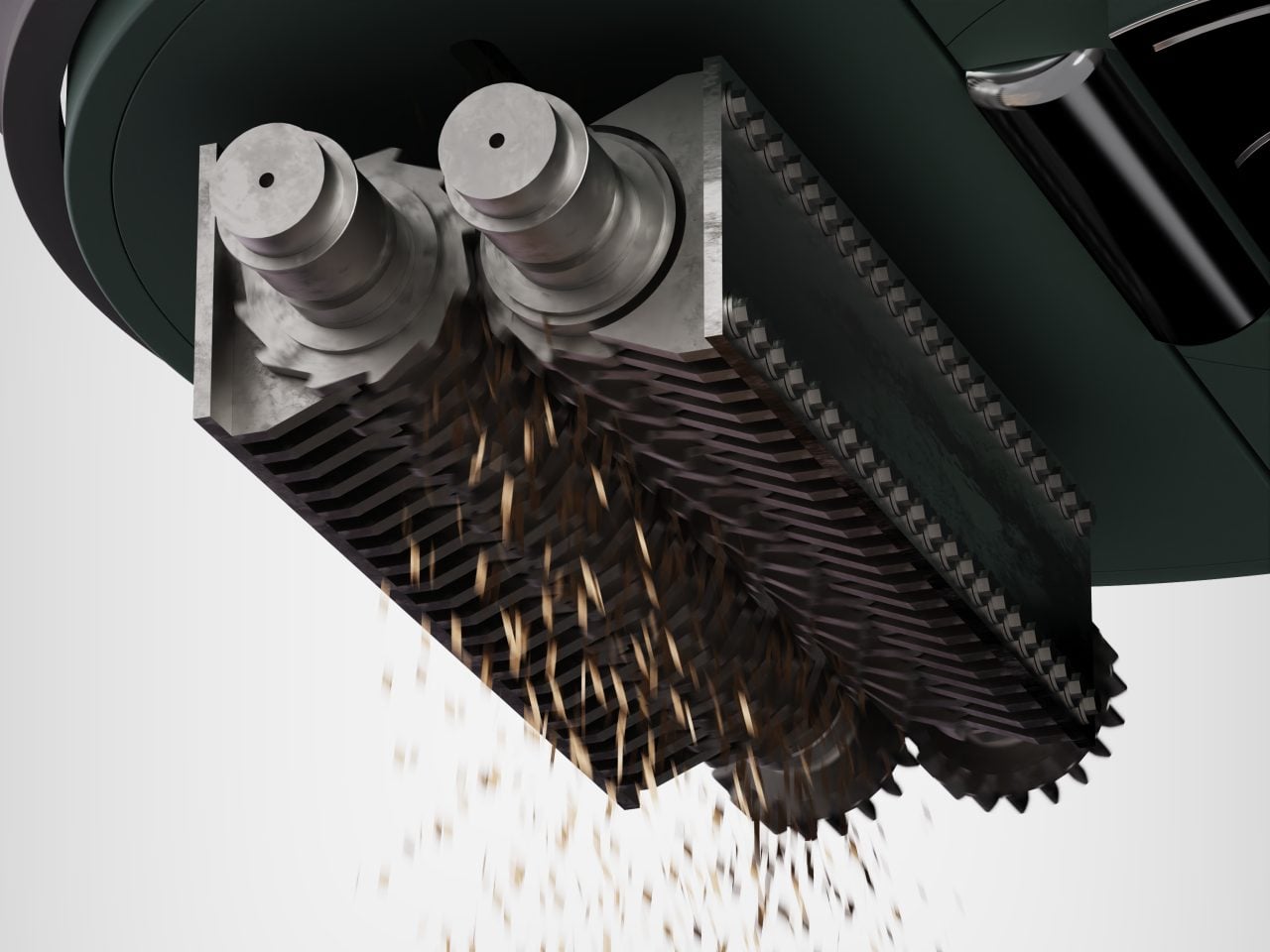

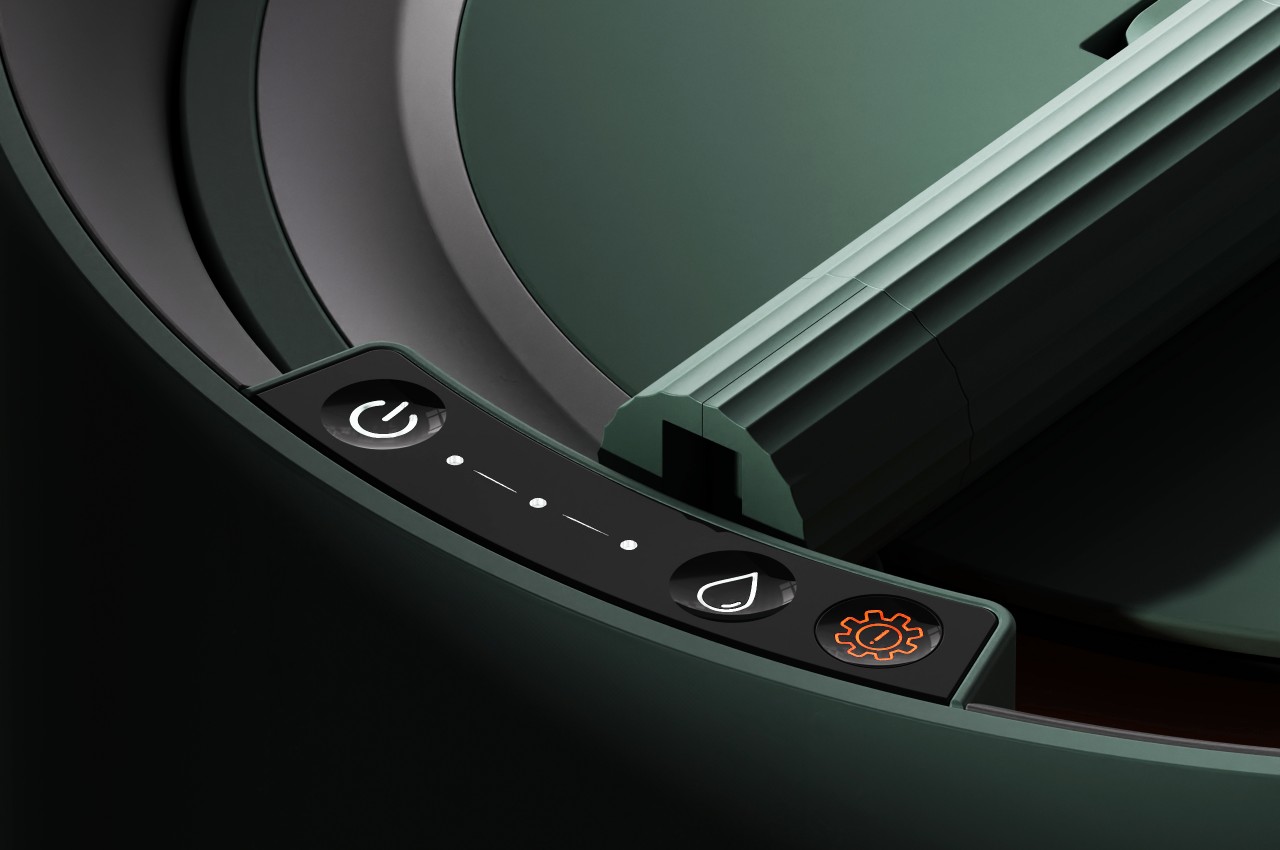

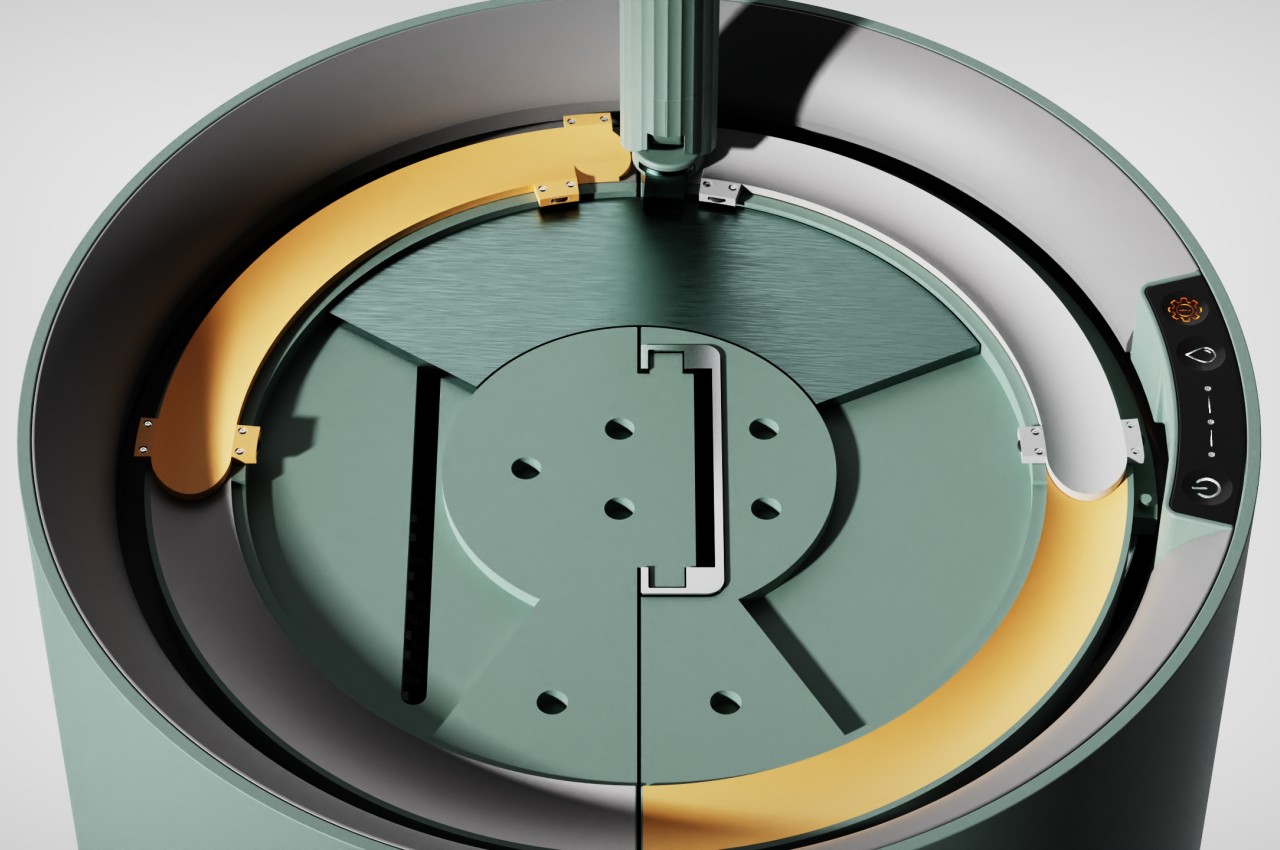

But here’s where it gets really cool. The studio isn’t just hollowing out gourds and calling it a day. They’re using 3D-printed molds to actually shape the gourds as they grow, training them into specific forms like cups and flasks. Think of it as botanical architecture. You place the mold around the young fruit, and nature does the rest, filling the shape while it grows on the vine. The result? Vessels that are 100% biodegradable, manufactured using only sun and water, and look genuinely striking sitting on your shelf.

The project started small, with a few gourds grown in a backyard. But CRÈME has since scaled up production to a farm, with plans to eventually move operations indoors to better control for variables like pests and weather conditions. The entire production cycle currently takes about six weeks, and while the team is working to streamline that timeline, it’s still remarkably efficient compared to traditional manufacturing processes that involve mining, refining, molding, and shipping materials around the globe.

