In the not-so-distant past, desktop computers were almost literal black boxes, closed and obscured from view. Although they’re still enclosed today to block the easy entry of dust and harmful particles, many desktop towers have adopted transparent designs that show everything inside.

This aesthetic is mostly to appeal to gamers who dress up their rigs with RGB lights and fancy-looking cooling systems, but the majority of the hardware you can see inside is hardly aesthetic (unless you go for that look). Graphics cards are slowly getting a facelift, but they still have a more technical and geeky look. This concept tries to challenge that status quo with a GPU design that could interest even non-gaming computer users.

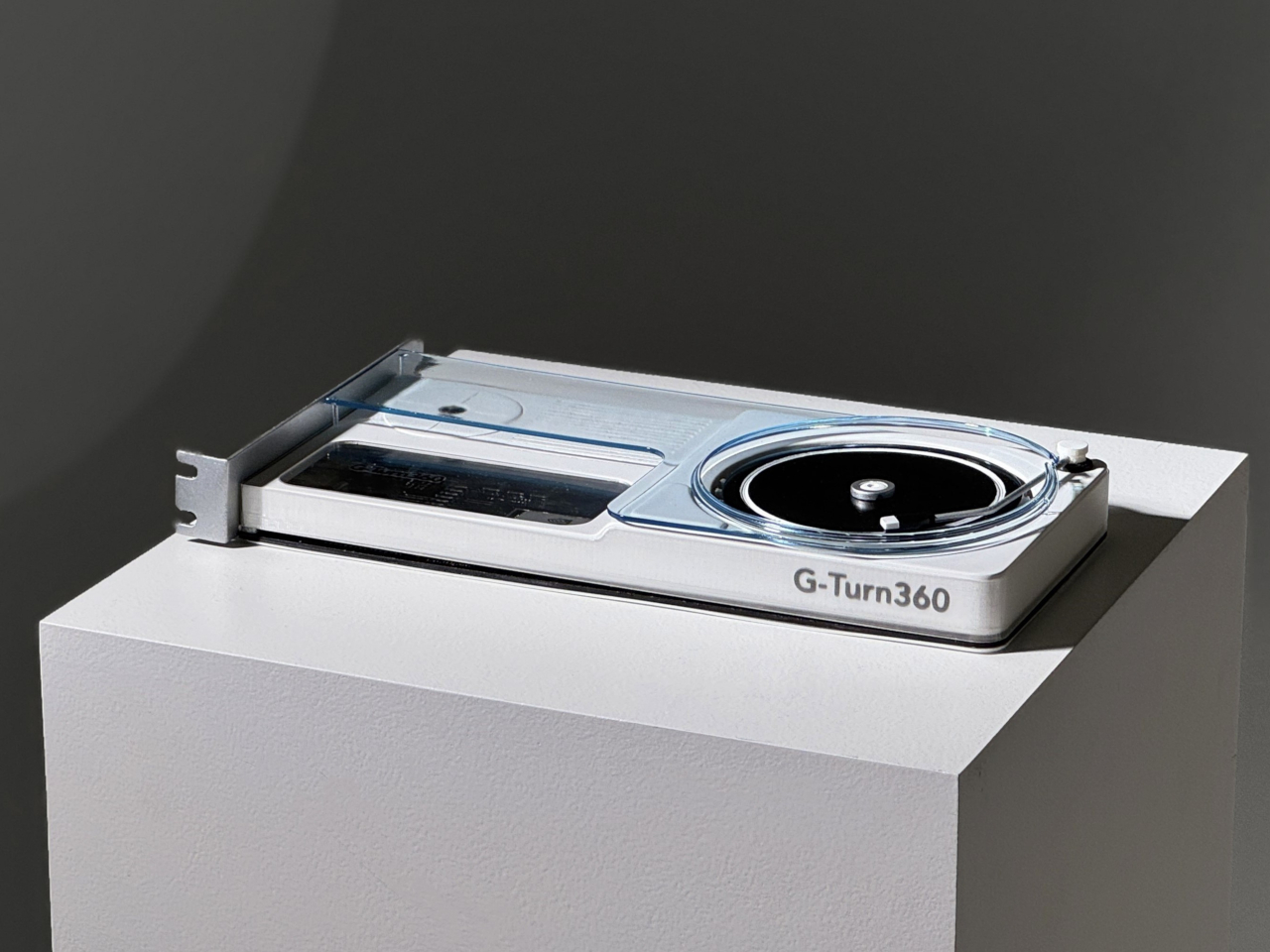

Designer: Seunghun Lee

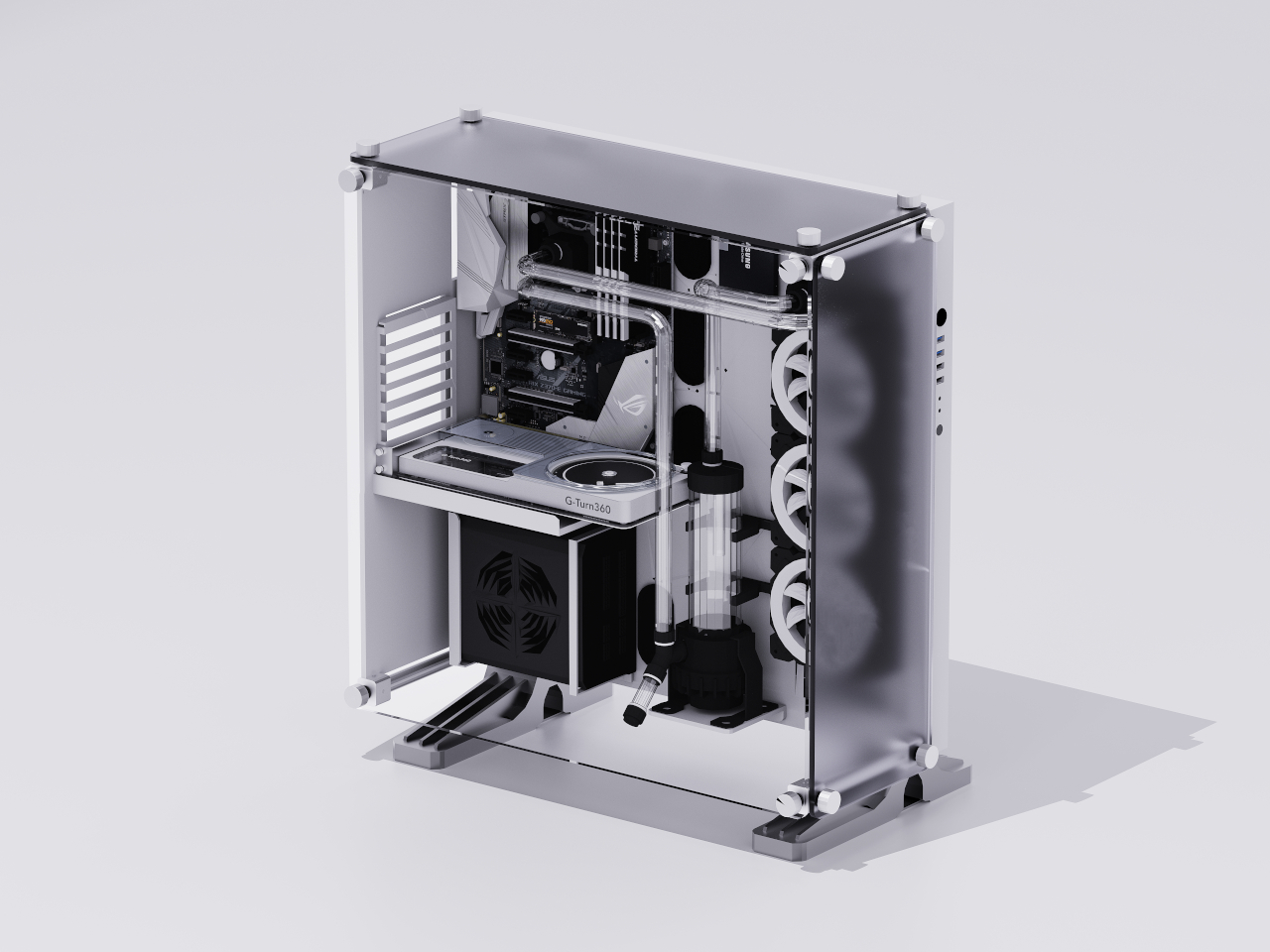

Of all the components inside a desktop computer, at least the ones built for gaming or heavy-duty creative work, the graphics card is the bulkiest, boxiest, and most visible one. Of course, that design is intentional because of the electronics it has to pack inside as well as the large fans that keep things from overheating. Such graphics cards today come with some RGB lighting or accents to make them look a little livelier, but the overall aesthetic remains the same.

