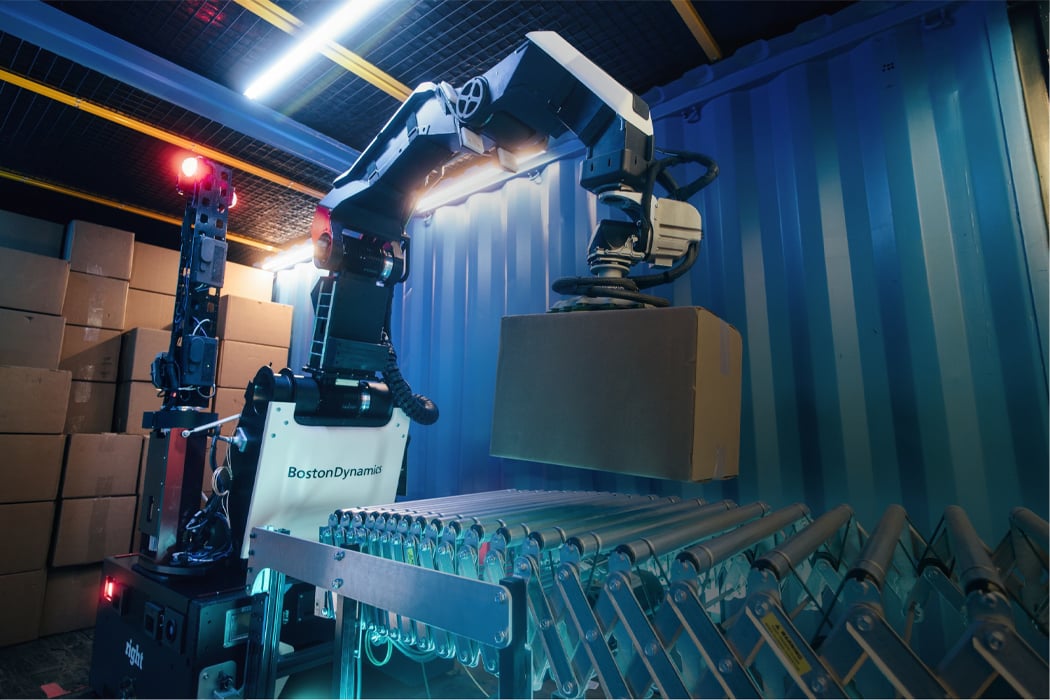

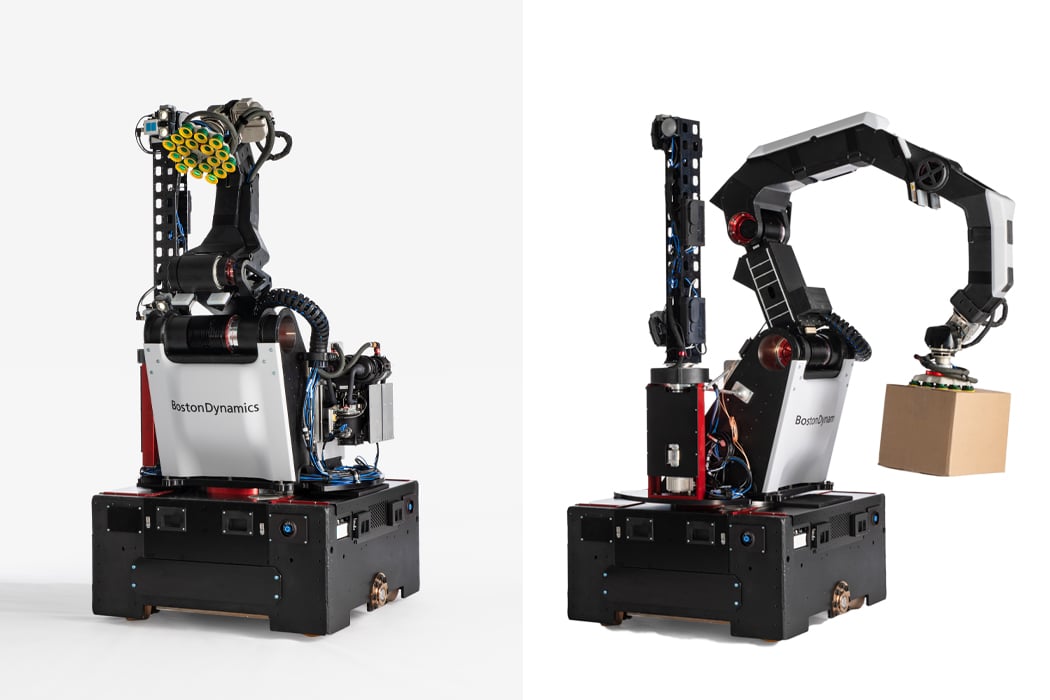

The world as we know it is changing, and robots are steadily taking over, a sci-fi fantasy that is soon turning into reality. Moving toward a healthier and more hands-off future does mean that technology is taking a lot of the work off our hands. Designers are building robots to take care of public service jobs primarily rooted in collecting, cleaning, and distributing. Recently debuting their public service bot, Samsung’s Bot Public does all of that and even winks.

The designers behind Samsung Bot Public built the public service robot to provide contact-free professional services in public spaces. Samsung Bot Public looks like the public service robot we’ve come to expect based on all the sci-fi movies we’ve seen, capable of shifting into different configurations for different service jobs. The versatile base