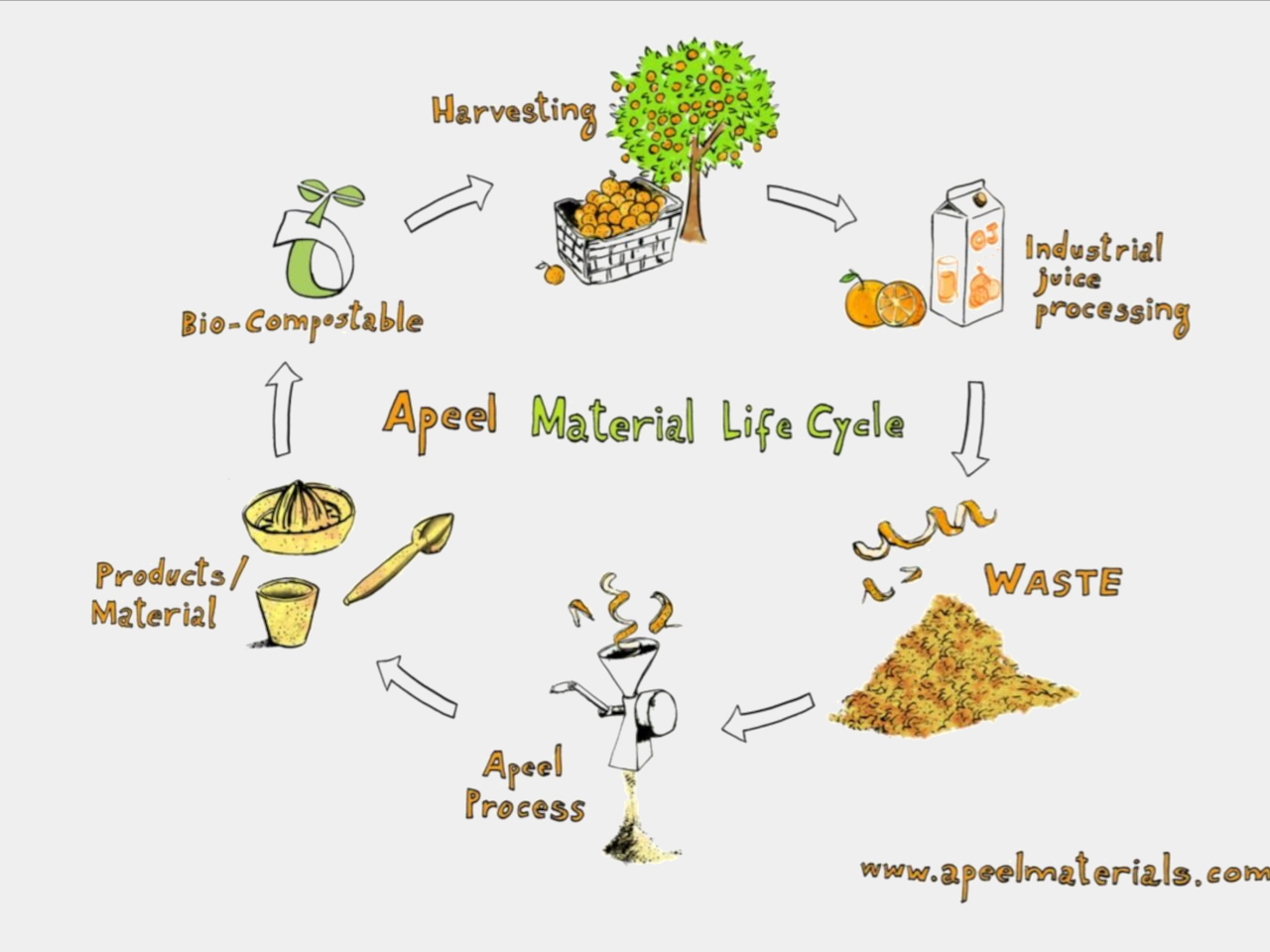

Each gourd vessel can be reused between three to six times before it starts to break down. At that point, you’re not adding to a landfill or hoping it makes it to a recycling facility. You just toss it in with your food waste and let it compost naturally. It’s a genuine cradle-to-cradle approach, where the end of one cup’s life becomes the beginning of nutrients for the next season’s growth.

The design world has noticed. The Gourd Project earned a finalist mention at the NYCxDesign awards and has been featured in major publications like Dezeen, Fast Company, and NowThis News. It’s easy to see why. In an era where greenwashing is rampant and “sustainable” often just means “slightly less terrible,” here’s a project that actually reimagines the entire system from the ground up, literally.

What makes this particularly exciting is how it challenges our assumptions about design and manufacturing. We’re so conditioned to think of products as things we make, things we control from start to finish in factories. The Gourd Project flips that script. It asks us to collaborate with nature, to work with biological processes instead of against them. The designers provide the framework, the blueprint. The plant does the actual building.

Will we all be sipping our lattes from gourds next year? Probably not. CRÈME is still refining the process and working toward a consumer launch. But that’s almost beside the point. The Gourd Project proves that radical sustainability doesn’t have to mean sacrifice or hairshirt aesthetics. These vessels are genuinely beautiful, with organic variations that make each one unique. They represent a fundamentally different way of thinking about the objects we use every day.

The post This Studio Grows Coffee Cups From Gourds first appeared on Yanko Design.