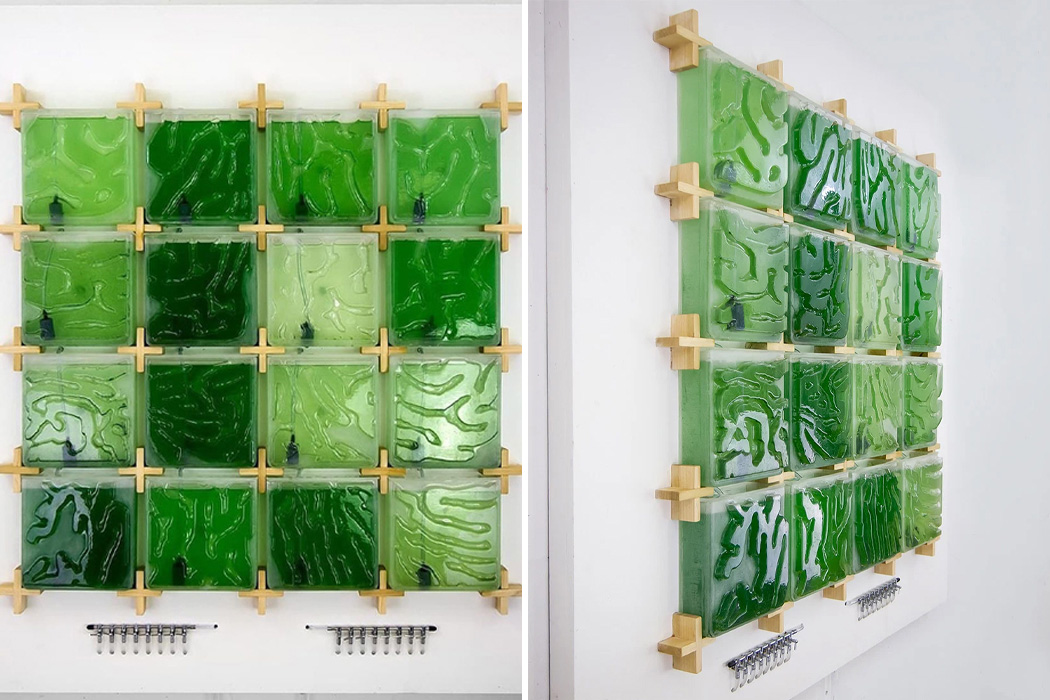

Modular homes have been on the rise. Even if we’re only dreaming, each one of us is searching high and low for our own prefabricated getaway somewhere far away in the woods and modular homes offer a feasible means to create our own dream cabin in the woods. Whether we’d like one for work-related retreats or for family holidays, Woonpioniers, an Amsterdam-based architecture, and design studio has created Indigo, a modular building system that designs homes to replicate one of your dreams.

Depending on the home you’d like to build with Woonpioniers, Indigo’s structure and shape may vary. Recently, Lia Harmsen collaborated with Woonpioniers to design her live-in workspace for sculpting. The finished custom two-floor home measures 861-square-feet and features fixed-end moment building practices that produce a beautiful, curved interior leading from the wall to the ceiling. The fixed-end moment frame of the home offers an open-air floor plan, giving complete access for the building’s interior layout to take shape, leaving behind the spatial restriction of support beams and partitions.

Inside, the topmost section of the pinewood sheets that make up the home’s wall curves and connects to the ceiling, producing beam-like support for the building’s structural forces without the physical need of additional beams. Woonpioniers built the bendable wooden sheets themselves, making small incisions in the wooden sheets until they curved to the desired shape. Below, pigmented concrete fills Indigo’s ground floor while the stairs and the upstairs bedroom is lined with ProFi flooring from solid timber and given a transparent coating for a finished look.

From the outside, Harmsen’s dark-as-night Indigo live-in workspace features floor-to-ceiling windows that cover the whole of the structure’s front and back facades. The abundance of natural light showcases the home’s floorplan, which features a small kitchenette, dining area, living room, and bathroom located below a staircase with integrated storage options that leads to the home’s loft bedroom.

Designer: Woonpioniers

From the exterior, Indigo appears to have a traditional frame, but a closer look showcases curving interior walls.

Indigo’s exterior facades are paneled with pinewood and connect to a metal roof.

The curved walls provide the loft with a cozy frame and an organic placement for the built-in skylight.

From both ends of the loft, Indigo features a triangular floor-to-ceiling window.

The materials used to build Indigo were chosen for their self-regulating properties were responsibly sourced for an overall minimal environmental impact.

The first floor of Harmsen’s Indigo features a small kitchenette and dining area on one side, and a woodfire oven delineates the kitchenette from the rest of the floor plan.

The polished concrete flooring is only found on the first floor and bathroom interiors.

Equipped with integrated staircase storage, Woonpioniers made clever use of the 861-square-feet on which Indigo rests.

The kitchenette’s countertop was built by Lia Harmsen herself.

Across the room from the kitchen, Indigo also features a small living area.