of Samsung Bot Public works as a universal charging base that can register other mounted domains to complete various tasks throughout the day.

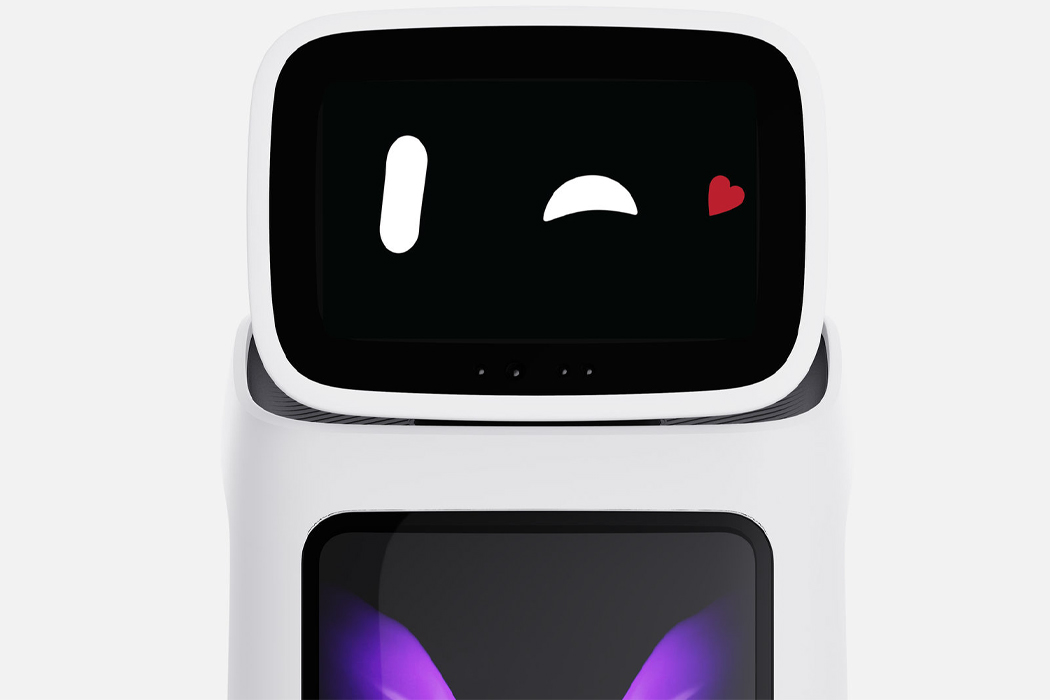

The different domains are configured according to the task at hand– while one domain features a three-tier shelving unit, another features only a display screen and slim carrying tray. The most sought-after public service bots in circulation today are serving, delivery, and guide robots, and these were the three services prioritized. While the robots are generally programmed and made for free movement, their software is still accessible through external devices and storage systems. If serving the public wasn’t enough for the robot’s plate, each interaction is also met with a wink and smile.

Designer: Samsung

The Samsung Bot Public’s design hinges on the main base platform that adapt to each changing domain.

