Luxury and cutting-edge audio design converge in the Marantz Grand Horizon and its smaller counterpart, the Horizon. These speakers merge visual sophistication, material innovation, and immersive sound quality, setting a new standard in high-end audio. Reflecting Marantz’s legacy in audio craftsmanship, they combine advanced technology with artistic design for a truly immersive experience.

Designer: Marantz

The Grand Horizon transforms its sound and visual presence by redefining what a speaker can be. The iconic porthole motif, a core element of Marantz’s design language for decades, is embraced in this new offering to deliver a listening experience that is as visually inspiring as it is acoustically impactful.

Model Distinctions: Horizon vs. Grand Horizon

The Marantz Horizon is the smaller of the two models, featuring a 310-watt FTC-rated power output (745 watts peak). It includes a driver configuration of one 165mm subwoofer, two 25mm silk-dome tweeters, and three 50mm full-range drivers. With dimensions of 364 x 210 x 387.5mm (14.33 x 8.27 x 15.26 inches), it is priced at $3,500.

In contrast, the larger model, the Marantz Grand Horizon, boasts a 370-watt FTC-rated power output (860 watts peak). Its driver configuration comprises one 200-mm subwoofer, three 25-mm tweeters, and four 76-mm midrange drivers. Measuring 493 x 255 x 529.2mm (19.41 x 10.04 x 20.83 inches), it is priced at $5,500.

Both models share features such as the circular design, HEOS platform integration, and Marantz Mirage DSP. However, the Grand Horizon is larger and more powerful and offers a more advanced driver configuration, providing a richer audio experience.

Sophisticated Circular Design and Materials

With its circular design, the Grand Horizon draws immediate attention. Unlike most rectangular wireless speakers, its sculptural form makes a bold visual statement in any room. Thesphere’s symmetry, paired with premium materials like natural marble and sustainable fabrics, transforms it into a luxurious art piece that delivers world-class sound.

Wrapped in Marantz’s Radiance 360 Seamless Ecofiber, made from recycled ocean plastics, the Grand Horizon is visually stunning and eco-conscious. The fabric’s intricate texture enhances its aesthetic and diffuses sound, ensuring optimal acoustic performance. This recycled Ecofiber underscores Marantz’s commitment to sustainability while retaining an opulent feel. The fabric’s texture contrasts with the smooth metal accents that form the porthole ring, creating a tactile, luxurious experience.

The marble base, available in different colors to complement each fabric finish, adds a touch of natural elegance. Solid and stable, it elevates the speaker beyond a mere device; it becomes a significant decor element. Each marble base is sculpted to be smooth and substantial, grounding the spherical form and creating an interplay between nature and technology.

Powerful Audio Performance

With its striking design, the Marantz Grand Horizon also delivers serious audio performance. With a 200mm subwoofer, three 25mm tweeters, and four 76mm midrange drivers, it offers deep bass, clear highs, and immersive midrange. This driver array is key to producing the full-bodied sound Marantz is known for—rich, warm, and incredibly lifelike.