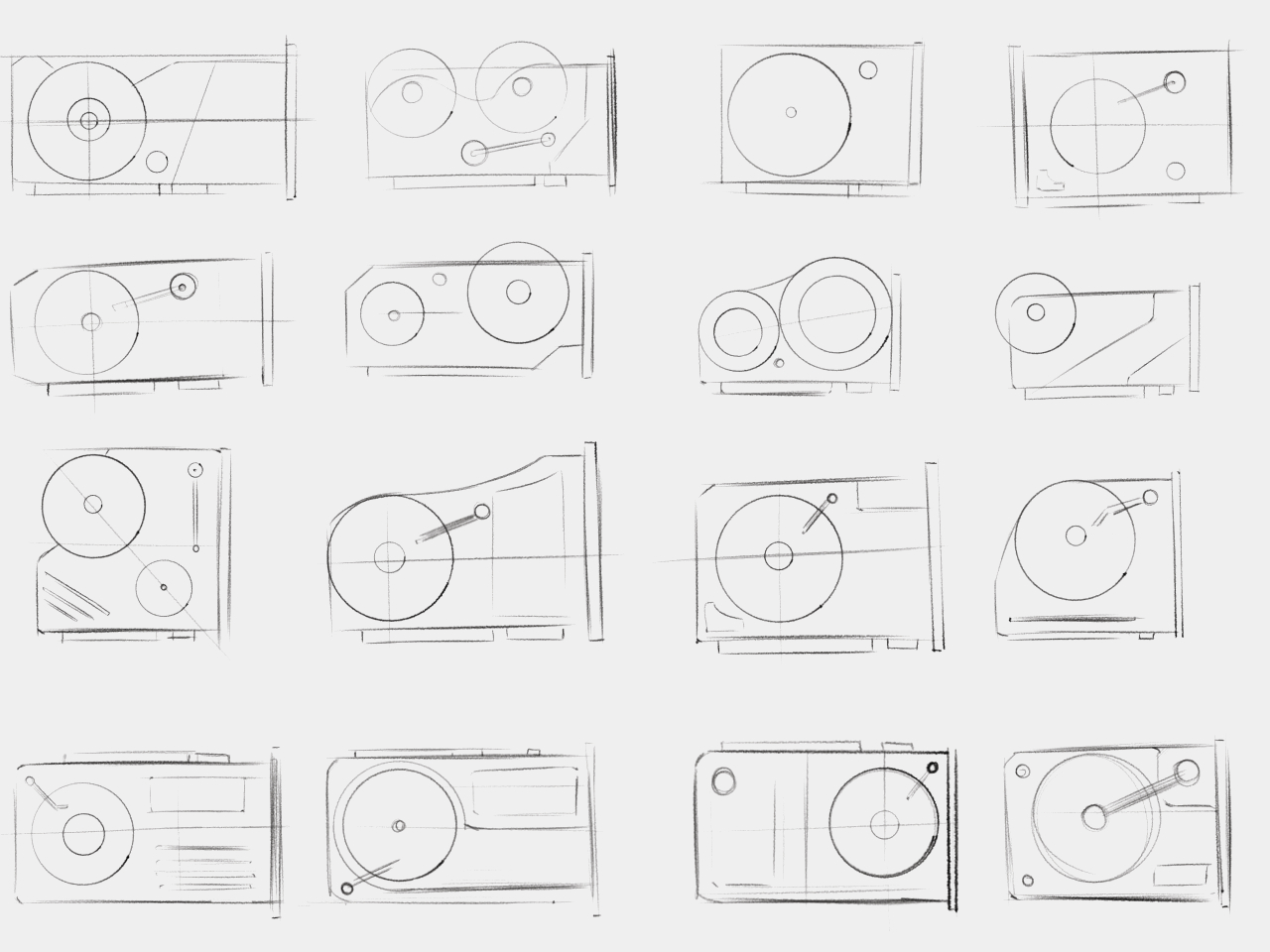

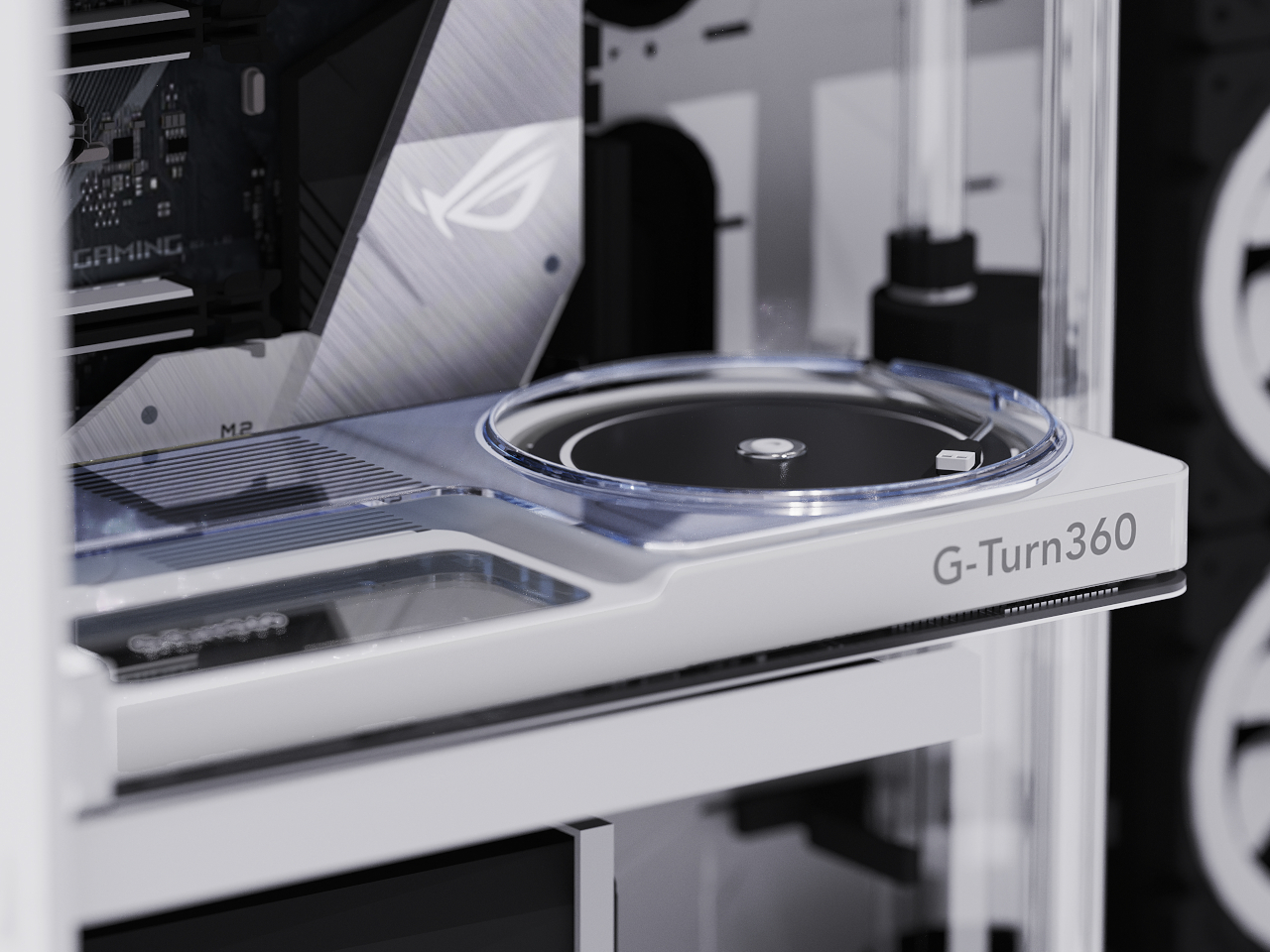

G-Turn360 is a concept design that tries to add some visual appeal by taking inspiration from a completely different product. It chose the turntable, now a staple of the retro movement, as the foundation of the GPU redesign, combining mechanical elements into a more pleasing composition using basic geometric shapes. The cooling fan, after all, is already a large circle, so why not use that form to represent a record player on a box?

The concept also goes beyond that simple association with the record player. It completely throws out the conventional LED lighting which, in addition to being over the top, also prevents visual consistency. In fact, the G-Turn360 embraces a lighter color scheme, which better fits desktop designs that are moving away from dark and black boxes commonly associated with gaming gear.

The result is a graphics card design that somehow looks both retro and futuristic at the same time, adopting a clean aesthetic that can appeal to a more diverse audience. That said, the G-Turn360 concept could be sacrificing performance and safety with its unconventional design, so it’s definitely not something that can simply be used without some modification and careful engineering.

The post Turntable-inspired graphics card concept adds a retro-futuristic flavor to desktops first appeared on Yanko Design.