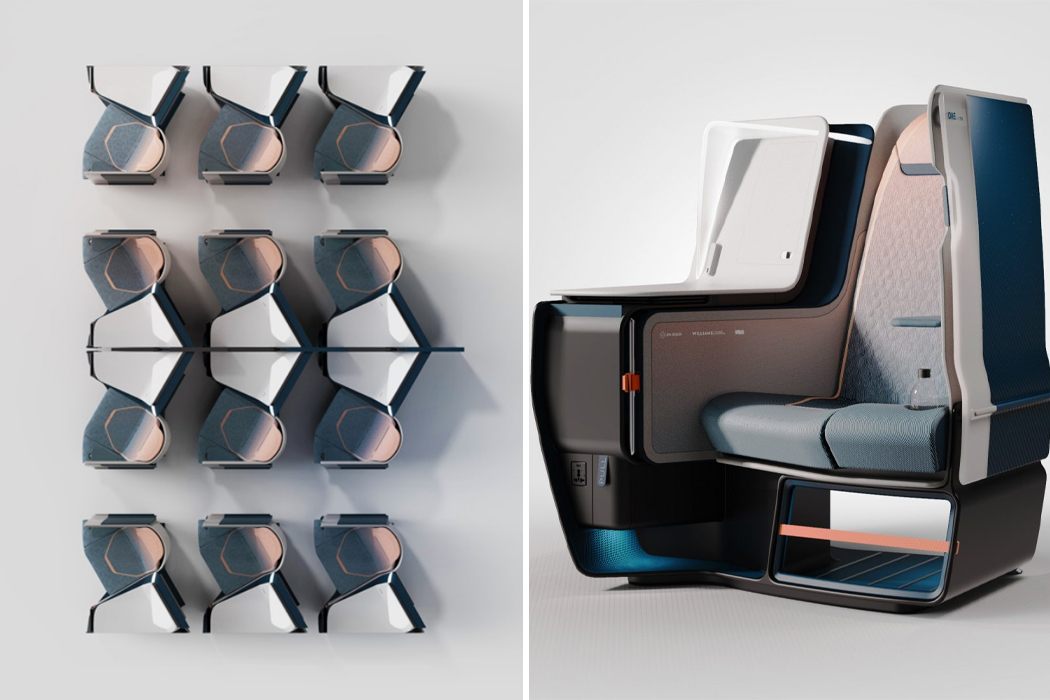

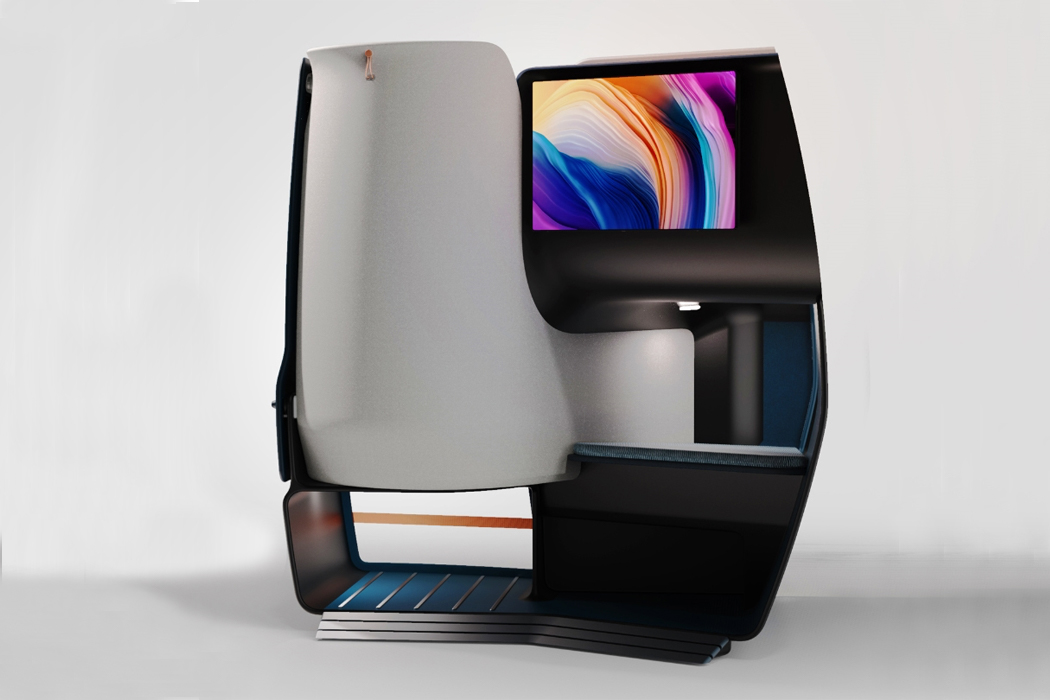

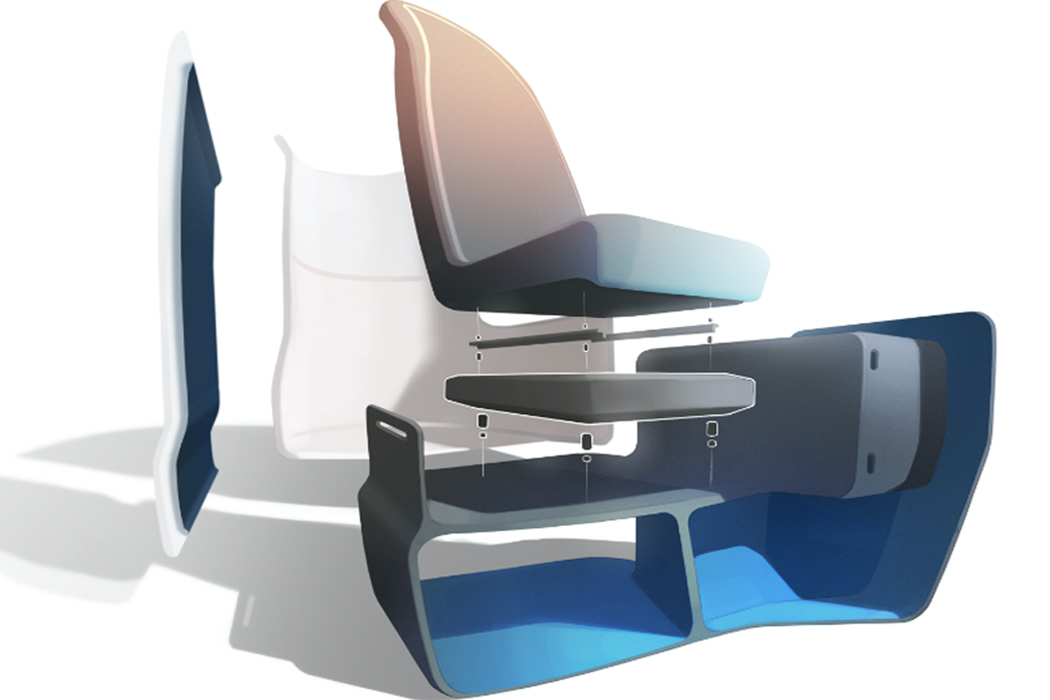

One domain features a large panel display screen, built-in charging port, and small tray table.

Another domain seems to indicate collecting and distribution duties with a three-tier shelving unit and drawers.

Each Samsung Bot Public comes with an emergency stop button and a rear LED display panel.

The original domain’s drawers pull out to create more storage space for collecting and delivering.

With all of this, Samsung Bot Public also ends each interaction with a good ole robot wink.