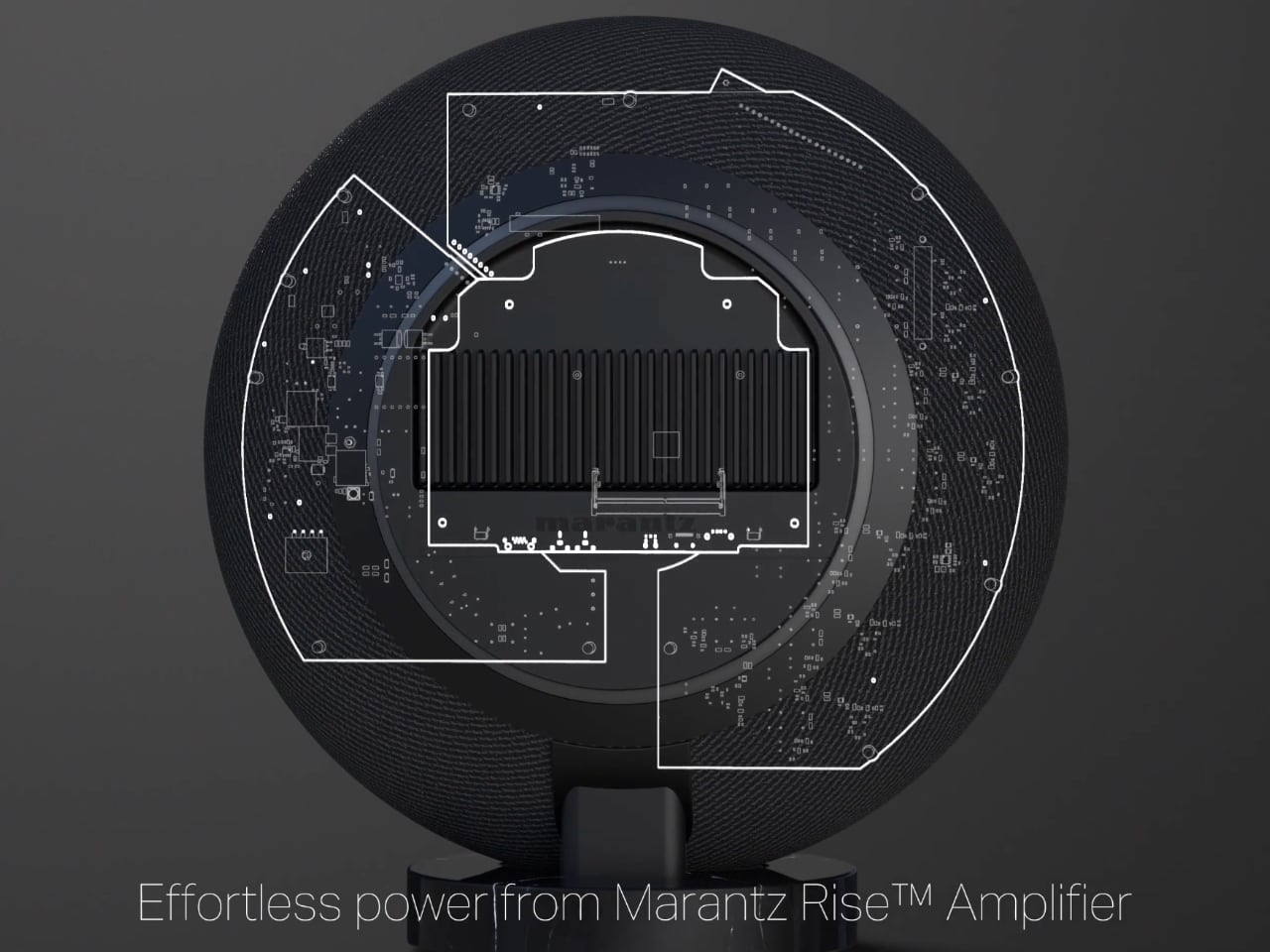

The Grand Horizon’s 370-watt amplification is powered by Marantz’s Rise amplification technology, featuring GaN FETs for high power efficiency and reduced thermal distortion. It delivers sound as close as possible to the original recording. Even at high volumes, the Grand Horizon remains poised, delivering uncompromised sound.

A key feature is its ability to adjust and fine-tune the audio experience through Marantz Mirage DSP. Users can personalize the sound by adjusting clarity, warmth, and spaciousness to their preference, ensuring each listening session meets unique tastes. The Sound Master mode offers a refined experience curated by Marantz Sound Master Yoshinori Ogata, bringing out the best in any track.

Interactive and Customizable Design Features

The use of light and motion elevates the Grand Horizon beyond a mere object. The AuraControl system incorporates concealed LEDs that respond to proximity. As someone approaches the speaker, the lights subtly activate, giving the impression that it comes to life, adding an interactive component that feels almost personable. This thoughtful addition sets it apart from other luxury speakers.

This light ring also serves as a touch-sensitive interface, allowing users to adjust the volume by simply running their hand along the edge of the gold ring. This feature feels natural and almost ceremonial—a tactile connection to the sound. It transforms the speaker from a mere device into an experience.

The base, made from natural marble, enhances the speaker’s stature. Different stone types for each colorway—from Midnight Sky’s dark elegance to Marantz Champagne’s warmth—allow the speakers to adapt to various living spaces. They are designed to blend seamlessly into both modern and classic interiors.

Comprehensive Connectivity and Multi-Room Integration

With advanced connectivity features, the Marantz Grand Horizon is as versatile as it is beautiful. The speaker supports Bluetooth, Wi-Fi, AirPlay 2, and Spotify Connect, providing direct access to streaming services such as Amazon Music, Deezer, and TIDAL. Whether it’s a quick Bluetooth pairing for an impromptu playlist or immersing yourself in a high-resolution stream, Marantz ensures accessing your favorite content is effortless.

Physical inputs add flexibility, with stereo RCA, optical, HDMI eARC, and USB-C available to connect to various sources. The HDMI eARC input also supports Dolby decoding, allowing users to experience the nuance of Dolby Atmos content when connected to a compatible display, expanding its use beyond music to home cinema.

Through the HEOS multi-room audio platform, the Grand Horizon can integrate into a broader home audio setup. You can easily sync multiple speakers throughout the home, playing synchronized music in each room or creating unique sound environments in different spaces—all managed through the HEOS app. Its ability to pair with another unit also allows for a true stereo experience, transforming any room into a high-fidelity listening space.

Aesthetics for Any Space

Available in three finishes—Midnight Sky, Moon Ray, and Marantz Champagne—the Grand Horizon and its smaller counterpart, the Horizon, provide a distinct visual identity. Midnight Sky is dark and sleek, exuding sophisticated elegance for minimalist or modernist settings. Moon Ray, by contrast, is a bright, off-white finish that brings a subtle sparkle, ideal for spaces that value lightness and openness. Finally, Marantz Champagne adds warmth and luxurious charm, making it perfect for spaces seeking a more inviting and traditional touch.

What makes it special isn’t solely the material quality but also how each design decision serves form and function. The combination of woven Ecofiber and marble elements shows Marantz’s dedication to crafting a speaker that emphasizes the experience of seeing and touching as much as listening. This philosophy positions the Grand Horizon as more than an audio device but a versatile component of the home’s overall design.

Innovating Sound and Style

The Marantz Grand Horizon redefines what a high-end speaker can be, presenting itself as an acoustic marvel and a design masterpiece. Its unique circular form, sustainable luxury materials, customizable sound tuning, and thoughtful interactivity elevate the typical wireless speaker experience—it embodies Marantz’s blend of heritage and forward-thinking design in home audio.

From motion-activated LEDs to tactile controls in the gold accents, Marantz has crafted a speaker for those who view audio equipment as more than mere utility. It’s a convergence of technology, art, and sustainable design—a statement for any discerning listener seeking luxury without compromise.

The post Experience 360 Degrees of Luxury Sound with the Marantz Grand Horizon first appeared on Yanko Design.