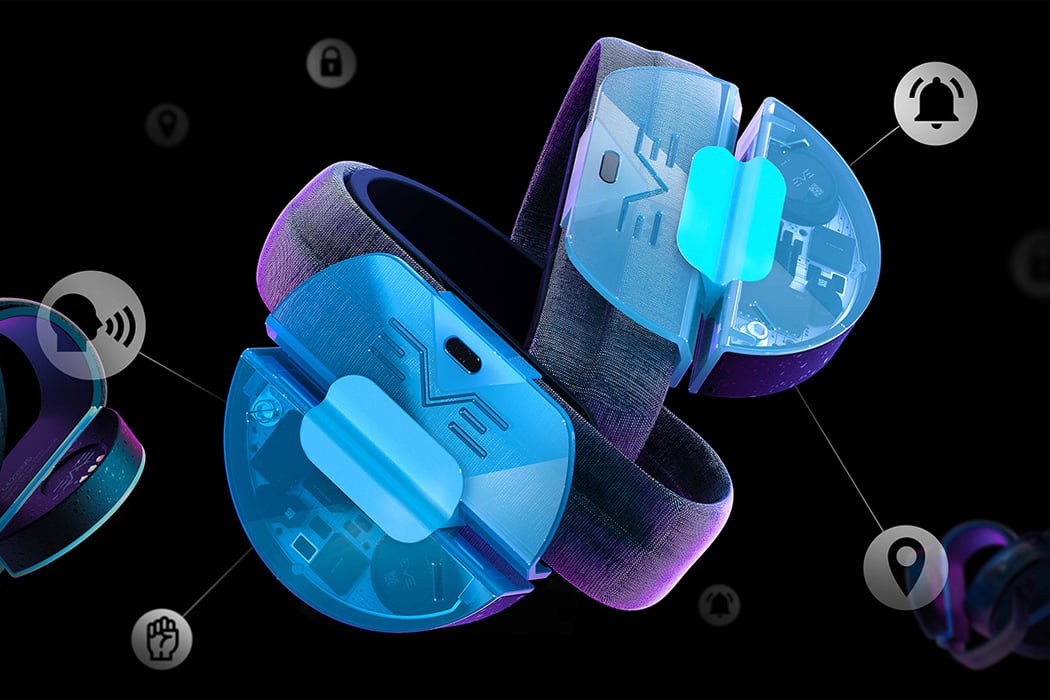

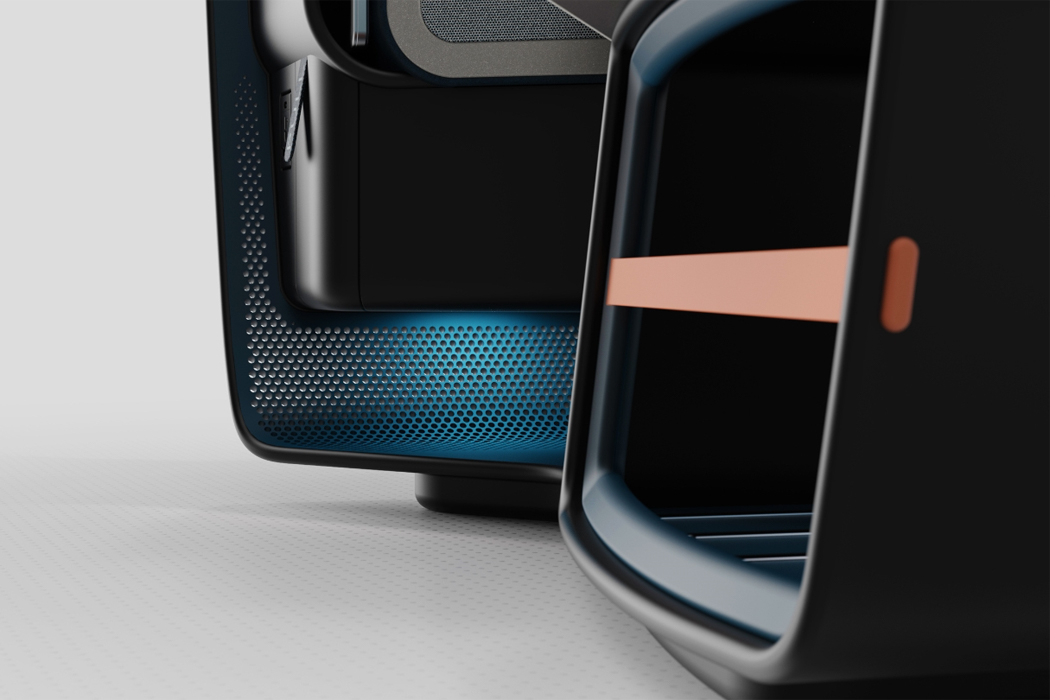

The extra storage bin provides travelers with supplemental security when stowing sway their bags, thanks to an elastic strap.

The extra storage bin provides travelers with supplemental security when stowing sway their bags, thanks to an elastic strap.